Tritepenoidic acid active site of ganoderma lucidum, method for preparing tritepenoidic acid active site and application thereof

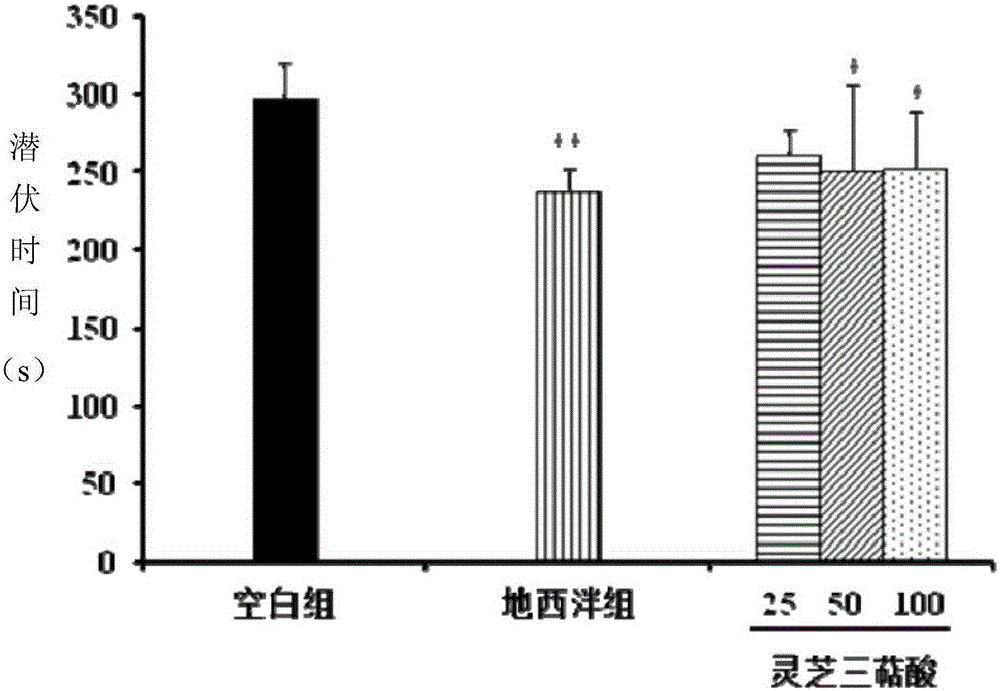

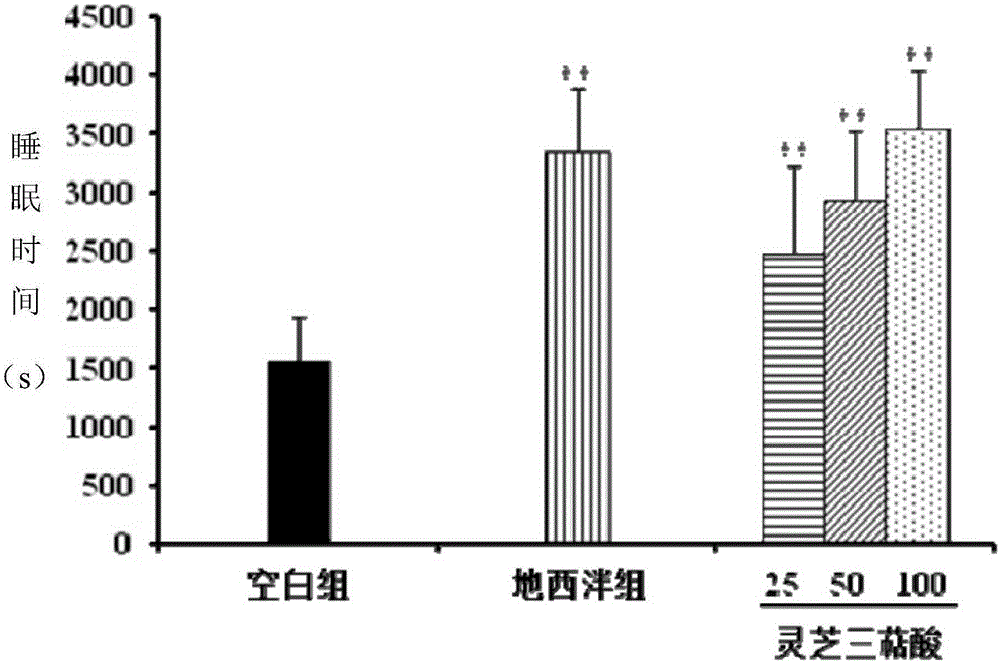

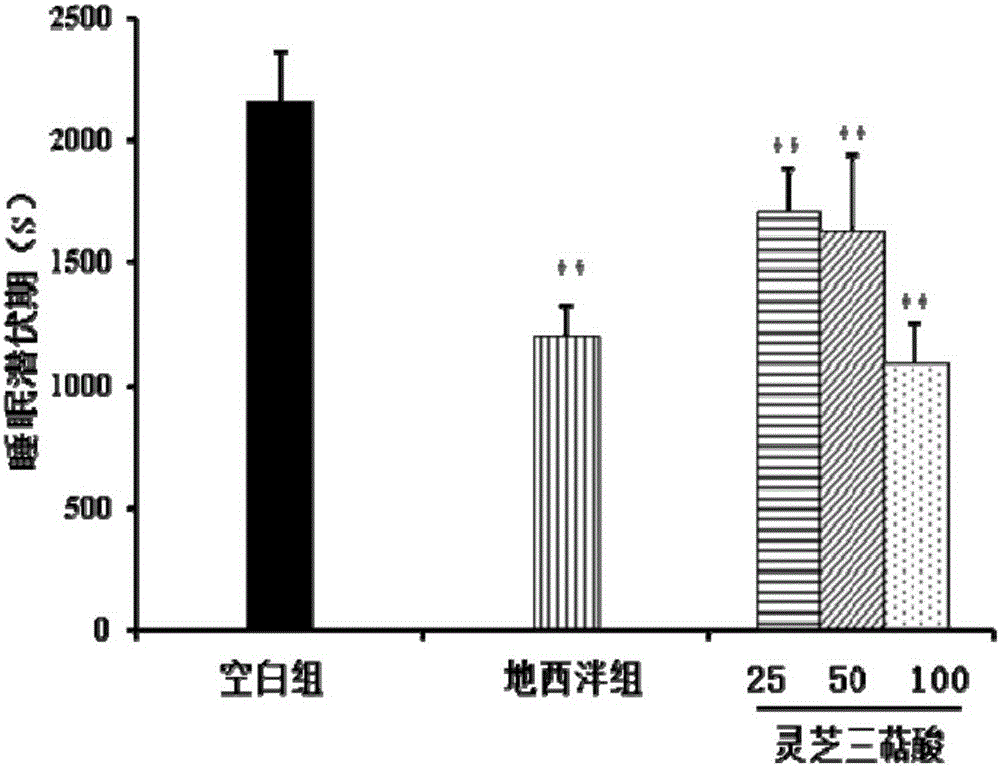

A technology of ganoderma triterpene acids and active parts, which is applied in the field of ganoderma lucidum extract, can solve the problems of unrefined ganoderma lucidum extract and unclear active and functional components, and achieve the benefits of market promotion and utilization, obvious sedative and tranquilizing effect, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 (preparation of ganoderma triterpene acid active site)

[0044] (1) Take Ganoderma lucidum fruiting body medicinal material (Zhejiang Wuyangtang Pharmaceutical Co., Ltd.), dry at 65°C, pulverize, and pass through a 100-mesh sieve to obtain dry powder; add distilled water to the dry powder at a material-to-liquid ratio of 1g: 20mL, and heat at a temperature of 50°C and pH5. 5, add 3.0% of the compound enzyme relative to the mass of the dry powder, the compound enzyme is composed of 50% neutral protease, 25% cellulase and 25% pectinase in percentage by weight, and the enzymolysis time is 6h. Enzyme, cooling, suction filtration, obtain enzymatic hydrolysis solution, set aside;

[0045] (2) Take the enzymolysis solution prepared in the above step (1), add petroleum ether to extract and remove fat, then continue to add ethyl acetate to the enzymolysis solution after degreasing to extract, to obtain the extraction part of ethyl acetate, and evaporate the ethyl ac...

Embodiment 2

[0049] Embodiment 2 (preparation of ganoderma triterpene acid active site)

