A kind of solar cell composite back film and preparation method thereof

A technology for solar cells and composite films, applied in the field of solar cells, can solve the problems of poor anti-fouling ability, poor heat dissipation, material vaporization, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

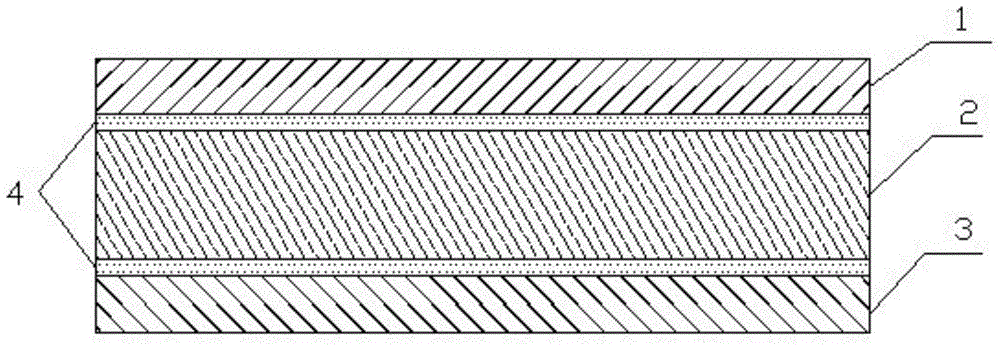

[0036] like figure 1 As shown, a composite back film for solar cells comprises a first back film 1, a second back film 2, a third back film 3, between the first back film 1 and the second back film 2, the second back film 2 There is also an adhesive layer 4 between the third back film 3 and the first back film 1 is adjacent to the EVA adhesive film of the solar cell. Moreover, the first back film is a polytetrafluoroethylene film; the second back film is a composite film made of polyethylene terephthalate film and fumed silica; the third back film is polycarbonate-zirconia -Composite membrane composed of polytetrafluoroethylene.

[0037] In addition, the zirconia in the third back film 3 is nano zirconia. The zirconia is nano zirconia modified by hexafluoropropylene oxide oligomer surfactant, titanate coupling agent and polymer compatibilizer. Polycarbonate is coated on the surface of the surface active agent zirconia to form a structure with zirconia as the core and polycarb...

Embodiment 2

[0041] refer to figure 1 , a solar cell composite back film, comprising a first back film 1, a second back film 2, a third back film 3, between the first back film 1 and the second back film 2, between the second back film 2 and the second back film There is also an adhesive layer 4 between the three back films 3, and the first back film 1 is adjacent to the EVA adhesive film of the solar cell. Moreover, the second back film is a composite film composed of polyethylene terephthalate film and fumed silica; the first and third back films are made of polycarbonate-zirconia-polytetrafluoroethylene Composite film.

[0042] In addition, the zirconia in the first and third back films 3 is nano zirconia. The zirconia is nano zirconia modified by hexafluoropropylene oxide oligomer surfactant, titanate coupling agent and polymer compatibilizer.

[0043] The solar battery back film provided by the invention uses a modified polytetrafluoroethylene film, which has superior electrical pe...

Embodiment 3

[0045] A preparation method for a solar cell composite back film, characterized in that: comprising the following steps:

[0046] 1) Zirconia modification: Dry the nano-zirconia at 110°C for 30 minutes, then put it into a container filled with toluene solvent, ultrasonically disperse it for 20 minutes, then add a titanate coupling agent (the weight accounts for 0.5% of the weight of the nano-zirconia) ), kept in a water bath at 100°C for 3 hours, cooled naturally, filtered with suction, dried, and the product was placed in a desiccator for subsequent use;

[0047] 2) Preparation of zirconia-polycarbonate composite particles: add the modified zirconia to deionized water, acrylic polymer compatibilizer (accounting for 2.0% of the weight of nano zirconia), hexafluoropropylene oxide oligomer type Surfactant (accounting for 0.6% of the weight of nanometer zirconia), stirred at normal temperature for 30min, the copolymer was dispersed evenly, and the temperature was raised to 60°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com