swsr‑6 Sulfur recovery process and device

A sulfur recovery and process technology, which is applied in the preparation/purification of sulfur, the preparation of alkali metal sulfites, etc., can solve the problems that the sulfur recovery effect cannot meet the environmental protection requirements, the high requirements for device safety control, and the high energy consumption of the device, and achieves The effect of saving land, convenient operation and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

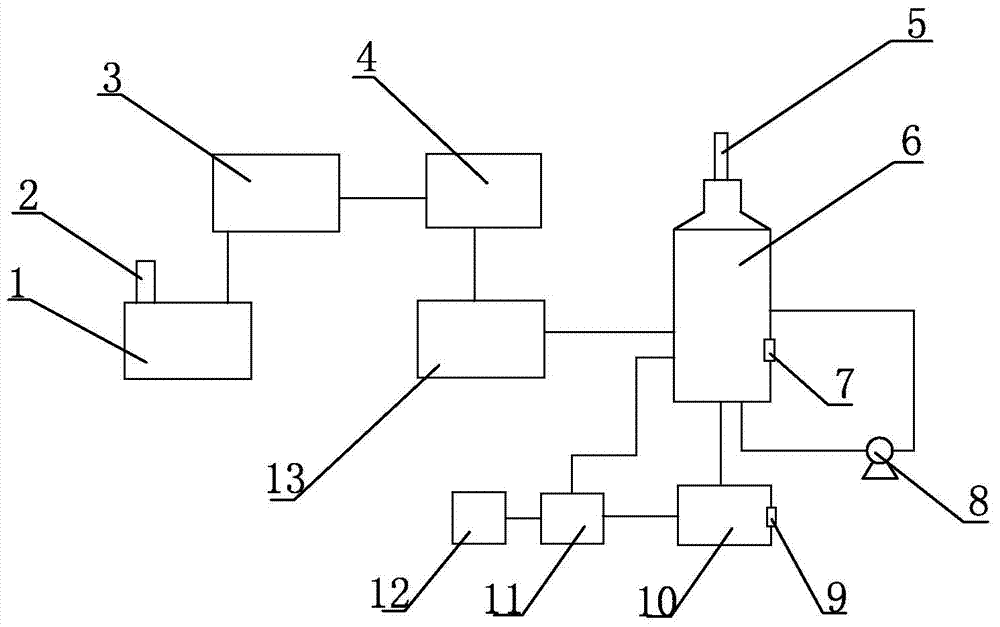

[0065] A SWSR-6 sulfur recovery device, comprising a sulfur production combustion furnace 1, a Claus reaction system 3, a tail gas incineration system 13 and a flue gas purification tower 6 connected in sequence through pipelines, and the sulfur production combustion furnace 1 is equipped with a hydrogen sulfide-containing Acid gas inlet 2, the top of the flue gas purification tower 6 is provided with a purified flue gas outlet 5, the outlet at the bottom of the flue gas purification tower 6 is connected to the inlet of the side of the flue gas purification tower 6 through a pipeline, and the pipeline is provided with a circulation pump 8 at the bottom of the purification tower, One side of the flue gas purification tower 6 is also provided with a first sodium hydroxide inlet 7, and the bottom of the flue gas purification tower 6 is connected to a neutralization tank 10 through a pipeline, and a second sodium hydroxide inlet 9 is arranged on the neutralization tank 10, and the n...

Embodiment 2

[0080] The SWSR-6 sulfur recovery process used in Example 2 and the SWSR-6 sulfur recovery device are the same as in Example 1, the only difference being that step ④ in the SWSR-6 sulfur recovery process is the liquid evaporated in the equilibrium absorption process, and the smoke In the gas purification tower 6, process water needs to be supplemented to keep the liquid phase liquid level in the flue gas purification tower at 80%; add sodium hydroxide to the flue gas purification tower 6 through the first sodium hydroxide inlet 7, so that the flue gas purification tower The pH value in 6 is controlled at 7, and sodium hydroxide is added to the neutralization tank 10 through the second sodium hydroxide inlet 9, and the pH value in the neutralization tank 10 is controlled at 8.

[0081] Example 2 The sulfur production process produces sulfur products that meet the requirements of GB / T2449, and the desulfurization process produces anhydrous sodium sulfite products that meet GB1894...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com