High-temperature molybdenum alloy and preparation method thereof

A molybdenum alloy, high temperature technology, applied in the new high temperature molybdenum alloy and its preparation field, can solve the problems of poor plasticity and low density at room temperature, and achieve the effect of high recrystallization temperature, good performance and industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A high-temperature molybdenum alloy provided in this embodiment includes molybdenum, potassium, silicon and unavoidable impurities, wherein the content of potassium is 500-552 ppm times that of molybdenum, and the content of silicon is 8.58 ppm of that of molybdenum. ~10.8ppm times.

[0061] A kind of preparation method as aforementioned high-temperature molybdenum alloy comprises the steps:

[0062] Take 100ml of potassium silicate stock solution with a mass fraction of 23%, add 14.5g of potassium oxalate and 9.15g of potassium hydroxide, mix well, dilute to 4000ml, take 770ml from it and dilute to 4000ml again, and record it as silicon potassium solution, reserve, more The second dilution can ensure the full dissolution of potassium silicate, potassium oxalate and potassium hydroxide;

[0063] Get the described silicon-potassium solution of 800ml, add the molybdenum dioxide powder that 2.5kg obtains by reducing ammonium molybdate, after stirring and dispersing, dry, ...

Embodiment 2

[0071] A high-temperature molybdenum alloy provided in this embodiment includes molybdenum, potassium, silicon and unavoidable impurities, wherein the content of potassium is 552-555 ppm times that of molybdenum, and the content of silicon is 8.58 ppm of that of molybdenum. ~10.8ppm times.

[0072] A kind of preparation method as aforementioned high-temperature molybdenum alloy comprises the steps:

[0073] Take 100ml of potassium silicate stock solution with a mass fraction of 27%, add 14.5g potassium oxalate and 9.15g potassium hydroxide, mix well, dilute to 4000ml, take 770ml from it and dilute to 4000ml again, record it as silicon potassium solution, and set aside;

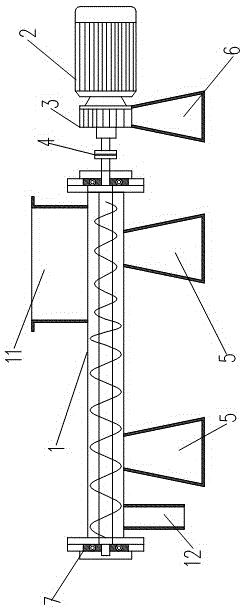

[0074] Get the described silicon-potassium solution of 4000ml, add the molybdenum dioxide powder that 12.5kg obtains by reducing ammonium molybdate, after stirring and dispersing, dry, in such as figure 1 Crushed and sieved in the shown stirring pulverizer to obtain doped molybdenum dioxide powder;

[0075] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Recrystallization temperature | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com