A kind of preparation method of cefcapene hydrochloride

A technology of cefcapene hydrochloride and carboxylic acid, applied in the direction of organic chemistry and the like, can solve the problems such as the destruction of the core structure of cefene carboxylic acid, easy generation of by-products and impurities, affecting yield and quality, etc., to avoid ring opening Destructive effects, reduced dissolution time, improved yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

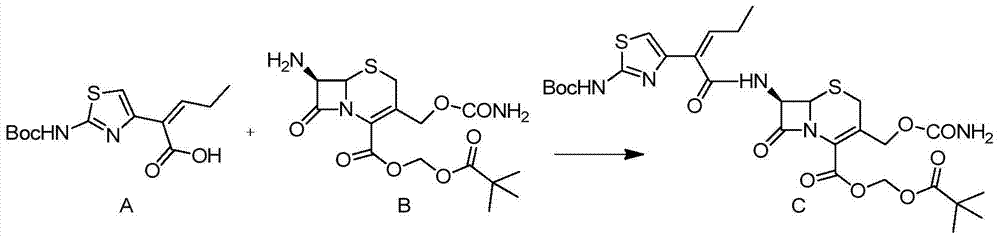

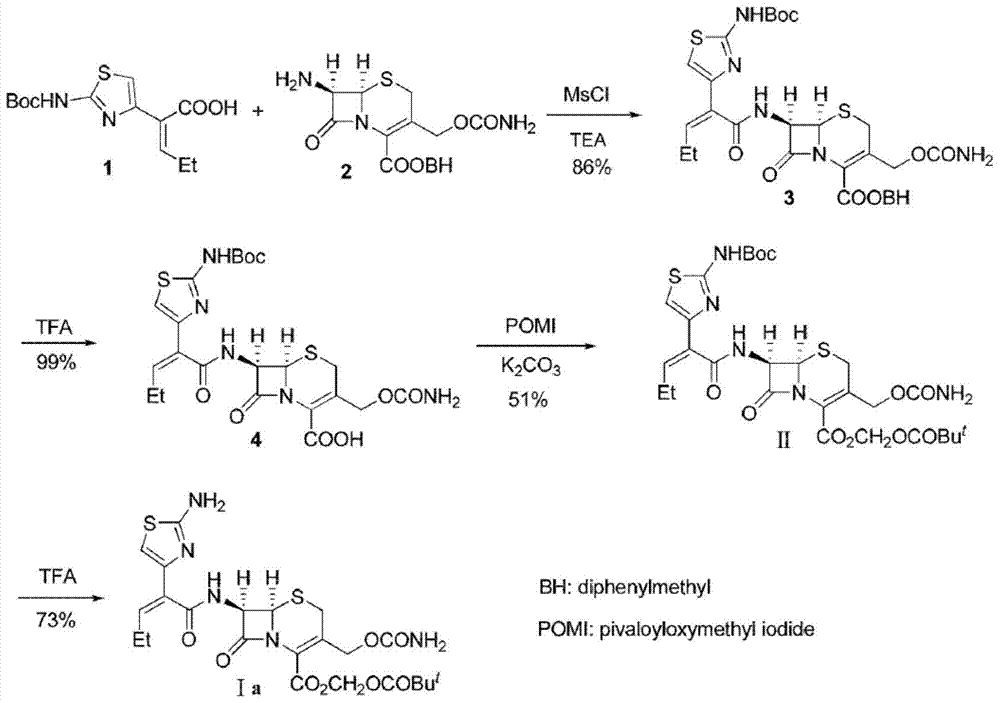

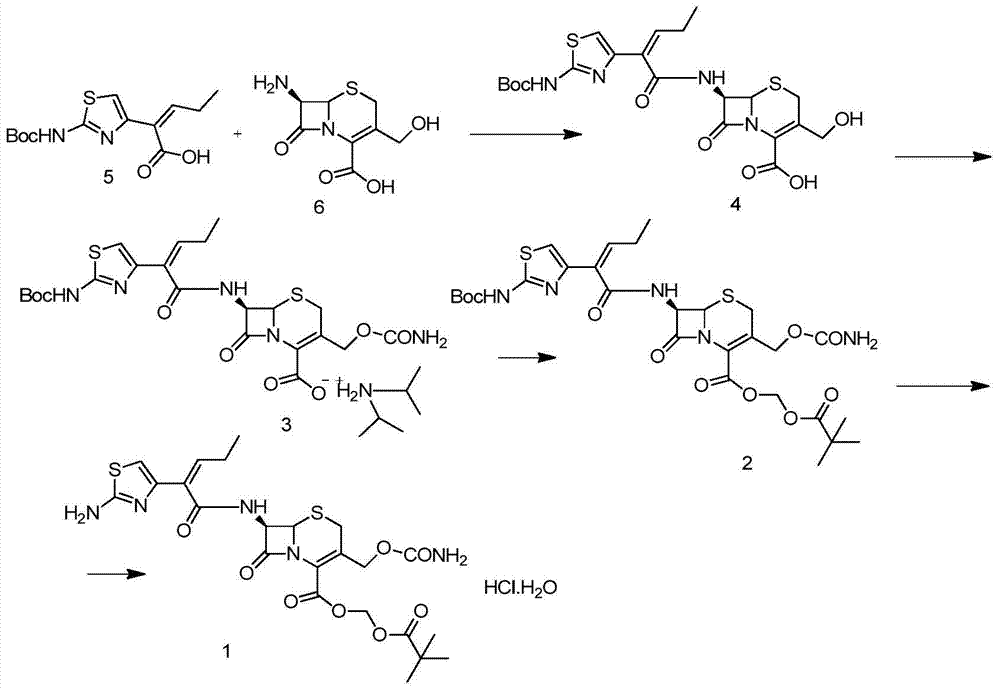

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: the synthesis of 7-amino-3-hydroxymethyl cephalosporanic acid (7-DACA, compound 6)

[0042] Weigh 27.2g (0.1mol) of 7-ACA, add 50mL methanol and 50mL water, add 3.0g tetra-n-butylammonium chloride and stir to dissolve at -5-5°C, and add 2mol / L hydrogen dropwise at this temperature Sodium oxide solution 105mL, after dripping, keep the temperature and continue to stir for 0.5-1 hour, then add 30% hydrochloric acid to adjust the pH to neutral, precipitate a solid, suction filter, wash with absolute ethanol, dry to obtain 20.7g of off-white solid, and collect The yield was 90.1%, the HPLC purity analysis was 97.35% (area normalization method), and the lactone impurity was 0.33%.

Embodiment 2

