Method for preparing sulfydryl modified ferroferric oxide/silicon dioxide magnetic nanoparticles

A technology of magnetic nanoparticles and ferroferric oxide, which is applied in the field of medical materials, can solve problems such as cumbersome process steps, solvent methanol is volatile, and human poisoning, and achieves the effects of simple operation process, good dispersion performance, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing the mercapto-modified ferric oxide / silicon dioxide magnetic nanoparticles of the present invention comprises the following steps:

[0042] (1) Take 1mmol of FeCl 3 ·6H 2 O in a beaker, then add 30ml of ethylene glycol and 2g of polyethylene glycol 2000, stir magnetically until uniformly dispersed, then continue to add 3g of anhydrous sodium acetate, and stir to obtain a uniformly dispersed mixed solution. Then add the mixed solution into the autoclave, raise the temperature to 200°C and react for 6 hours, after the reaction is completed, water cool to room temperature, magnetically separate, wash the solid matter obtained after separation with alcohol several times, and then put it in a 60°C drying oven under vacuum Dry to obtain magnetic ferric oxide particles.

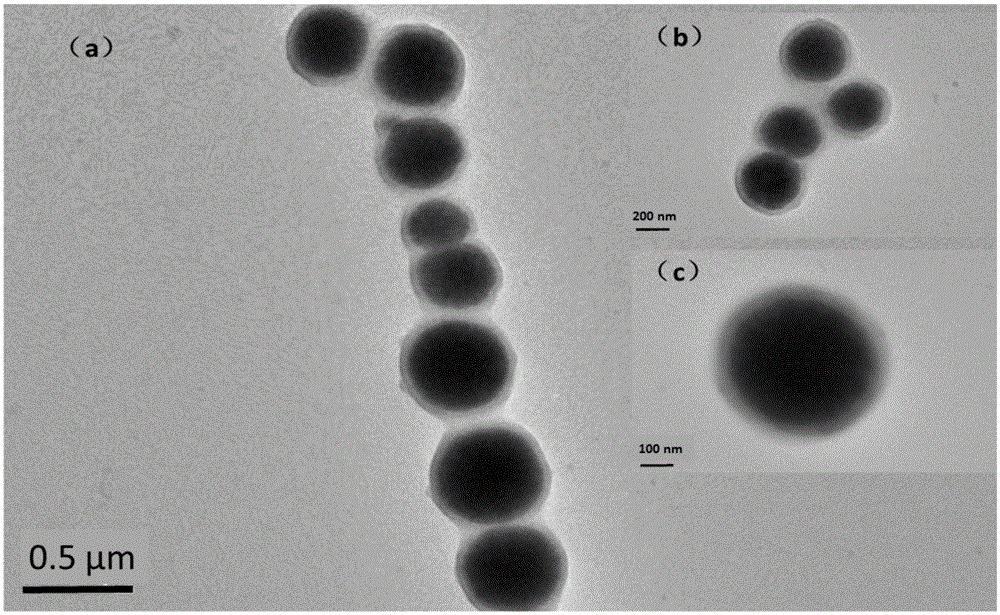

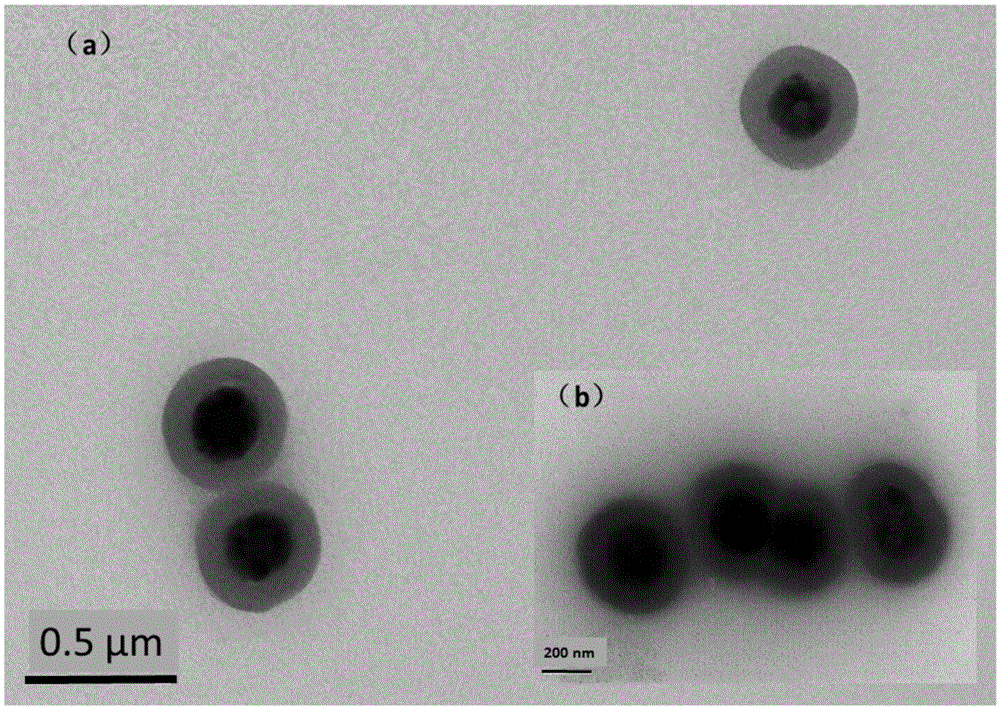

[0043] (2) Disperse 50 mg of the magnetic ferric iron tetroxide particles prepared in step (1) in 75 mL of ethanol solution, sonicate for 40 min, continue to add 23.5 mL of deionized w...

