In-situ MgO template preparing method and application of magnetic mesoporous carbon nanospheres with high adsorptive property

A nano-microsphere, high-adsorption technology, used in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 0.6g magnesium citrate at 600, 700 and 800 o Under the condition of C, calcined under the condition of tube furnace under nitrogen atmosphere for 2h, and the heating rate was 5 o C / min, use 0.5molL of the calcined product -1 HNO 3 After washing away the MgO template, wash it with high-purity water several times, and dry it for storage.

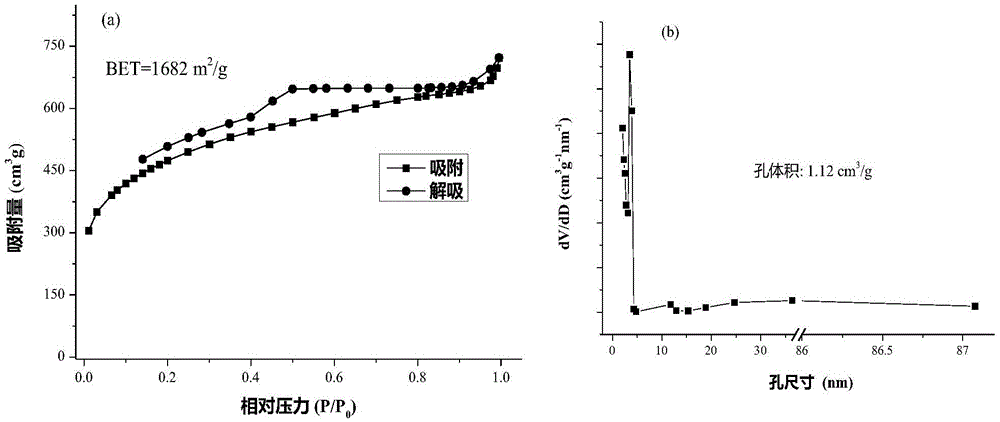

[0038] figure 1 is Magnesium Citrate 600 o N of the mesoporous carbon material obtained after C calcination 2 Adsorption / desorption curve (a) and particle size distribution curve (b), it can be seen from the figure that the specific surface area of the material can be as high as 1682m 2 / g, the micropore specific surface area is 466m 2 / g, rich mesopore specific surface area up to 1216m 2 / g, the largest pore volume is 1.12cm 3 / g, the pore size of the prepared mesoporous carbon material is 3.7nm. Compared with other carbon-based materials prepared in the literature, the specific surface area of this material is at a highe...

Embodiment 2

[0040] Preparation of Fe 3 o 4 Magnetic nanoparticles: prepared by co-precipitation method, dissolving 11.68g of ferric chloride and 4.30g of ferrous chloride in 200mL of high-purity water, stirring and heating to 85°C under nitrogen protection. Then quickly add 25mL of 30wt% NH 3 . h 2 O, the color of the solution changes rapidly from orange to black, and stops after 30 minutes of reaction. After cooling to room temperature, wash with water for several times and then wash with ethanol for 3 times to obtain magnetic Fe with a particle size of 10-20nm. 3 o 4 nanosphere 。

[0041] Preparation of Fe 3 o 4 nSiO 2 Nanoparticles: Pipette half of the above Fe 3 o 4 Put the magnetic nanoparticles into a mixed solvent of 160mL ethanol and 40mL high-purity water, and add 5mL of 30wt% NH 3 . h 2 0 and 6mLTEOS, then reacted at room temperature for 12h under mechanical stirring conditions, and after the reaction was completed, washed several times with high-purity water and e...

