High-temperature corrosion-resistant distillation seawater desalination system and method based on waste heat utilization of flue gas

A flue gas waste heat and corrosion-resistant technology, applied in chemical instruments and methods, seawater treatment, water/sewage multi-stage treatment, etc. Drops and other problems, to achieve the effect of high water production ratio, wide operating temperature range, and increase water production ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

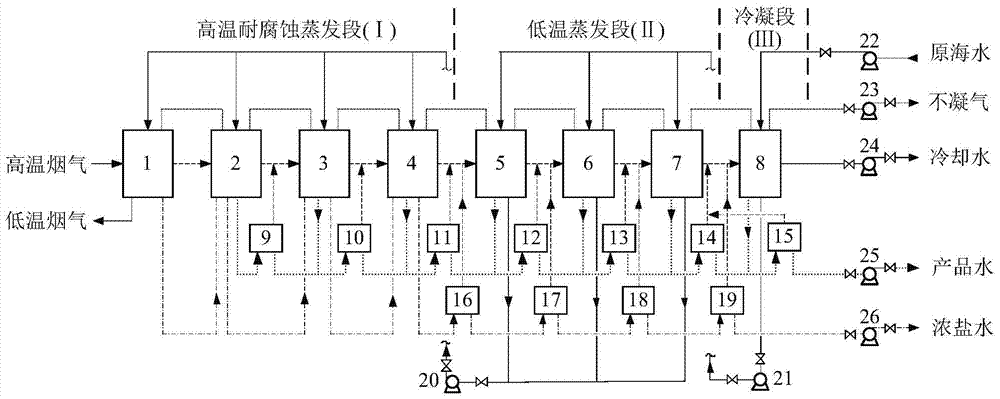

[0027] High-temperature corrosion-resistant distillation seawater desalination system based on flue gas waste heat utilization, see figure 1, including high-temperature corrosion-resistant evaporation section I, low-temperature evaporation section II, condenser 8, product water flash tank, product water balance tank 15, concentrated brine flash tank, concentrated brine balance tank 19, effect pump 20, feed pump 21. Raw material water pump 22, vacuum pump 23, cooling water pump 24, product water pump 25 and concentrated brine pump 26; high temperature corrosion resistant evaporation section I includes N high temperature corrosion resistant evaporators, N=4, respectively 1, 2, 3 , shown in 4; the low-temperature evaporation section II includes M low-temperature evaporators, M=3, shown in 5, 6, and 7 respectively; the product water flash tank is (N-1+M), respectively represented by 9, Shown in 10, 11, 12, 13, 14; concentrated brine flash tanks are M, respectively shown in 16, 17,...

Embodiment 2

[0031] The high-temperature corrosion-resistant distillation seawater desalination method based on the utilization of flue gas waste heat includes the following steps:

[0032] 1) Use the high-temperature corrosion-resistant distillation seawater desalination system based on the utilization of flue gas waste heat in Example 1;

[0033] 2) The raw seawater is preheated in the condenser 8 through the raw water pump 22;

[0034] 3) Part of the preheated raw seawater is discharged through the cooling water pump, and the other part is used as feed seawater to enter the low-temperature evaporators of the low-temperature evaporation section through the feed pump 21 to evaporate;

[0035] 4) Collect the remaining concentrated brine from each effect low-temperature evaporator in the low-temperature evaporation section and inject it into each effect high-temperature corrosion-resistant evaporator in the high-temperature corrosion-resistant evaporation section through the effect pump 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com