Preparation method of carbon nano tube reinforced conducting polymer hydrogel

A technology of conductive polymers and carbon nanotubes, which is applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problems of small effective specific surface area of composite materials, and achieve the effects of easy scale-up production, simple equipment, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

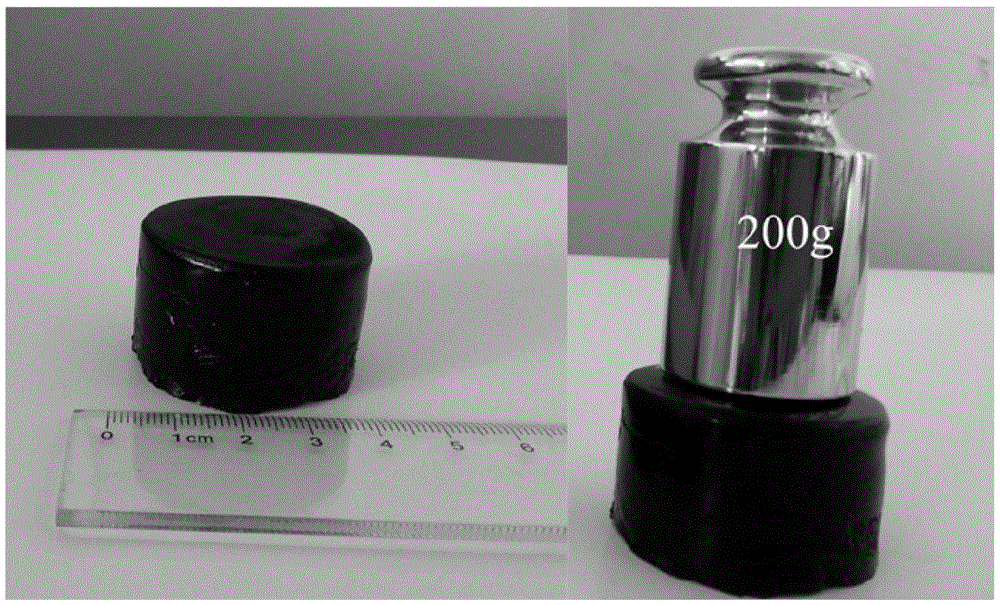

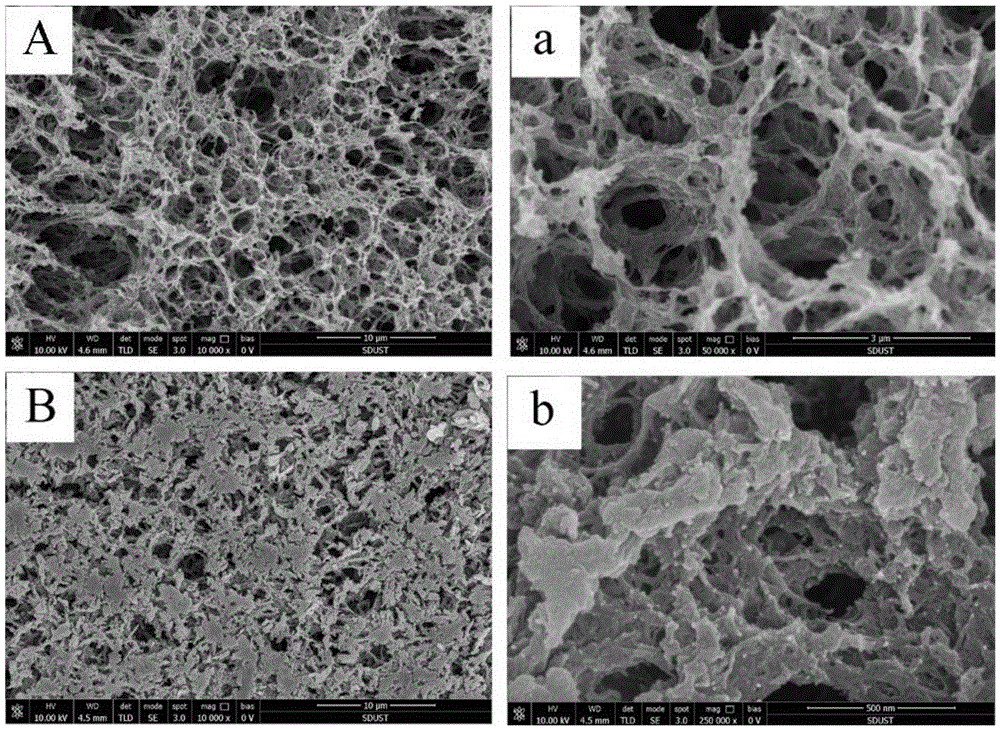

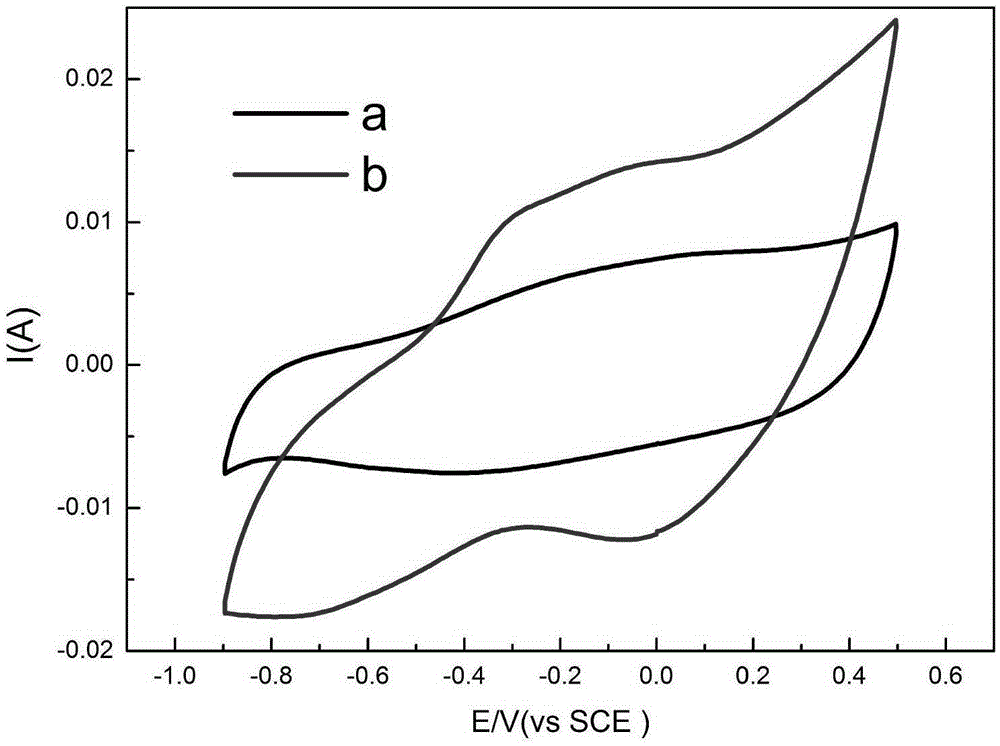

[0029] A preparation method of carbon nanotube reinforced conductive polymer hydrogel, the steps are as follows:

[0030] (1) At room temperature, add 0.3348 g (1.5 mmol) (5 mM) of 1-aminoanthraquinone (purchased from Sinopharm Chemical Reagent Co., Ltd.) into 300 mL of ethanol, and stir to form a solution.

[0031] (2) At room temperature, 0.3g (1g / L) epoxidized carbon nanotubes (see Ogrin, D., Chattopadhyay, J, Sadana, A.K, Billups, W.E, Barron, A.R. Epoxidation and deoxygenation of single-walled carbon nanotubes: Quantification of epoxide defects. JAmChemSoc, 2006, 128, 11322-11323.) was dissolved in the above solution, stirred and dispersed by ultrasonic waves to form a dispersion liquid, and prepared electroactive molecule-grafted carbon nanotubes by reflux reaction. The reflux reaction temperature was 90°C and the reaction time was 12h.

[0032] (3) 0.824 g (4 mmol) (0.2 M) of polystyrene sulfonate (purchased from Suzhou Bohong Chemical Technology Co., Ltd.) was dissolv...

Embodiment 2