Embodiment 2

[0047] A method for preparing the mercapto-modified ferric oxide / silicon dioxide magnetic nanoparticles of the present invention comprises the following steps:

[0048] (1) Take 1mmol of FeCl 3 ·6H 2 O in a beaker, then add 30ml of ethylene glycol and 2g of polyethylene glycol 2000, stir magnetically until uniformly dispersed, then continue to add 3g of anhydrous sodium acetate, and stir to obtain a uniformly dispersed mixed solution. Then add the mixed solution into the autoclave, raise the temperature to 200°C and react for 6 hours, after the reaction is completed, water cool to room temperature, magnetically separate, wash the solid matter obtained after separation with alcohol several times, and then put it in a 60°C drying oven under vacuum Dry to obtain magnetic ferric oxide particles.

[0049] (2) Disperse 50 mg of the magnetic ferric iron tetroxide particles prepared in step (1) in 150 mL of ethanol solution, sonicate for 40 min, then add 47 mL of deionized water and...

Embodiment 3

[0053] A method for preparing the mercapto-modified ferric oxide / silicon dioxide magnetic nanoparticles of the present invention comprises the following steps:

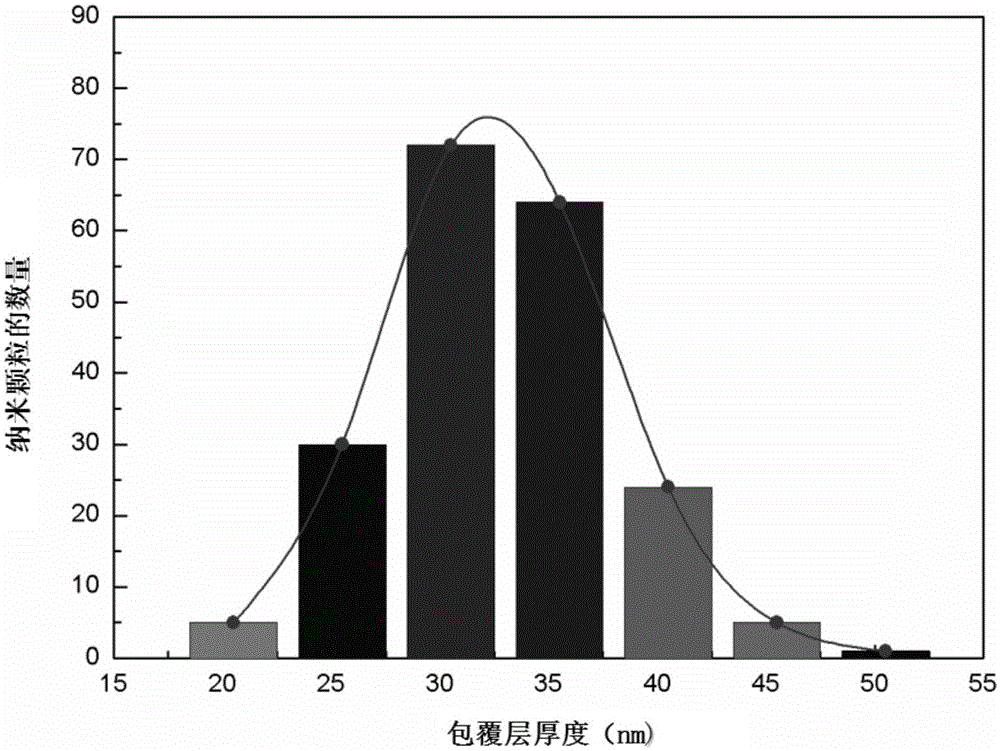

[0054] (1) Take 1mmol of FeCl 3 ·6H 2 O in a beaker, then add 30ml of ethylene glycol and 2g of polyethylene glycol 2000, stir magnetically until uniformly dispersed, then continue to add 3g of anhydrous sodium acetate, and stir to obtain a uniformly dispersed mixed solution. Then add the mixed solution into the autoclave, raise the temperature to 200°C and react for 6 hours, after the reaction is completed, water cool to room temperature, magnetically separate, wash the solid matter obtained after separation with alcohol several times, and then put it in a 60°C drying oven under vacuum Dry to obtain magnetic ferric oxide particles. The particle size distribution is shown in Figure 5 As shown, the average particle size is 157nm.

[0055] (2) Disperse 50 mg of the magnetic ferric iron tetroxide particles prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com