Preparation method of in-situ self-assembling N-doped super-hydrophilic carbon aerogel supercapacitor electrode material

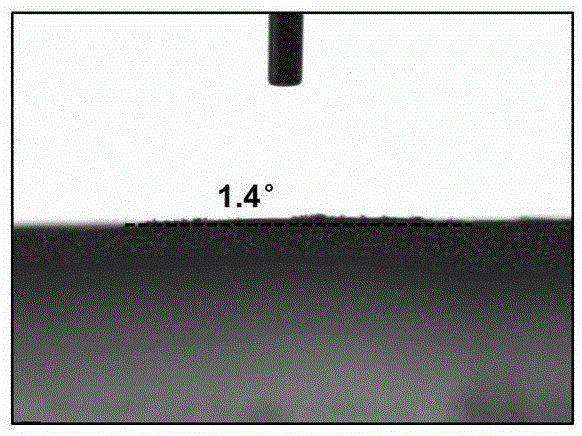

A technology of supercapacitors and carbon aerogels, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of scarce fish scale resources, poor electrochemical performance of materials, and complex synthesis processes, etc. Inexpensive, improve capacitance performance, and promote the effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Dissolve 10g of polyvinyl alcohol (PVA) in 100mL of hydrochloric acid solution with a molar concentration of 0.5mol / L at 80°C in a water bath, stir for 2h, turn to room temperature, add 1.715g of N-hydroxyethylaniline, stir for 30min, add 5mL solution containing 2.853g ammonium persulfate, stirred for 30min, then added 100mL solution containing 5g boric acid, aged at room temperature for 24h, freeze-dried to obtain A1;

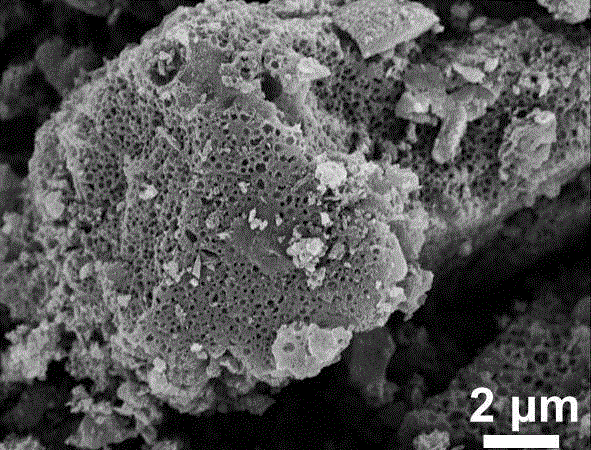

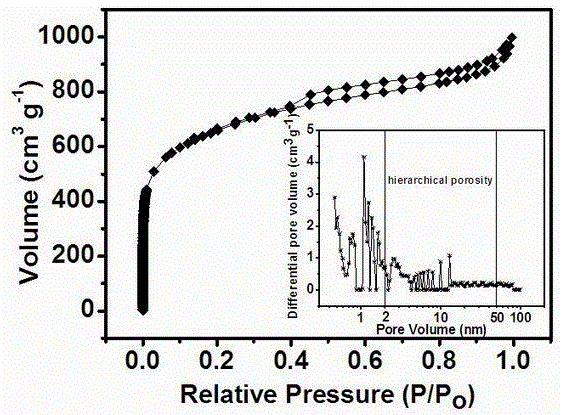

[0020] Under a nitrogen atmosphere, heat up A1 to 700°C at a rate of 5°C / min and carbonize it for 2 hours to obtain B1, then mix B1 and potassium hydroxide activator in an aqueous solution at a mass ratio of 1:4 for 12 hours, and place in an oven at 105°C Dry it, then place it in a tube furnace, and activate it at a rate of 5°C / min to 700°C for 2 hours under a nitrogen atmosphere, soak the activated material in a hydrochloric acid solution with a molar concentration of 2mol / L for 12 hours, and filter , washed with pure water until neutral, and dried in ...

Embodiment 2

[0027] Dissolve 10g of polyvinylpyrrolidone (PVP) in 100mL of hydrochloric acid solution with a molar concentration of 1.0mol / L at a water bath temperature of 60°C, stir for 1h, turn to room temperature, add 1.164g of aniline, stir for 30min, add 5mL of A solution containing 2.853g of ammonium persulfate was stirred for 60 minutes, then 100mL of a solution containing 5g of boric acid was added, aged at room temperature for 24 hours, and freeze-dried to obtain A2;

[0028] Under a nitrogen atmosphere, heat up A2 to 600°C at a rate of 5°C / min and carbonize it for 3 hours to obtain B2, then mix B2 and sodium hydroxide activator in an aqueous solution at a mass ratio of 1:2 for 12 hours, and place in an oven at 105°C Dry it, then place it in a tube furnace, and activate it at a rate of 10°C / min to 800°C for 2 hours under a nitrogen atmosphere, soak the activated material in a hydrochloric acid solution with a molar concentration of 2mol / L for 12 hours, filter , washed with pure wa...

Embodiment 3

[0033] Dissolve 12g of polyacrylamide (PAAm) in 100mL of sulfuric acid solution with a molar concentration of 0.5mol / L at a water bath temperature of 85°C, stir for 3h, turn to room temperature, add 1.327g of N-methylaniline, stir for 45min, then Add 5 mL of a solution containing 2.853 g of ammonium persulfate, stir for 30 minutes, then add 100 mL of a solution containing 6 g of boric acid, age at room temperature for 36 hours, and freeze-dry to obtain A3;

[0034] Under an argon atmosphere, heat A3 up to 500°C at a rate of 5°C / min and carbonize it for 4 hours to obtain B3, then mix B3 and potassium carbonate activator in an aqueous solution at a mass ratio of 1:5 for 12 hours, and place in an oven at 105°C Dry it, then place it in a tube furnace, and activate it at a rate of 10°C / min to 900°C for 2 hours under an argon atmosphere, and soak the activated material in a hydrochloric acid solution with a molar concentration of 2mol / L for 12 hours. Filter, wash with pure water unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com