[0043] Embodiment 2: the synthesis of 7-amino-3-hydroxymethyl cephalosporanic acid (7-DACA, compound 6)

[0044] Weigh 27.2g (0.1mol) of 7-ACA, add 50mL methanol and 50mL water, add 1.5g tetra-n-butylammonium chloride and stir to dissolve at -5-5°C, and add 2mol / L hydrogen dropwise at this temperature Sodium oxide solution 105mL, after dripping, keep the temperature and continue to stir for 0.5-1 hour, then add 30% hydrochloric acid to adjust the pH to neutral, precipitate a solid, suction filter, wash with absolute ethanol, dry to obtain 19.6g of off-white solid, and collect The yield was 85.2%, the HPLC purity analysis was 95.58% (area normalization method), and the lactone impurity was 0.56%.

Embodiment 3

[0045] Embodiment 3: the synthesis of 7-amino-3-hydroxymethyl cephalosporanic acid (7-DACA, compound 6)

[0046] Weigh 27.2g (0.1mol) of 7-ACA, add 50mL of methanol and 50mL of water, add 1.5g of benzyltrimethylammonium chloride and stir to dissolve at -5-5°C, and add 2mol / L of Sodium hydroxide solution 105mL, after dropping, keep the temperature and continue to stir for 0.5-1 hour, then add 30% hydrochloric acid to adjust the pH to neutral, a solid is precipitated, suction filtered, washed with absolute ethanol, and dried to obtain 18.6g of off-white solid, Yield 80.5%, HPLC purity analysis 93.8% (area normalization method), lactone impurity 0.88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com