Catalyst for catalyzing hydrogenation of petroleum resin as well as preparation method and application thereof

The technology of petroleum resin and catalytic resin is applied in the field of preparation of nano metal catalysts, which can solve the problems of poor sulfur resistance, large water consumption, and large amount of waste liquid, and achieve the effects of simplifying production process operation, reducing economic cost and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

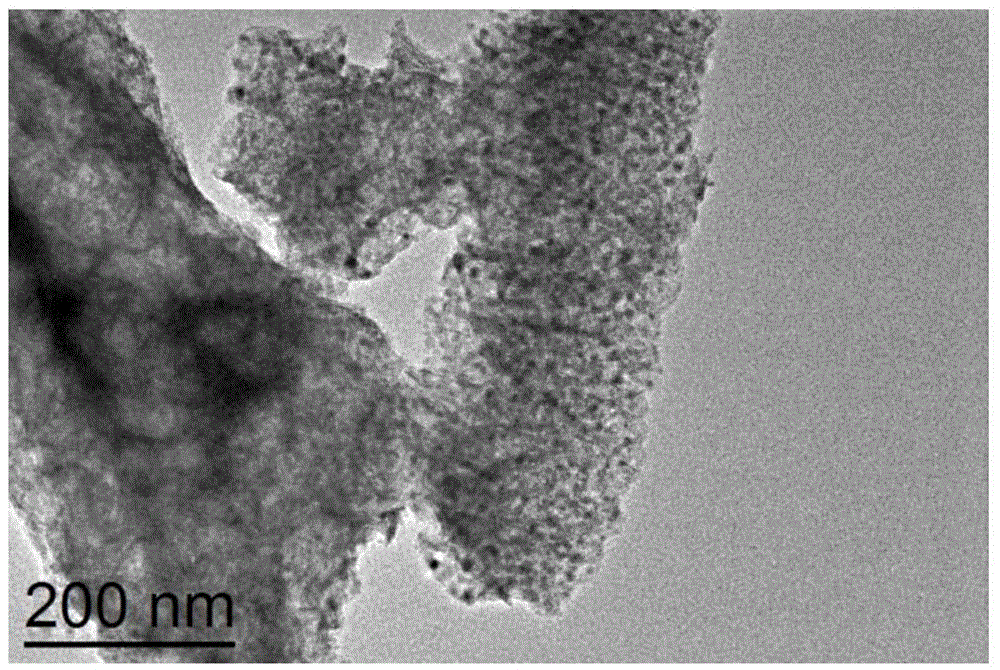

[0030] Preparation of Ni / MgO catalyst: 20 g of nickel acetate was dissolved in 180 mL of distilled water to prepare a 10% nickel acetate aqueous solution. Then, 27g of high-purity magnesium oxide powder was added into the above aqueous solution of nickel acetate under the condition of stirring at 25°C, and stirred for 18 hours. Prepare an ammonia solution with a mass concentration of 15%, add 20mL to the above mixture, and age at 85°C for 20h, filter, wash, and dry at 110°C. After reduction in hydrogen at 500°C for 8 hours, a nickel-supported magnesia catalyst can be obtained, and its transmission electron microscope photo is shown in figure 1 .

