SCR denitration catalyst and preparation method thereof

A technology of SCR catalyst and denitration catalyst, which is applied in the field of SCR denitration catalyst and its preparation in glass furnaces, can solve the problems that have not been considered, and achieve the effects of ensuring activity, smooth surface and reducing the probability of poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

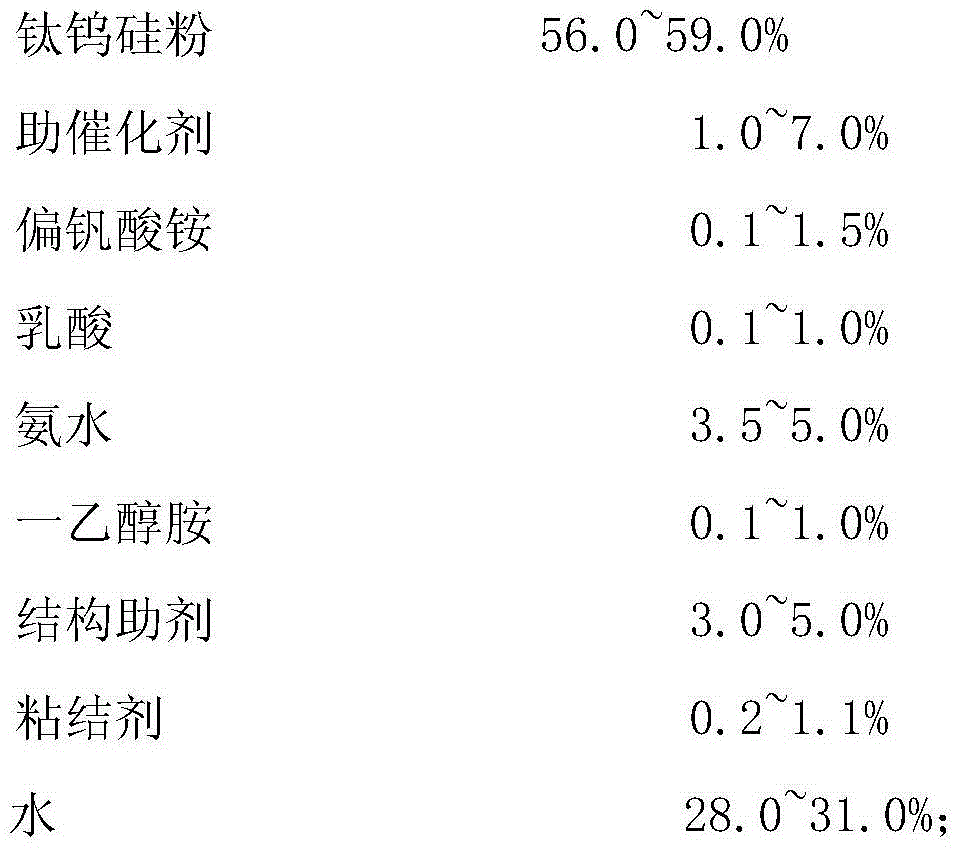

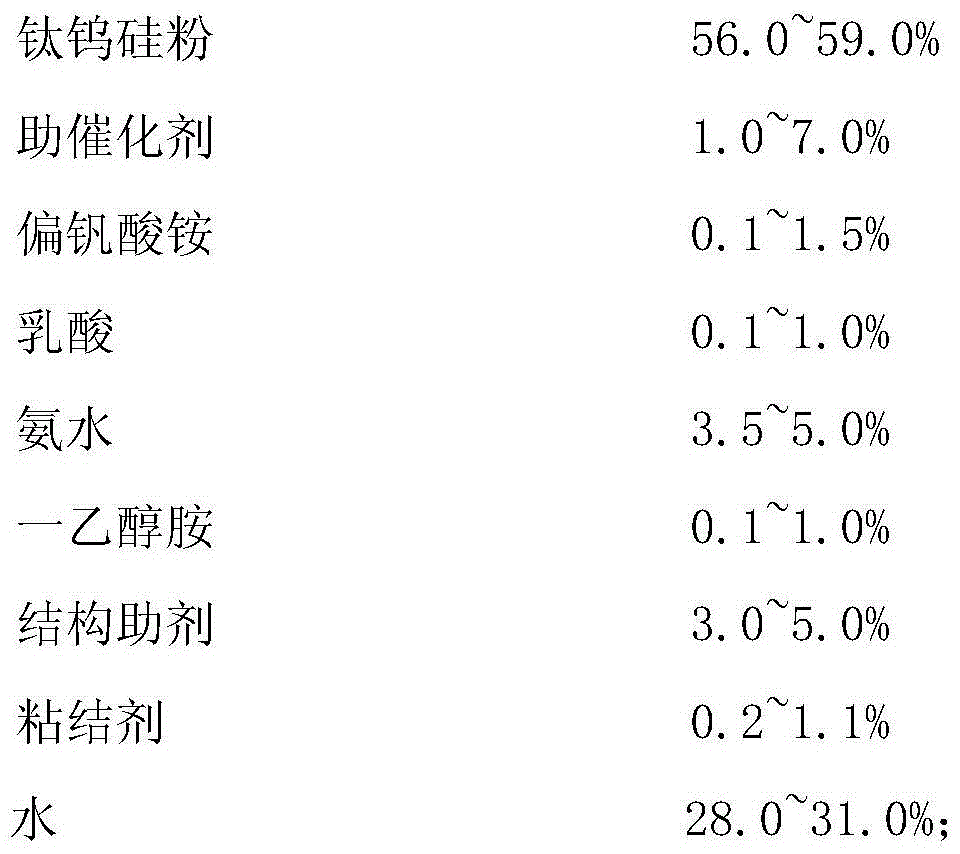

Embodiment 1

[0028] 1) Mixing. Weigh 613.76kg of titanium tungsten silicon powder, 13.7kg of cerium oxide, 5.48kg of molybdenum trioxide, 13.7kg of iron oxide, 5.48kg of copper oxide, 10.96kg of lanthanum oxide, 1.096kg of ammonium metavanadate, 6.028kg of L-type lactic acid, ammonia water 38.36kg, monoethanolamine 1.096kg, glass fiber 41.648kg, pulp cotton 4.932kg, stearic acid 1.096kg, carboxymethylcellulose sodium 3.836kg, polyethylene oxide 3.288kg, deionized water 306.88kg, in the mixer Mix evenly according to the steps to obtain a paste-like blank.

[0029] 2) Kneading the above-mentioned paste-like blank, staleing once, pre-extruding by filtration, staling twice, extruding by vacuum forming, drying once, drying twice, calcining, cutting, and assembling to obtain the glass furnace kiln SCR denitrification catalyst finished product.

[0030] Catalyst activity test: Cut a 75×75×150mm catalyst and put it into the activity evaluation device for activity test. The simulated flue gas is ...

Embodiment 2

