A kind of blend film containing graphene and preparation method thereof

A technology of blended film and graphene, which is applied in the direction of semiconductor devices, photovoltaic power generation, electrical components, etc., can solve the problems of poor bonding performance, poor dispersion effect, and degradation of material mechanical properties, so as to reduce the degree of crystallization and eliminate melting. Bulk cracking phenomenon, film quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

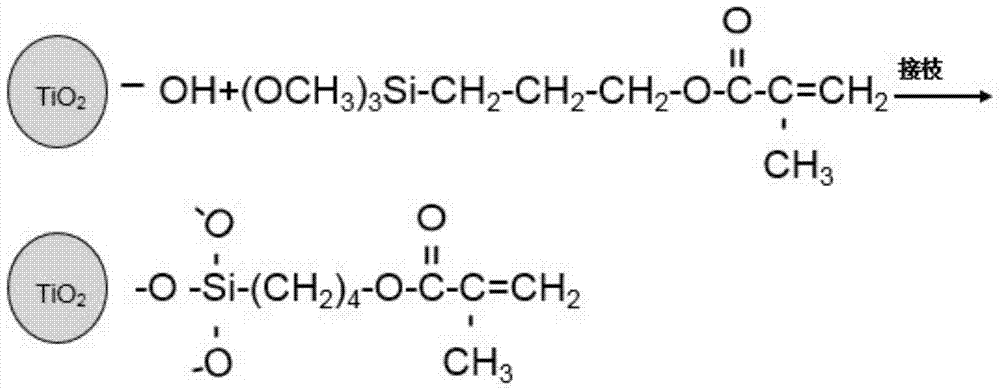

[0038] According to KH570: Nano titanium dioxide volume mass fraction ratio 15ml: 1g weighs the reactant, first puts the nano titanium dioxide powder in a vacuum drying oven at 50 degrees, places it for 12 hours to remove moisture, then dissolves it in absolute ethanol, then adds KH570 reagent, The obtained mixed solution was ultrasonically treated at a temperature of 50 degrees to evaporate ethanol, and then ground and stirred in a stirred reactor for 1 hour, and finally the obtained mixture was filtered with absolute ethanol and dried to obtain modified titanium dioxide powder.

[0039] Titanium dioxide graft, PVDF, PMMA, PPA and graphene are mixed according to the mass fraction of 4~8:55~65:35~45:4~8:3~4, the mixing method is mechanical stirring, and the stirring rate is 100 rpm, the time is 5 minutes, then the extruder extrudes and granulates, and the extrusion parameters are:

[0040] Table 1 Extruder granulation parameters

[0041] a district Second District ...

Embodiment 2

[0050] According to KH570: nano-titanium dioxide volume mass fraction ratio 5ml: 1g weighs the reactant, first puts the nano-titanium dioxide powder in a vacuum drying oven at 50 degrees, places it for 12 hours to remove moisture, then dissolves it in absolute ethanol, and then adds KH570 reagent, The obtained mixed solution was ultrasonically treated at a temperature of 50 degrees to evaporate ethanol, and then ground and stirred in a stirred reactor for 1 hour, and finally the obtained mixture was filtered with absolute ethanol and dried to obtain modified titanium dioxide powder.

[0051] Titanium dioxide grafts, PVDF, PMMA, PPA and graphene are mixed according to the mass fraction of 2~10:50~70:30~50:2~10:3~4, and the mixing method is mechanical stirring, and the stirring rate is 100 rpm, the time is 5 minutes, then the extruder extrudes and granulates, and the extrusion parameters are:

[0052] Table 3 Extruder granulation parameters

[0053] a district Secon...

Embodiment 3

[0058] Weigh the reactants by KH570: nanometer titanium dioxide volume mass fraction ratio 20ml: 1g, first place the nanometer titanium dioxide powder in a vacuum drying oven at 50 degrees, place it for 12 hours to remove moisture, then dissolve it in absolute ethanol, then add KH570 reagent, The obtained mixed solution was ultrasonically treated at a temperature of 50 degrees to evaporate ethanol, and then ground and stirred in a stirred reactor for 1 hour, and finally the obtained mixture was filtered with absolute ethanol and dried to obtain modified titanium dioxide powder.

[0059] Titanium dioxide graft, PVDF, PMMA, PPA and graphene are mixed according to the mass fraction of 2~10:50~70:30~50:4~8:2~5, the mixing method is mechanical stirring, and the stirring rate is 100 rpm, the time is 5 minutes, then the extruder extrudes and granulates, and the extrusion parameters are:

[0060] Table 5 Extruder granulation parameters

[0061] a district Second District ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com