[0050] (1) Take Ganoderma lucidum fruiting body medicinal material (Zhejiang Wuyangtang Pharmaceutical Co., Ltd.), dry at 65°C, pulverize, and sieve through a 100-mesh sieve to obtain dry powder; add distilled water to the dry powder at a material-to-liquid ratio of 1g︰15mL, and heat at a temperature of 40°C and pH4. Under the condition of 0, add 2.0% compound enzyme relative to the mass of the dry powder, the compound enzyme is composed of 30% neutral protease, 35% cellulase and 35% pectinase in weight percentage, the enzymolysis time is 5h, and the Enzyme, cooling, suction filtration, obtain enzymatic hydrolysis solution, set aside;

[0051] (2) Take the enzymolysis solution prepared in the above step (1), add petroleum ether to extract and remove fat, then continue to add ethyl acetate to the enzymolysis solution after degreasing to extract, to obtain the extraction part of ethyl acetate, and evapo...

Embodiment 3

[0055] Embodiment 3 (preparation of ganoderma triterpene acid active site)

[0056] (1) Take Ganoderma lucidum fruiting body medicinal material (Zhejiang Wuyangtang Pharmaceutical Co., Ltd.), dry at 65°C, pulverize, and pass through a 100-mesh sieve to obtain dry powder; add distilled water to the dry powder at a material-to-liquid ratio of 1g: 25mL, and heat at a temperature of 60°C and pH6. Under the condition of 0, add 4.0% compound enzyme relative to the mass of the dry powder, the compound enzyme is composed of 80% neutral protease, 10% cellulase and 10% pectinase in weight percentage, the enzymolysis time is 7h, and the Enzyme, cooling, suction filtration, obtain enzymatic hydrolysis solution, set aside;

[0057] (2) Take the enzymolysis solution prepared in the above step (1), add petroleum ether to extract and remove fat, then continue to add ethyl acetate to the enzymolysis solution after degreasing to extract, to obtain the extraction part of ethyl acetate, and evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com