[0033] 1) Mixing. Weigh 630kg of titanium tungsten silicon powder, 5.48kg of cerium oxide, 0kg of molybdenum trioxide, 21.92kg of iron oxide, 0kg of copper oxide, 10.96kg of lanthanum oxide, 8.768kg of ammonium metavanadate, 6.028kg of L-type lactic acid, 46.58kg of ammonia water, Monoethanolamine 6.028kg, glass fiber 41.648kg, pulp cotton 2.192kg, stearic acid 5.48kg, sodium carboxymethyl cellulose 6.576kg, polyethylene oxide 5.48kg, deionized water 323.32kg, mixed in the mixer step by step Evenly, a paste-like billet is obtained.

[0034] 2) Kneading the above dough paste, staleing once, filtering pre-extrusion, staleing the second time, vacuum forming extrusion, drying once, drying twice, calcining, cutting, and assembling to obtain the glass kiln The finished SCR denitrification catalyst.

[0035] Catalyst activity test: Cut a 75×75×150mm catalyst and put it into the activity evaluation device for activity test. The simulated flue gas is fed by N 2 , O 2 , NO, NH 3 、H...

Embodiment 3

[0038] 1) Mixing. Weigh 646.64kg of titanium tungsten silicon powder, 13.7kg of cerium oxide, 5.48kg of molybdenum trioxide, 5.48kg of iron oxide, 5.48kg of copper oxide, 0kg of lanthanum oxide, 1.096kg of ammonium metavanadate, 10.96kg of L-type lactic acid, 38.36kg of ammonia water kg, monoethanolamine 6.028kg, glass fiber 41.648kg, pulp cotton 7.672kg, stearic acid 1.096kg, carboxymethylcellulose sodium 1.096kg, polyethylene oxide 1.096kg, deionized water 339.76kg, press Step Mix evenly to obtain a paste-like blank.

[0039] 2) Kneading the above dough paste, staleing once, filtering pre-extrusion, staleing the second time, vacuum forming extrusion, drying once, drying twice, calcining, cutting, and assembling to obtain the glass kiln The finished SCR denitrification catalyst.

[0040] Catalyst activity test: Cut a 75×75×150mm catalyst and put it into the activity evaluation device for activity test. The simulated flue gas is fed by N 2 , O 2 , NO, NH 3 、H 2 O and SO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com