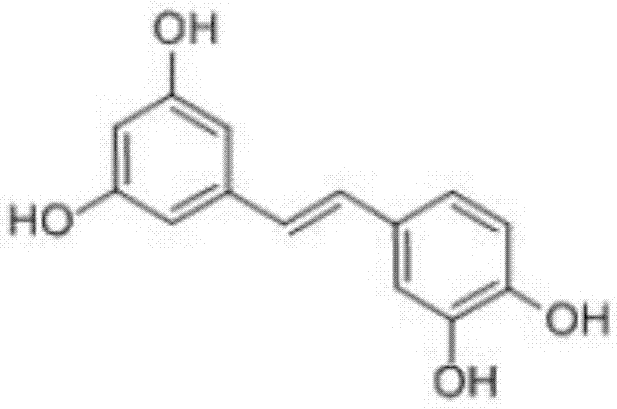

Synthesis method of piceatannol

A technology of picetanol and synthetic method, which is applied in the field of chemical synthesis of natural product piceatanl, can solve the problems of low reaction temperature, difficult handling, high price, etc., and achieve high product yield, easy availability of raw materials, and easy operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

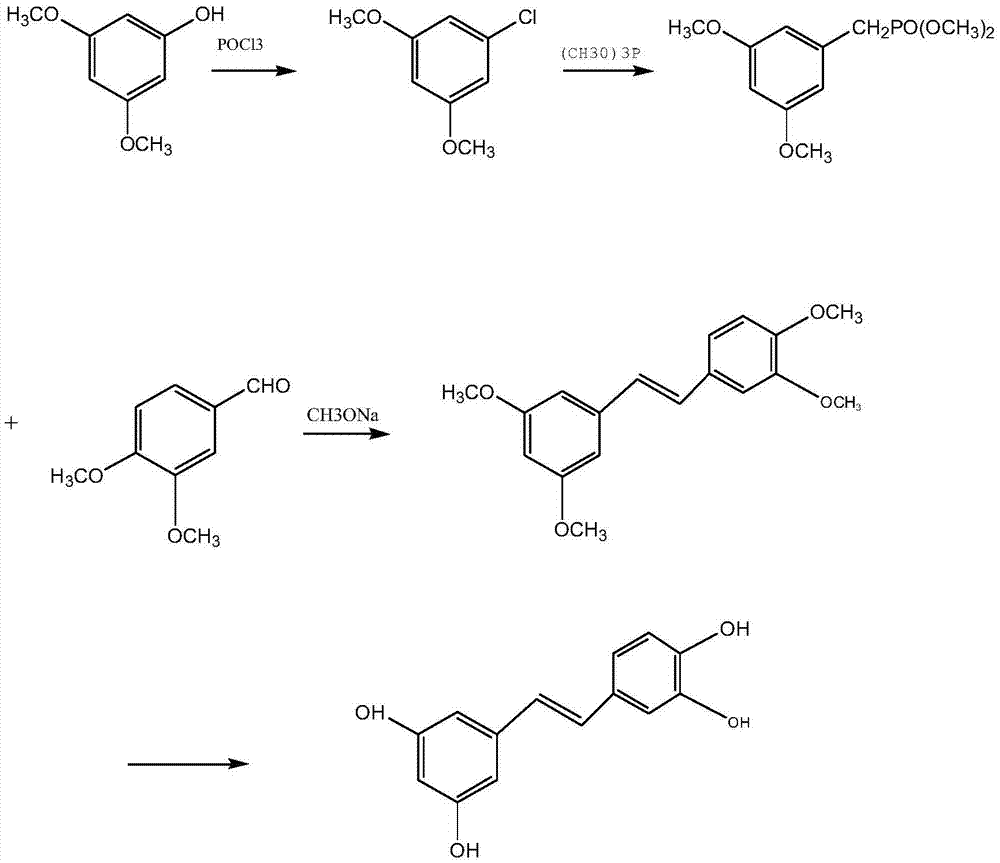

[0023] 1, Preparation of 3,5-dimethoxybenzyl chloride

[0024] Put 42g of 3,5 dimethoxybenzyl alcohol and 126ml of phosphorus oxychloride into a dry 500ml four-necked reaction flask, heat up and reflux for about 2 hours, TLC detection, the raw materials are basically reacted, pressurize and recover the solvent to 1 / 3 and cool down To 0-5°C, slowly add 150ml of water dropwise, after the addition is complete, stir at room temperature for 2h, filter, wash with water to neutralize, and dry under reduced pressure to obtain 45g of white solid with a yield of 96.7%.

[0025] 2. Preparation of Tetramethoxypitetanol

[0026] Into a dry 500ml four-necked reaction flask, put 37.2g of 3,5-dimethoxybenzyl chloride, 27g of trimethyl phosphite, 80ml of N,N-dimethylformamide, heat up and reflux for 4.5h, TLC detection, The starting material 3,5-dimethoxybenzyl chloride disappeared. Cool down to 5-10°C, add 29.8g of 28% methanolic sodium methoxide solution dropwise, keep stirring at this tem...

Embodiment 2

[0029] 1, Preparation of 3,5-dimethoxybenzyl chloride

[0030] Put 42g of 3,5 dimethoxybenzyl alcohol and 170ml of phosphorus oxychloride into a dry 500ml four-necked reaction flask, heat up and reflux for about 2 hours, TLC detection, the raw materials have basically reacted, pressurize and recover the solvent to 1 / 3 and cool down To 0-5°C, slowly add 180ml of water dropwise, after the addition is complete, stir at room temperature for 2h, filter, wash with water to neutralize, dry under reduced pressure to obtain 43.5g of white solid, yield 93.5%.

[0031] 2. Preparation of Tetramethoxypitetanol

[0032] In a dry 500ml four-necked reaction flask, put 37.2g of 3,5-dimethoxybenzyl chloride, 24.8g of trimethyl phosphite, and 120ml of N,N-dimethylformamide, heat up and reflux for 4 hours, and detect by TLC. The starting material 3,5-dimethoxybenzyl chloride disappeared. Cool down to 5-10°C, add 29.8g of 28% methanolic sodium methoxide solution dropwise, keep stirring at this t...

Embodiment 3

[0035] 1, Preparation of 3,5-dimethoxybenzyl chloride

[0036] Put 42g of 3,5 dimethoxybenzyl alcohol and 200ml of phosphorus oxychloride into a dry 500ml four-neck reaction flask, heat up and reflux for about 3 hours, TLC detection, the raw materials are basically reacted, pressurize and recover the solvent to 1 / 3 to cool down To 0-5°C, slowly add 200ml of water dropwise, after the addition is complete, stir at room temperature for 2h, filter, wash with water to neutralize, and dry under reduced pressure to obtain 43.4g of white solid with a yield of 94.5%.

[0037] 2. Preparation of Tetramethoxypitetanol

[0038] In a dry 500ml four-necked reaction flask, put 37.2g of 3,5-dimethoxybenzyl chloride, 29.7g of trimethyl phosphite, 80ml of N,N-dimethylformamide, heat up and reflux for 3.5h, and detect by TLC , the raw material 3,5-dimethoxybenzyl chloride disappeared. Cool down to 5-10°C, add dropwise 44g of 28% methanolic sodium methoxide solution, keep stirring at this temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com