Inorganic and organic composite coagulant and preparation method and application thereof

A coagulant and organic technology, applied in the field of coagulant preparation, can solve the problems affecting the stability and performance of the composite coagulant, unsatisfactory treatment effect, large amount of sludge, etc., to avoid secondary metal Pollution, fast onset, fast clarification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment relates to the preparation of a group of inorganic-organic composite coagulants, using the following steps:

[0022] A, add dimethyl diallyl ammonium chloride into water according to a certain weight ratio, stir evenly, obtain dimethyl diallyl ammonium chloride solution;

[0023] B, add a certain amount of ferric chloride in the dimethyl diallyl ammonium chloride solution that step a obtains, continue to stir, obtain mixed solution;

[0024] c. Add an initiator to the mixed solution obtained in step b, stir and react at high temperature to obtain an inorganic-organic composite coagulant;

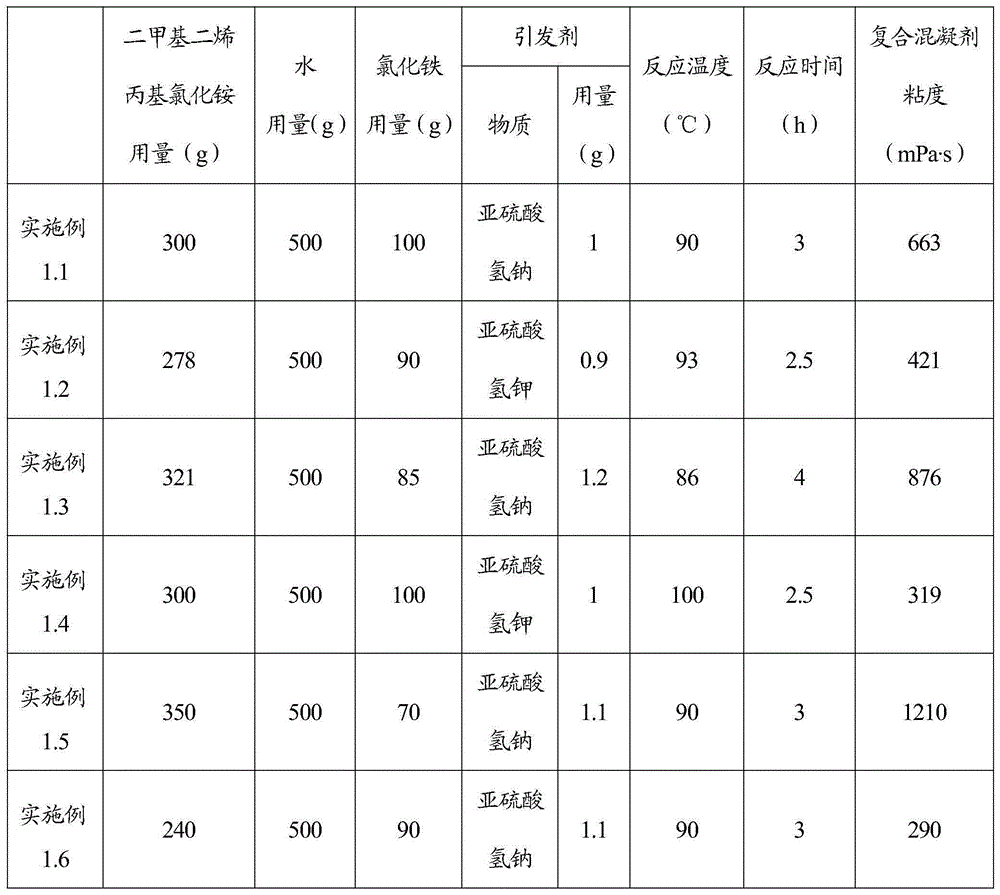

[0025] Each conditional parameter of above-mentioned preparation process is shown in the following table:

[0026]

[0027] Examples 1.1-1.3 are inorganic-organic composite coagulants obtained by the preparation method of the present invention, and Examples 1.4-1.6 are inorganic-organic composite coagulants whose preparation conditions are not within the scope of t...

