A kind of rare earth metal alkyl sulfide nanomaterial and preparation method thereof

A technology of rare earth metals and nanomaterials, applied in the chemical industry, can solve problems such as poor compatibility and restrictions on the application and development of rare earth metal compounds, and achieve the effects of easy-to-obtain raw materials, simple preparation methods, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Weigh 9.0g of gum rosin and 6.0g of calcium carbonate and grind evenly, add 120mL of ethanol, stir mechanically for 15min, add 6.4g of bis(γ-triethoxypropyl) disulfide, and dissolve the solution with 10% sodium hydroxide solution The pH value of the solution was adjusted to 10, and after stirring for 2 hours at room temperature, 10% hydrochloric acid solution was added dropwise to adjust the pH value of the solution to 2, and the solution was washed by suction filtration;

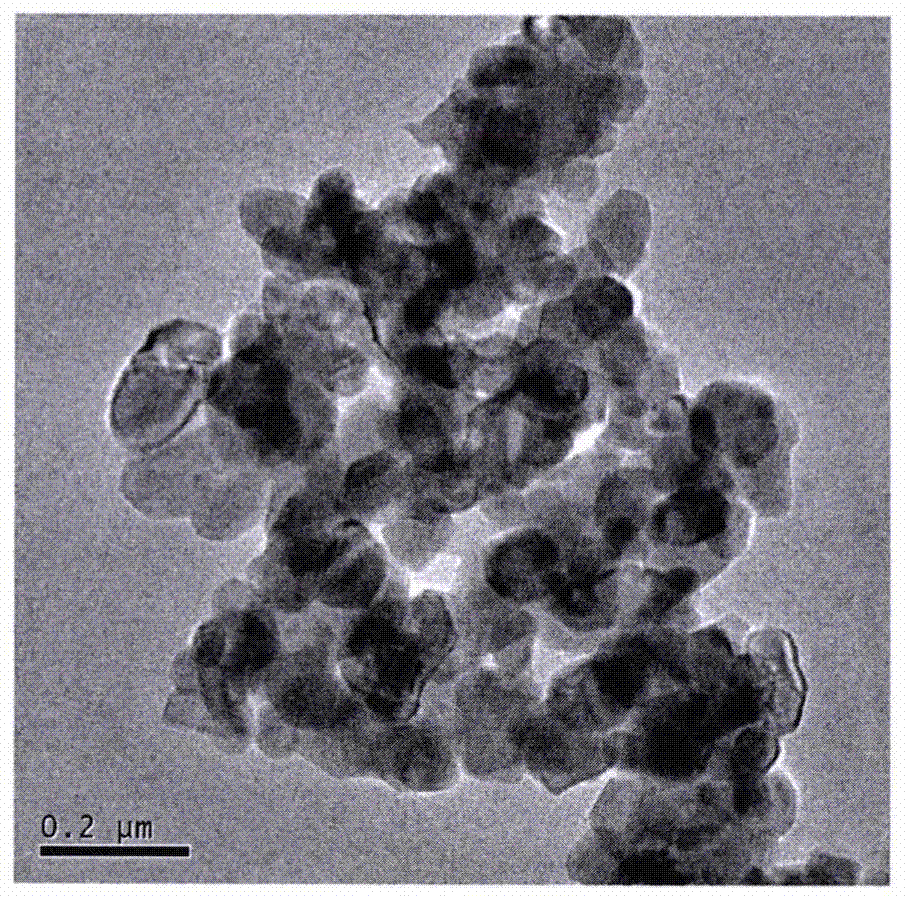

[0034] The solid obtained after suction filtration is transferred to a 250mL four-neck flask with a stirring device, a temperature control device and a reflux device, 100mL of water is added, mechanically stirred to disperse evenly, 0.4g hexanethiol and 0.2g polyethylene glycol are added, and then Add dropwise 32g of lanthanum nitrate solution with a mass percentage concentration of 10%, adjust the pH value of the solution to 6 with 10% ammonia solution, heat up to 90°C for reflux reaction for 60min, a...

Embodiment 2

[0037] Weigh 9.0g of gum rosin and 6.0g of calcium carbonate and grind evenly, add 120mL of ethanol, stir mechanically for 15min, add 8.2g of bis(γ-triethoxypropyl)tetrasulfide, and dissolve the solution with 10% sodium hydroxide solution The pH value of the solution was adjusted to 10, and after stirring for 2 hours at room temperature, 10% hydrochloric acid solution was added dropwise to adjust the pH value of the solution to 2, and the solution was washed by suction filtration;

[0038] The solid obtained after suction filtration is transferred to a 250mL four-neck flask with a stirring device, a temperature control device and a reflux device, 100mL of water is added, mechanically stirred to disperse evenly, 0.4g hexanethiol and 0.2g polyethylene glycol are added, and then Add dropwise 27.5g of yttrium nitrate solution with a mass percentage concentration of 10%, adjust the pH value of the solution to 7 with 10% ammonia solution, heat up to 90°C for reflux reaction for 60min...

Embodiment 3

[0041] Weigh 9.0g gum rosin and 10.0g calcium carbonate and grind evenly, add 120mL ethanol, mechanically stir for 15min, add 9.5g bis(γ-triethoxypropyl) disulfide, and dissolve the solution with 10% sodium hydroxide solution The pH value of the solution was adjusted to 10, and after stirring for 2 hours at room temperature, 10% hydrochloric acid solution was added dropwise to adjust the pH value of the solution to 2, and the solution was washed by suction filtration;

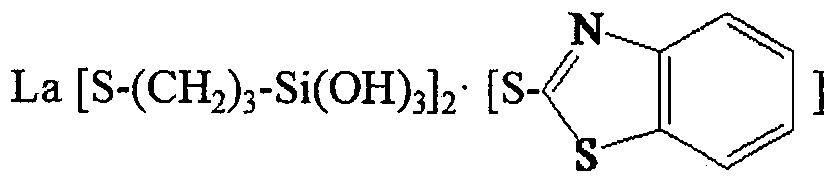

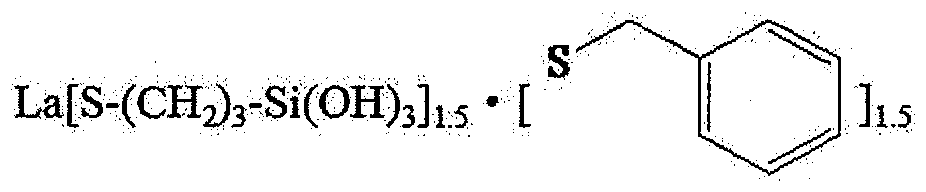

[0042] Transfer the solid obtained after suction filtration to a 250mL four-neck flask equipped with a stirring device, a temperature control device and a reflux device, add 100mL of water, mechanically stir and disperse evenly, add 3.3g of 2-mercaptophenylprophiazole and 0.5g of polyethylene glycol Glycol, then dripping 64g mass percentage concentration is the lanthanum nitrate solution of 10%, adjust the pH value of solution to 8 with 30% ammonia solution, heat up to 90 ℃ of reflux reaction 90min, after coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com