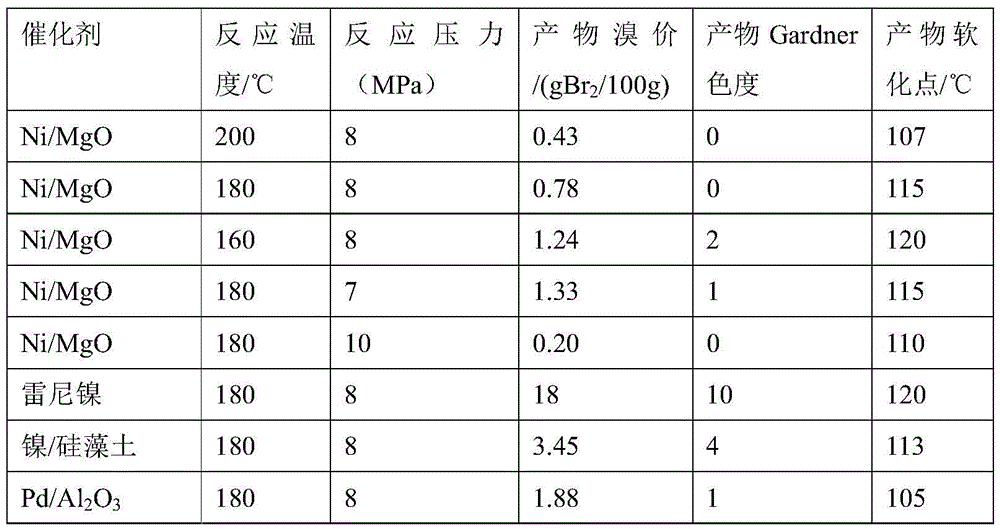

[0031] Catalyst performance test: A tank reactor was used to apply the catalyst to C9 resin hydrogenation. The reaction conditions were: 10g raw material, 50g cyclohexane solvent, 0.3g catalyst, and react for 5h. The result of the reaction is as follows:

[0032] Table 2. Hydrogenation results of C9 petroleum resin

[0033]

...

Embodiment 2

[0037] Preparation of Ni / MgO catalyst: 20 g of nickel acetate was dissolved in 180 mL of deionized water to prepare a 10% nickel acetate aqueous solution. Then, 27g of high-purity magnesium oxide powder was added into the above aqueous solution of nickel acetate under the condition of stirring at 25°C, and stirred for 18 hours. Prepare a sodium hydroxide solution with a mass concentration of 20%, add 27mL to the above mixture, age at 85°C for 20h, filter, wash, and dry at 110°C. After reduction in hydrogen at 500°C for 8 hours, a nickel-supported magnesium oxide catalyst can be obtained.

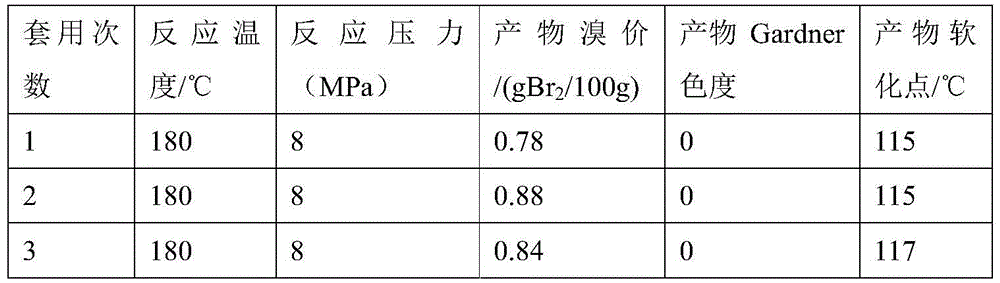

[0038]Catalyst performance test: A tank reactor was used to apply the catalyst to C9 resin hydrogenation. The reaction conditions were: 30g raw material, 180g petroleum ether, 2gNi / MgO catalyst, and react for 5h. The result of the reaction is as follows:

[0039] Table 4. Hydrogenation results of C9 petroleum resin

[0040]

Embodiment 3

[0042] Preparation of Ni / MgO catalyst: 20 g of nickel nitrate was dissolved in 180 mL of deionized water to prepare a 10% nickel nitrate aqueous solution. Then, 26 g of high-purity magnesium oxide powder was added into the above-mentioned nickel nitrate aqueous solution under the condition of stirring at 25° C., and stirred for 18 hours. Prepare an ammonia solution with a mass concentration of 15%, add 20mL to the above mixture, and age at 85°C for 20h, filter, wash, and dry at 110°C. After reduction in hydrogen at 500°C for 8 hours, a nickel-supported magnesium oxide catalyst can be obtained. Catalyst performance test: A tank reactor was used to apply the catalyst to the hydrogenation of C9 petroleum resin and C5 petroleum resin. The reaction conditions were: 10g raw material, 50g cyclohexane solvent, 0.3gNi / MgO catalyst, and react for 5h. The result of the reaction is as follows:

[0043] Table 5. Hydrogenation results of C9 petroleum resin

[0044]

[0045] Table 6. H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com