4h-sic ultraviolet photodetector with double working mode and preparation method thereof

A double-working mode, electrical detector technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of low UV/visible suppression ratio, high doping concentration of multiplication layer, high avalanche breakdown voltage, etc., and achieve high UV / Visible suppression ratio, low avalanche breakdown voltage, low dark current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

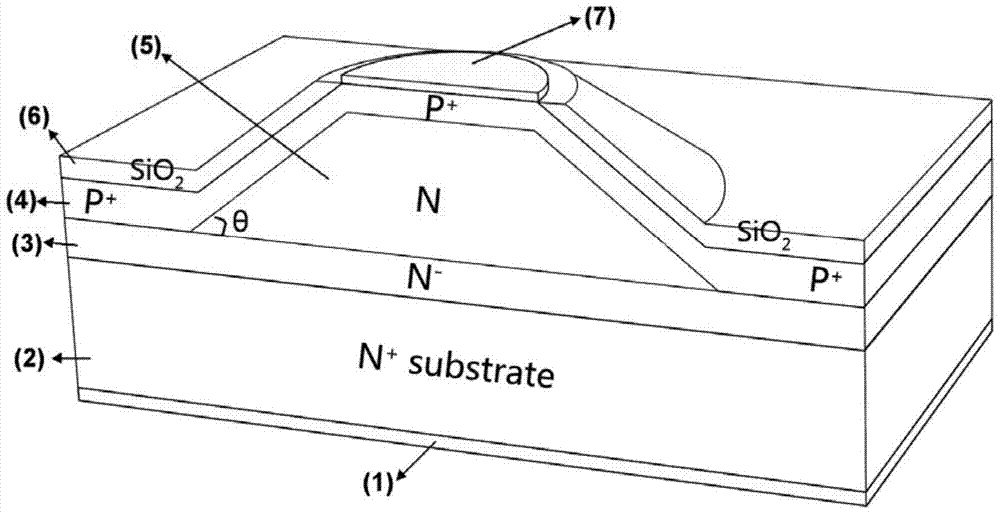

[0032] Such as figure 1 As shown, the 4H-SiC ultraviolet photodetector embodiment of the double working mode of the present invention is provided with N + Type 4H-SiC substrate 2, in N + Type 4H-SiC substrate 2 is sequentially provided with first N - Type epitaxial absorption layer 3 and the second N-type epitaxial multiplication layer 5; from the second N-type epitaxial multiplication layer 5 to the first N - The surface of the epitaxial absorption layer 3 is etched to a height so that the second N-type epitaxial multiplication layer 5 is a cone; - P + type ohmic contact layer, forming a P + N and P + N - Two PN junctions; at P + A silicon dioxide layer is grown on the surface of the type ohmic contact layer as the passivation layer of the device; a P-type electrode window is arranged on the passivation layer, and a P-type electrode window and an N + Type 4H-SiC substrate 2 is sputtered on the back of P electrode and N electrode respectively.

[0033] The first N - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com