A kind of multi-layer degradable pipe material, bracket and preparation method thereof

A technology for pipes and degrading polymers, applied in the field of medical devices, can solve the problems of insufficient radial strength of composite pipes, reducing effective components of drugs, and being prone to brittle fracture. Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the multilayer degradable pipe provided by the present invention includes the following steps:

[0043] a) Select the polymer materials of the inner layer and the outer layer with a crystallinity of less than 20%, and obtain the original pipe through multi-layer extrusion; preferably, the polymer materials of the inner layer and the outer layer are placed in Multi-layer extrusion is carried out in the barrel of the layer extruder.

[0044] b) Put the original pipe into a tubular mold with good thermal conductivity and not easy to deform, the inner diameter of the mold is equal to the required outer diameter of the pipe after expansion;

[0045] c) Heating the original pipe and tubular mold to a temperature T, the range of the temperature T is: higher than the highest glass transition temperature Tg of the polymer (ie the highest glass transition temperature of all layers of polymer), lower than the polymer The lowest melting temperature Tm of the mat...

Embodiment 1

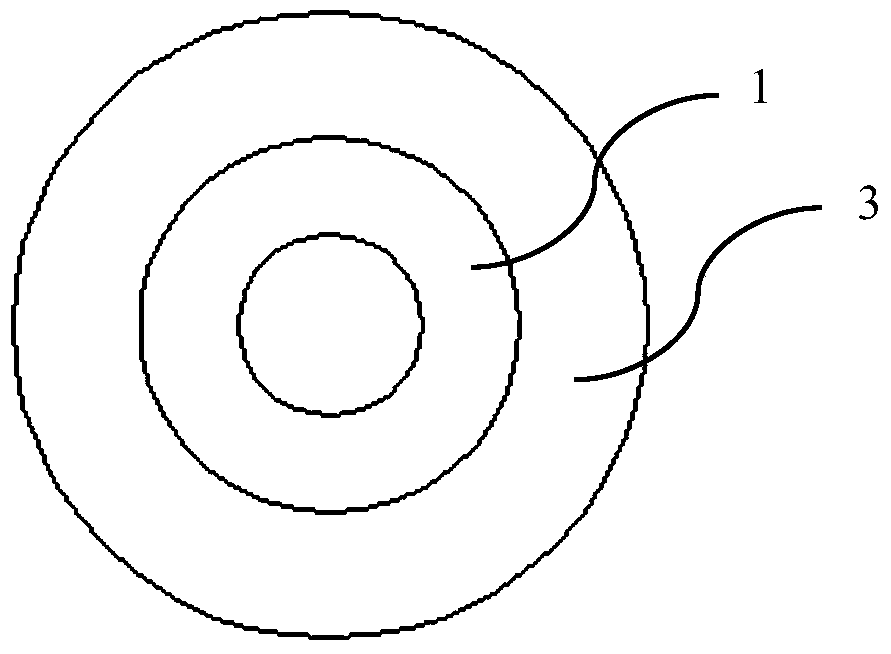

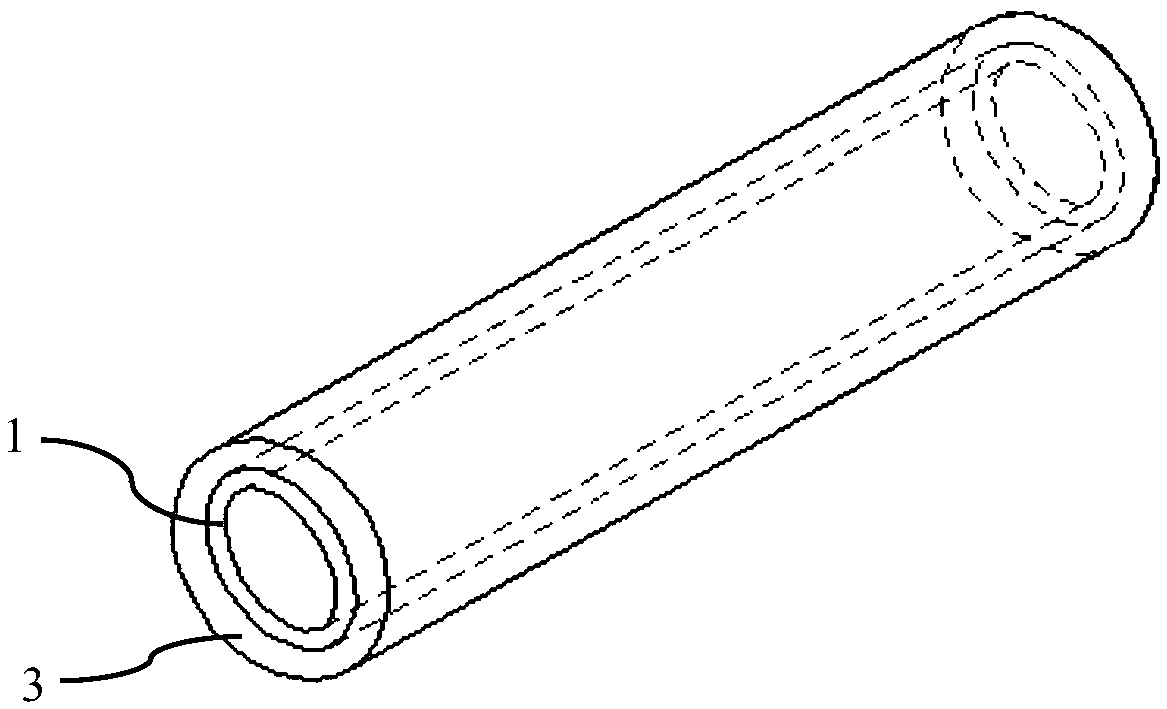

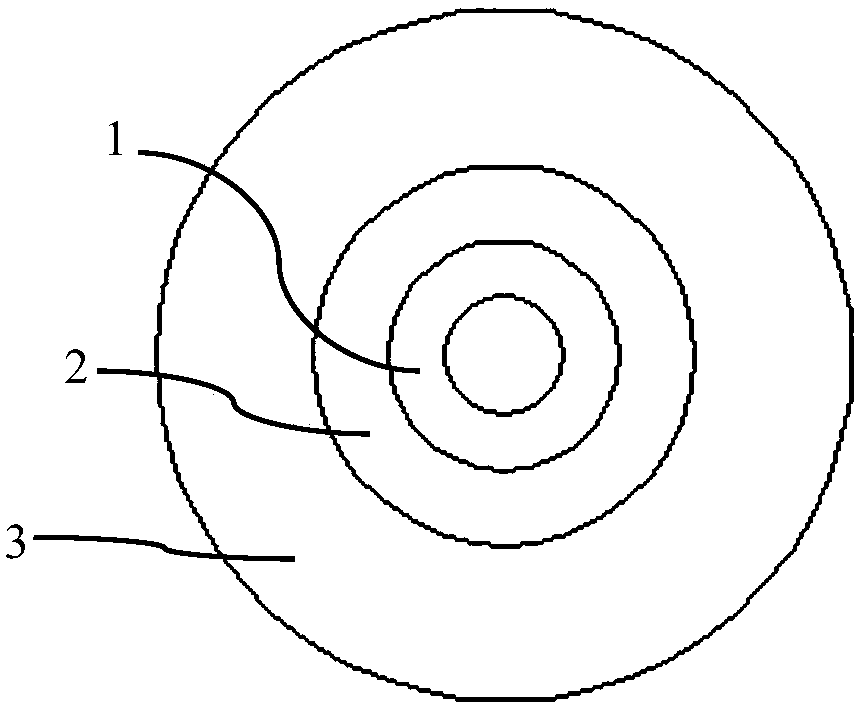

[0050] (1) In this embodiment, the original extruded pipe has two layers inside and outside; figure 1 with figure 2 As shown, the polymer material of the outer layer 3 is L-polylactic acid, and the polymer material of the inner layer 1 is a polylactic acid-caprolactone copolymer. The ratio of the polylactic acid-caprolactone copolymer is polylactic acid / caprolactone= 90 / 10.

