Flexible thin film electrode material and preparation method thereof

A technology of flexible thin film and electrode materials, which is applied in the field of capacitors, can solve the problems of small capacity of pseudocapacitive materials, waste of space volume, low volume energy density and low power density, so as to improve volume energy density, avoid waste of pore space, and large The effect of specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare flexible thin film electrode materials, the specific steps are as follows:

[0038] 1) 0.2g vanadium pentoxide (V 2 o 5 ) and 0.45 g of oxalic acid dihydrate (H 2 C 2 o 4 2H 2 O) Add 10 ml of acetone (CH 3 COCH 3 ) and 25 milliliters of water, stirred with a water-bath magnetic stirrer at 40°C for 24 hours to obtain a uniform blue solution;

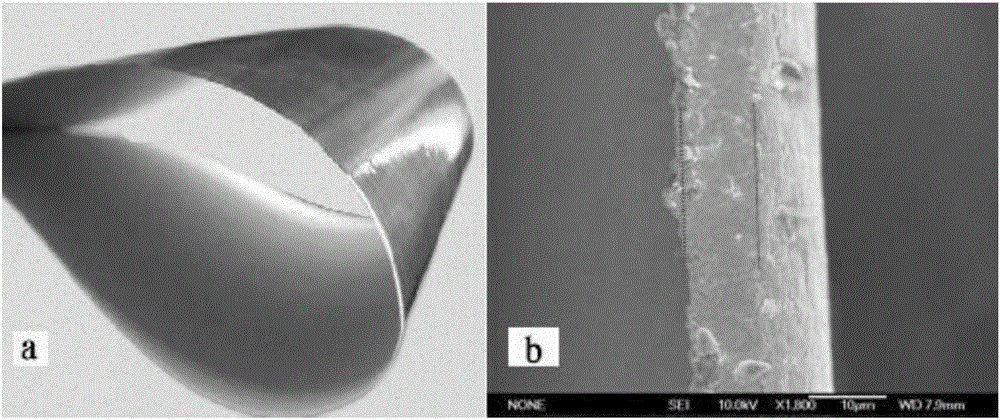

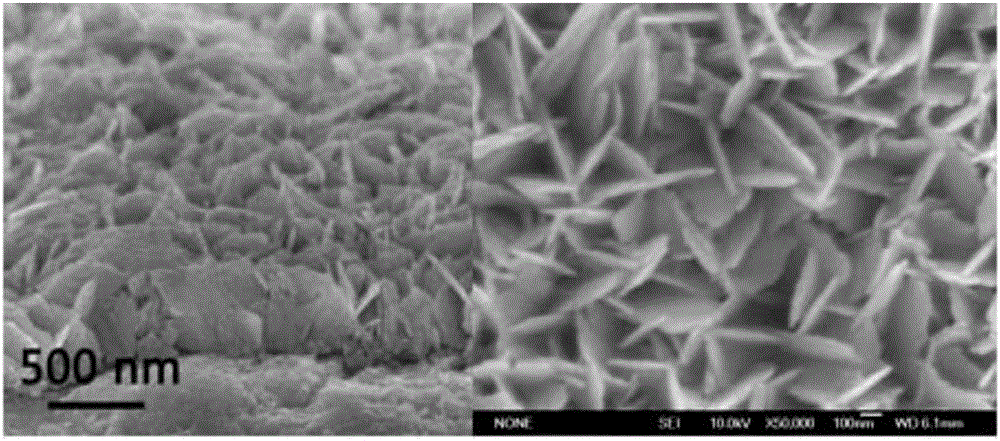

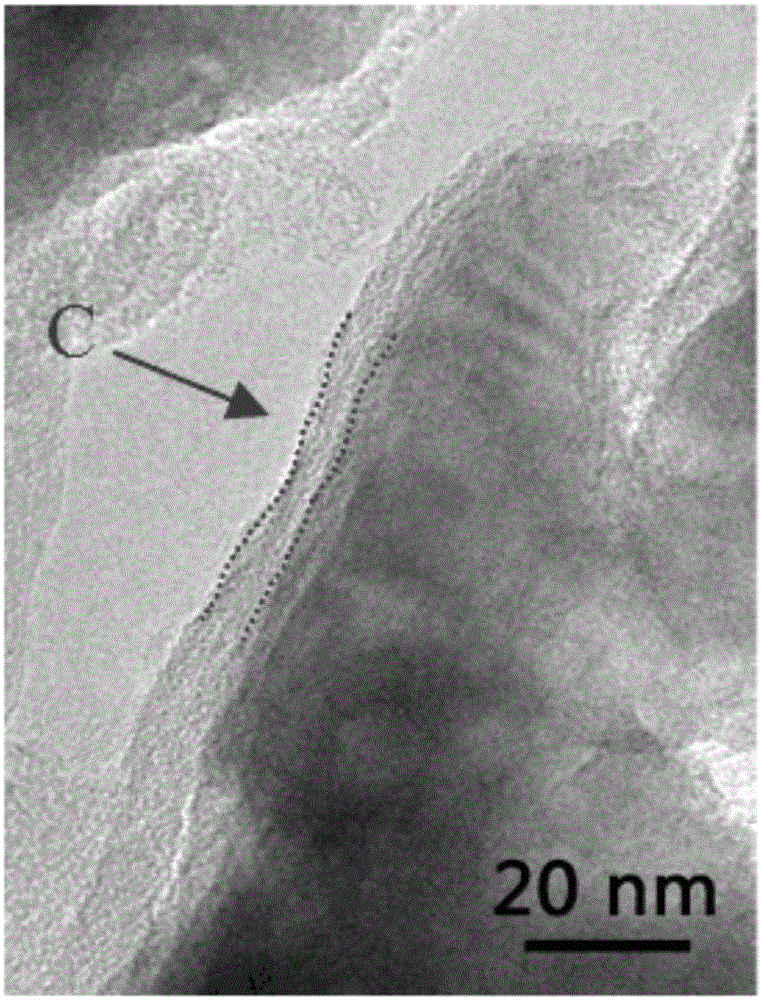

[0039] 2) The 10-micron ultra-thin titanium sheet is ultrasonically washed in hydrochloric acid and deionized water in sequence, dried, and one side is covered with a thick titanium sheet, and then placed in the water of the polytetrafluoroethylene liner substrate together with the above-mentioned stirred solution. In a thermal reaction kettle, conduct a hydrothermal reaction at 180°C for 18 hours to form a vanadium dioxide nanosheet array on the surface of the titanium sheet, then take out the titanium sheet with the nanosheet array, wash and dry it with deionized water, and place it on the titanium sheet Add (0.16...

Embodiment 2

[0044] To prepare an all-solid-state asymmetric flexible film supercapacitor, the specific steps are as follows:

[0045] Carbon-coated vanadium trioxide (V 2 o 3 C) Nanosheet arrays are used as positive and negative electrodes, and lithium chloride / polyvinyl alcohol (LiCl / PVA) gel is used as a quasi-solid electrolyte (the preparation method is: first prepare a 5mol / L lithium chloride solution, and then add polyvinyl alcohol powder , the mass ratio of polyvinyl alcohol powder to lithium chloride solution is 0.1g / mL, stirred in a water bath at 85°C for 2-3 hours, and left to cool to obtain), assembled into an all-solid asymmetric flexible film supercapacitor. Such as Figure 11 It is a scanning electron microscope image of the cross-section of the supercapacitor, in which the electrodes are fully in contact with the electrolyte, and the thickness of the entire device is about 40 microns.

[0046] The electrochemical performance of the supercapacitor was tested, Figure 12 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com