[0044] A preparation method of electroactive molecule grafted carbon nanotube reinforced conductive polymer hydrogel, which differs from Example 1 in that 0.3348g (1.5mmol) 1-aminoanthraquinone becomes 0.6696g (3mmol) 2- Aminoanthraquinone, the quality of epoxidized carbon nanotubes becomes 0.5g, the quality of sodium polystyrene sulfonate becomes 0.412g (2mmol) the quality of electroactive molecule grafted carbon nanotubes becomes 1mg (0.05mg / mL ), 880μL (8mmol) 3,4-ethylenedioxythiophene monomer becomes 90μL (1mmol) aniline monomer, 15.35gFe(NO 3 ) 3 9H 2 O (38mmol) becomes 1.622g (10mmol) anhydrous ferric trichloride, standing reaction 24h becomes 12h, purification equilibrium time becomes 3 days from 5 days.

Embodiment 3

[0046] A preparation method of electroactive molecule grafted carbon nanotube reinforced conductive polymer hydrogel, which differs from Example 1 in that 0.3348g (1.5mmol) 1-aminoanthraquinone becomes 1.1912g (5mmol) 1, 4-diaminoanthraquinone, the quality of epoxidized carbon nanotubes becomes 1g, the reflux reaction time becomes 24h, the quality of sodium polystyrene sulfonate becomes 2.06g (10mmol), and electroactive molecules graft carbon nanotubes The quality of the mass becomes 5mg (0.25mg / mL), 880μL (8mmol) 3,4-ethylenedioxythiophene monomer becomes 280μL (4mmol) pyrrole monomer, 15.35gFe(NO 3 ) 3 9H 2 O (38mmol) became 6.6g (30mmol) cerium ammonium nitrate, and the static reaction changed from 24h to 18h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole size | aaaaa | aaaaa |

| Hole size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com