[0051] (2) Place the inner and outer polymer materials in the barrel of the multilayer extruder respectively, and obtain the original multilayer extruded pipe with an outer diameter of 1.45 mm and a wall thickness of 0.515 mm through extrusion. Among them, the outer polymer wall thickness is 0.192mm, and the inner polymer wall thickness is 0.323mm.

[0052] (3) Inflate radially and axially stretch the pipe to an outer diameter of 3.0mm and an inner diameter of 2.7mm. Processing temperature is 80℃;

[0053] (4) Using femtosecond laser cutting technology to prepare a double-layer biodegradable scaffold. After ...

Embodiment 2

[0058] (1) In this embodiment, the original extruded pipe has two layers inside and outside, such as figure 1 with figure 2 As shown, the polymer material of the outer layer 3 is L-polylactic acid, and the polymer material of the inner layer 1 is a copolymer of polylactic acid and caprolactone. The ratio of the copolymer of polylactic acid and caprolactone is polylactic acid / caprolactone=70 / 30.

[0059] (2) Place the inner and outer layer polymer materials in the barrel of the multilayer extruder, and obtain the original multilayer extruded pipe with an outer diameter of 1.45 mm and a wall thickness of 0.515 mm through extrusion. Among them, the outer polymer wall thickness is 0.192mm, and the inner polymer wall thickness is 0.323mm.

[0060] (3) Inflate radially and axially stretch the pipe to an outer diameter of 3.0mm and an inner diameter of 2.7mm. Processing temperature is 80℃;

[0061] (4) Using femtosecond laser cutting technology to prepare a double-layer biodegradable sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com