Electronic heat-resisting composite material

A composite material and electronic heat-resistant technology, applied in the field of electronic materials, can solve the problems of poor weather resistance and heat and humidity resistance, difficulty in meeting engineering technology, high cross-linking density, etc., and achieve good mechanical properties, good curing effect, and compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Mix 350g of silicon dioxide, 20g of ytterbium fluoride, 160g of boron oxide, 190g of rutile titanium dioxide, 100g of zirconia, and 180g of shell powder, and then pass through a 500-mesh standard sieve to obtain a mixed powder; put the mixed powder at 650 Calcining at ℃ for 1 hour; then smelting the mixed powder at 1580℃ for 3 hours, quenching to obtain a glass block; finally, ball milling the glass block for 5 hours, and passing through a 800-mesh standard sieve to obtain ceramic powder;

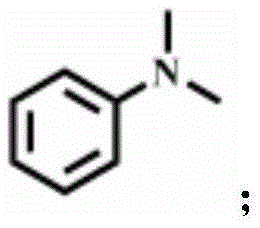

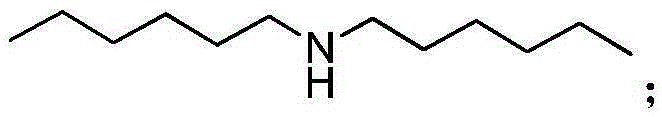

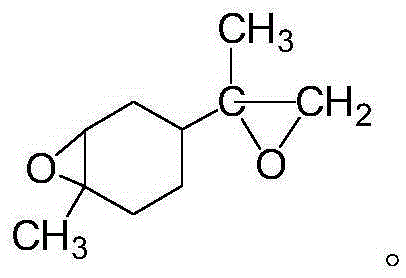

[0044] 2. Mix 6g of nitrogen compound and 10.5g of ceramic powder for 2 hours, then add 1.3g of N-formylmorpholine and 1.8g of sodium iodide, and mix for 1.5 hours to obtain a mixture; sequentially mix 9g of amine compound, 28g of diisoprene Epoxide was added to the mixture and stirred at 95°C for 2 hours; then 11 g of acrylate-styrene copolymer was added and stirred at 120°C for 1 hour; then 6 g of 2,6-bis(4-aminophenoxy)benzonitrile was added , stirred at 180°C for 2 minutes to ...

Embodiment 2

[0046] 1. Mix 350g of silicon dioxide, 20g of ytterbium fluoride, 160g of boron oxide, 190g of rutile titanium dioxide, 100g of zirconia, and 180g of shell powder, and then pass through a 500-mesh standard sieve to obtain a mixed powder; put the mixed powder at 650 Calcining at ℃ for 1 hour; then smelting the mixed powder at 1580℃ for 3 hours, quenching to obtain a glass block; finally, ball milling the glass block for 5 hours, and passing through a 800-mesh standard sieve to obtain ceramic powder;

[0047] 2. Mix 80g of nitrogen compound and 100g of ceramic powder for 2 hours, then add 12g of N-formylmorpholine and 20g of sodium iodide, and mix for 1.5 hours to obtain a mixture; sequentially mix 95g of amine compound and 250g of diisoprene diepoxide Add to the mixture, stir at 95°C for 2 hours; then add 120g acrylate-styrene copolymer, stir at 120°C for 1 hour; then add 80g2,6-bis(4-aminophenoxy)benzonitrile, at 180 Stir at ℃ for 2 minutes to obtain the composite; then put th...

Embodiment 3

[0049] 1. Mix 350g of silicon dioxide, 20g of ytterbium fluoride, 160g of boron oxide, 190g of rutile titanium dioxide, 100g of zirconia, and 180g of shell powder, and then pass through a 500-mesh standard sieve to obtain a mixed powder; put the mixed powder at 650 Calcining at ℃ for 1 hour; then smelting the mixed powder at 1580℃ for 3 hours, quenching to obtain a glass block; finally, ball milling the glass block for 5 hours, and passing through a 800-mesh standard sieve to obtain ceramic powder;

[0050]2. Mix 7g of nitrogen compound and 10.5g of ceramic powder for 2 hours, then add 1.2g of N-formylmorpholine and 1.9g of sodium iodide, and mix for 1.5 hours to obtain a mixture; sequentially mix 9g of amine compound and 26.5g of diisoprene Diepoxide was added to the mixture and stirred at 95°C for 2 hours; then 11g of acrylate-styrene copolymer was added and stirred at 120°C for 1 hour; then 7g of 2,6-bis(4-aminophenoxy)benzyl was added Nitrile, stirred at 180°C for 2 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com