Embodiment 2

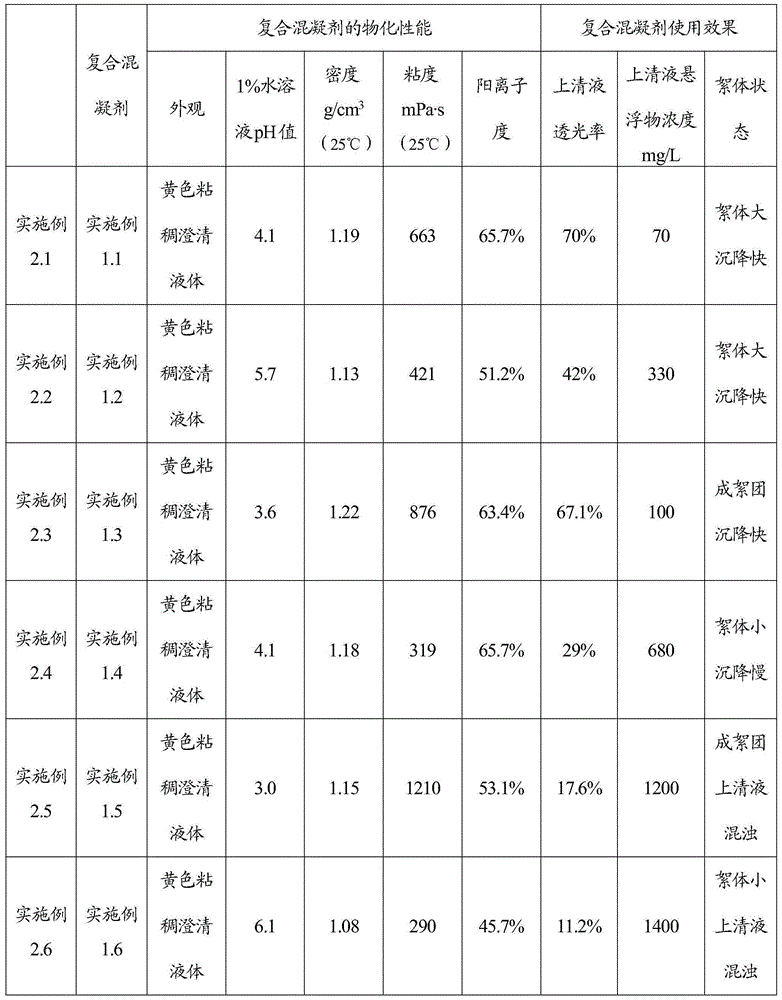

[0029] This example relates to the verification of the physical and chemical properties and application effects of the inorganic-organic composite coagulant prepared in Example 1.

[0030] The physical and chemical properties of the inorganic-organic composite coagulant are tested as follows: use a pH meter to measure the pH value of the 1% aqueous solution of the inorganic-organic composite coagulant; use a density meter and a viscometer to measure the density value of the inorganic-organic composite coagulant at 25°C and viscosity value; use the Clˉ content precipitation titration method in balance with the cation, and refer to the detection of Clˉ in GB / T15453-2008 to determine the cationic degree of the inorganic-organic composite coagulant.

[0031] The use effect of the inorganic-organic composite coagulant is evaluated by the flocculation and sedimentation experiment: a flocculation and sedimentation experiment is carried out on a vitamin C fermentation broth (its initia...

Embodiment 3

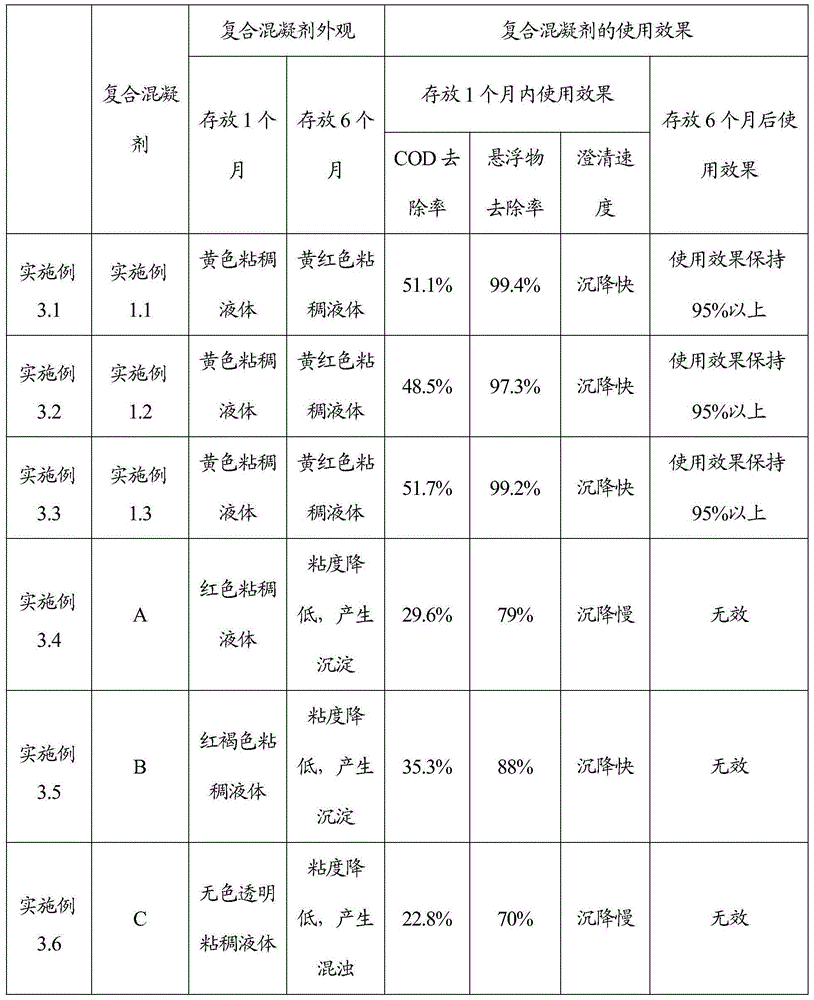

[0037] This embodiment relates to the inorganic-organic composite coagulant (A) obtained by compounding the inorganic-organic composite coagulant of Examples 1.1 to 1.3 with ferric chloride and polymerized dimethyl diallyl ammonium chloride homopolymer. Inorganic-organic composite coagulant (B) compounded with polyferric chloride and polydimethyldiallylammonium chloride homopolymer, and combined with conventionally used polyaluminum chloride and polyacrylamide (C) The comparative verification of the stable performance and the use effect for treating biopharmaceutical wastewater and fermentation wastewater, the effect experiment is the same as in Example 2, and the comparison of COD removal rate is increased, and the detection of COD adopts the national standard GB11914-1989 Water Quality_Chemical Requirements Oxygen Determination - Potassium Dichromate Method. The results are shown in the table below:

[0038]

[0039] It can be seen from the results in the above table tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com