Method for recovering zinc ions in willemite ore wastewater

A technology of zinc ions and ore, applied in the field of recovering zinc ions in willem ore wastewater, can solve the problems of low adsorption capacity, long adsorption time and high time cost, and achieve obvious economic benefits, high resin recovery rate and fast adsorption speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

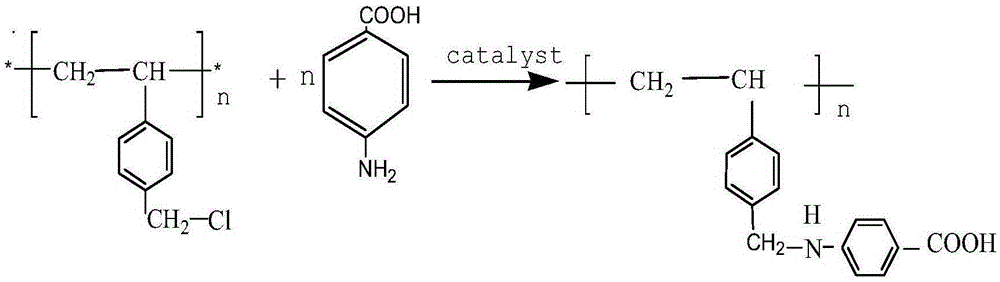

[0030] (1) Accurately weigh 60.0 mg of chlorine balls, transfer them into a 100 mL three-necked bottle, add 40 mL of N,N-dimethylformamide (DMF) as a reaction solvent, and soak until the chlorine balls are fully swollen. Among them, the chlorine balls Macroporous cross-linked chloromethylated polystyrene beads;

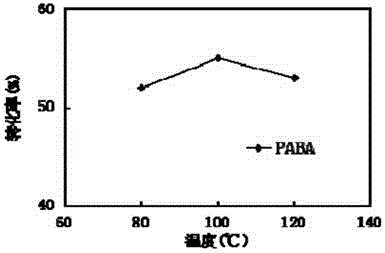

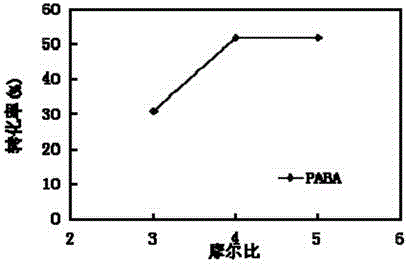

[0031] (2) Add p-aminobenzoic acid (PABA) as a ligand in the obtained product of step (1), the reaction molar ratio of chlorine balls and p-aminobenzoic acid is 1:4, add catalyst, at 80 ℃ of reaction temperature Under nitrogen protection, the stirring reaction was carried out for 10 hours, and the rotating speed was 200r / min;

[0032] (3) After the reaction, filter the product of step (2) to obtain a filter cake, soak and wash the filter cake with N,N-dimethylformamide as the reaction solvent until the washing liquid is colorless, and then wash with distilled water , then soaked in NaOH aqueous solution, washed with water, then washed with absolute ethanol, acetone, ...

Embodiment 2

[0049] Experiment 1

[0050] Take by weighing 7 parts of 15.0mg synthetic resins obtained by the present invention and place them in iodine measuring bottles respectively, then add pH=3, pH=3.5, pH=4.0, pH=4.5, pH=5, pH= 5.5 and 25 mL of acetic acid-sodium acetate buffer solution with pH=6 were soaked in an iodine bottle for 24 hours, and then, an appropriate amount of prepared silicon-zinc ore wastewater was taken to make Zn 2+The concentration is 2mg / ml, then take 5mL of the solution, shake it at a constant temperature for 10 hours under the conditions of r=200r / min, T=298K, and measure the saturated adsorption capacity of the synthetic resin for metal zinc ions after the adsorption equilibrium.

[0051] Among them, the adsorption capacity (q e ) and distribution ratio (D):

[0052] q e = ( C 0 - C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com