Embodiment 3

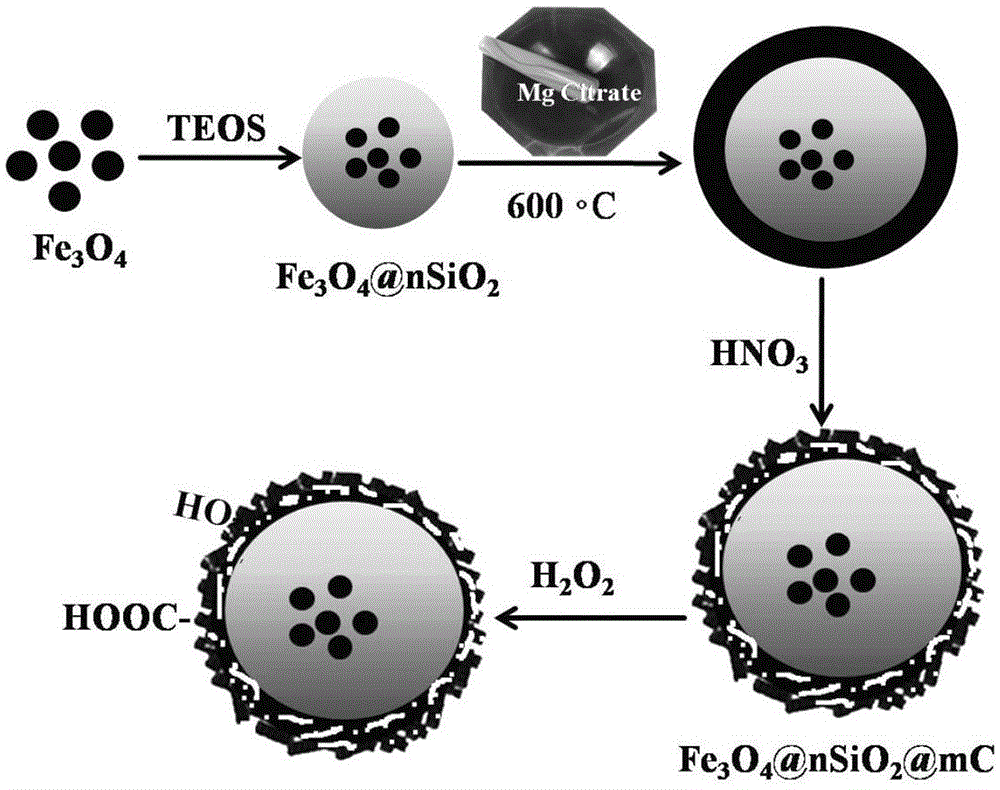

[0044] Fe in Example 2 3 o 4 nSiO 2 The Fe prepared when the mass ratio with magnesium citrate is 0.5 / 9.5 3 o 4 nSiO 2 Add 10mL30wt%H to mC 2 o 2 in (keep H 2 o 2 with Fe 3 o 4 nSiO 2 The solid-to-liquid ratio of mC is 50gL -1 ), after ultrasonic mixing, static reaction in the dark for 12h, followed by washing and drying to obtain Fe 3 o 4 nSiO 2 mC-H 2 o 2 , magnetic mesoporous carbon (Fe 3 o 4 nSiO 2 mC-H 2 o 2 ) for the synthesis of figure 2 shown.

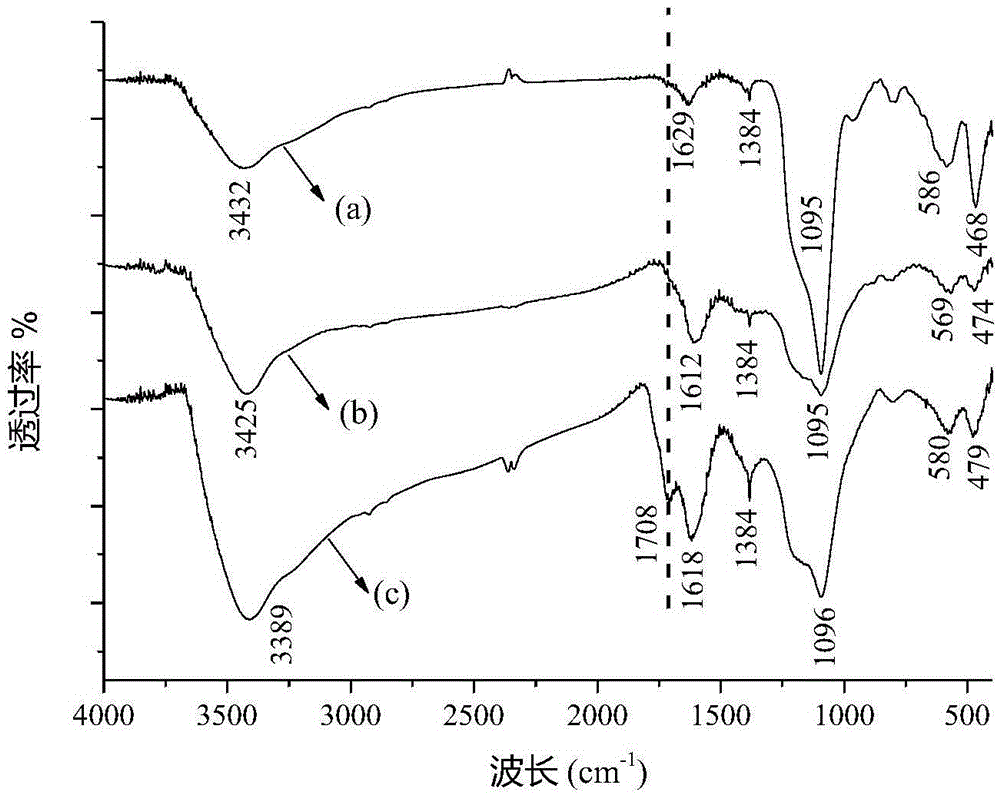

[0045] image 3 It is the Fe prepared in Example 2 3 o 4 nSiO 2 and Fe 3 o 4 nSiO 2 mC (Fe 3 o 4 nSiO 2 and the mass ratio of magnesium citrate is 0.5 / 9.5) and the Fe prepared in Example 3 3 o 4 nSiO 2 mC-H 2 o 2 The infrared spectrum of the figure, where, image 3 a is Fe 3 o 4 nSiO 2 The infrared spectrum; image 3 b is Fe 3 o 4 nSiO 2 Infrared spectrum of mC; image 3 c is Fe 3 o 4 nSiO 2 mC-H 2 o 2 Infrared spectrum chart. In the picture, 580cm -1 The left and right are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com