A kind of preparation method of continuous oxide fiber fabric surface coating

A surface coating and fiber fabric technology, applied in the field of preparation of continuous oxide fiber fabric surface coating, can solve the problem that the interface between pyrolytic carbon and BN cannot meet the requirements of anti-oxidation, long life and high reliability, and harsh service conditions, etc. problems, to achieve the effect of short preparation cycle, low equipment requirements, and improved strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

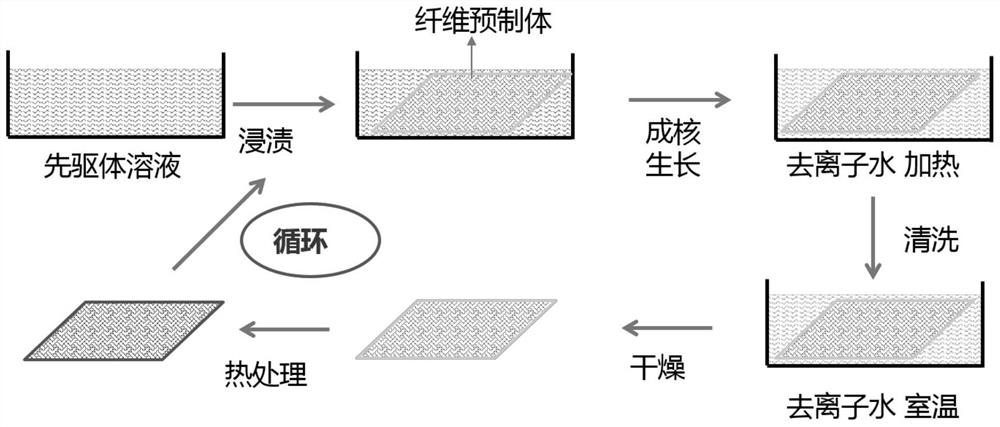

[0027] (12) Preparation of coating phase precursor

[0028] Prepare the coating precursor solution by stirring and mixing the solution. The precursor solution is one or more of the following mixed solutions, nitrate and phytic acid mixed solution, nitrate and phosphoric acid, citric acid mixed solution, nitrate and phosphoric acid Ammonium dihydrogen mixed solution, the concentration of nitrate in the coating precursor solution is 30-80%;

[0029] (13) Continuous oxide fiber preform impregnation process

[0030] Immerse the pretreated continuous oxide fiber preform in the above precursor solution for 10-20s, take it out, put it in deionized water at 50-100°C, and keep stirring for 5-15min, rinse the fiber cloth with deionized water after taking it out surface to remove ions in solution and loose solids on the surface;

[0031] (14) Coating drying and heat treatment process

[0032] The fiber preform impregnated with the precursor solution is put into an oven to dry, and the...

Embodiment 1

[0036] Put the 610 alumina fiber fabric of 3M company in a muffle furnace for heat treatment at 800°C for 1 hour, and remove the surface sizing agent before use.

[0037] Stir and mix lanthanum nitrate (La(NO3)3·6H2O) and phytic acid (pc) in a deionized medium to prepare a precursor solution, wherein the concentration of lanthanum nitrate is 50%. Then, immerse the alumina fiber fabric in the precursor solution for 15 seconds, take it out, put it in deionized water at 90°C, and keep stirring for 5 minutes, so that LaPO4 is deposited on the surface of the fiber cloth, and rinse the coating with deionized water after taking it out. 20s on the surface of the fiber cloth to remove ions in the solution and loose solids on the surface. Then arrange the fibers in an oven and dry at 120°C for 15 minutes, then put them into a muffle furnace, heat-treat at 800°C for 5 minutes, and then take them out directly, so that the impregnation-heat treatment cycle is repeated 6 times, and finally ...

Embodiment 2

[0039] After soaking the mullite fiber fabric produced by Mitsubishi Corporation in acetone for 30 minutes, place it in a muffle furnace for heat treatment at 500°C for 2 hours, remove the surface sizing agent, and set it aside for use.

[0040] The precursor solution was prepared by magnetic stirring and mixing neodymium nitrate (Nd(NO3)3·6H2O) and ammonium dihydrogen phosphate (ADPH) in a deionization medium, wherein the concentration of lanthanum nitrate was 60%. Then, immerse the alumina fiber fabric in the precursor solution for 10 seconds, take it out, put it in deionized water at 80°C, and keep stirring for 8 minutes, so that NdPO4 is deposited on the surface of the fiber cloth, and rinse the coated surface with deionized water after taking it out. 15s on the surface of the fiber cloth to remove ions in the solution and loose solids on the surface. Then arrange the fibers in an oven and dry at 100°C for 20 minutes, then put them into a muffle furnace, heat-treat at 900°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com