A kind of preparation method of high yield mesoporous activated carbon

A mesoporous activated carbon, high yield technology, applied in the field of activated carbon, can solve the problems of large consumption of strong corrosive acid to remove the template, large amount of template agent, low product yield, etc., to achieve high yield, low production cost, high product yield high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

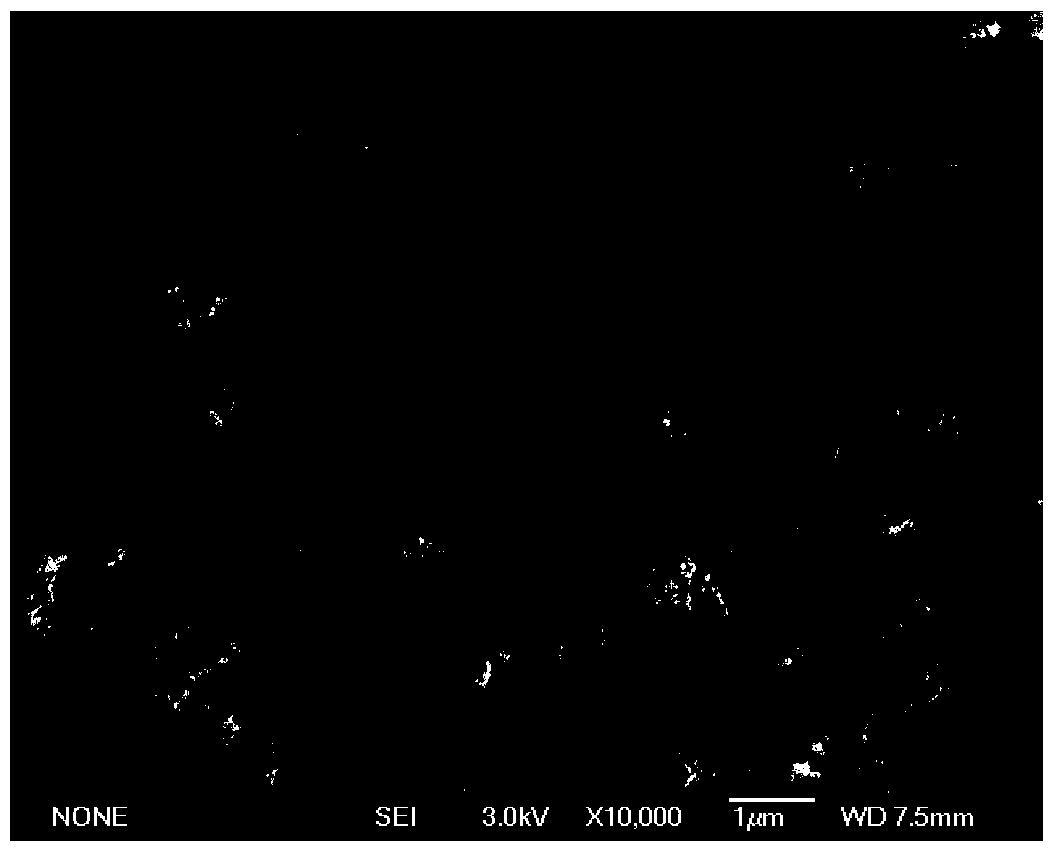

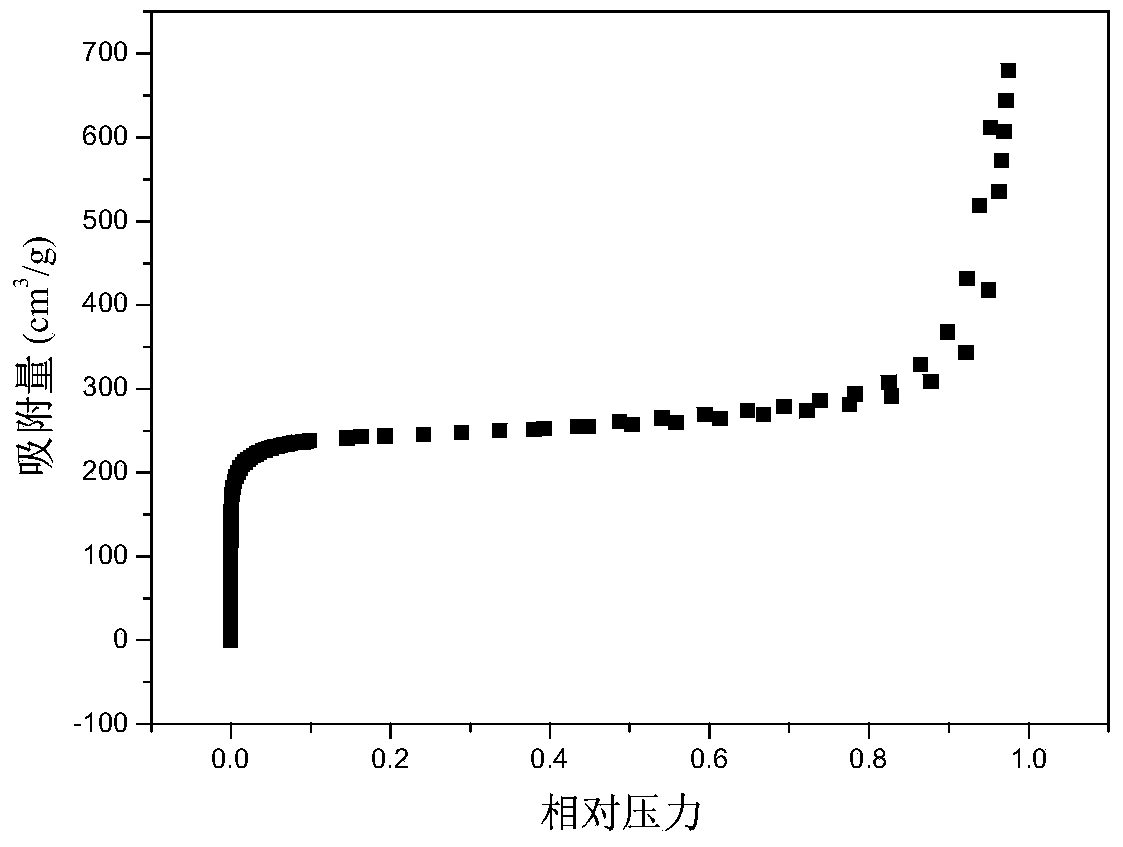

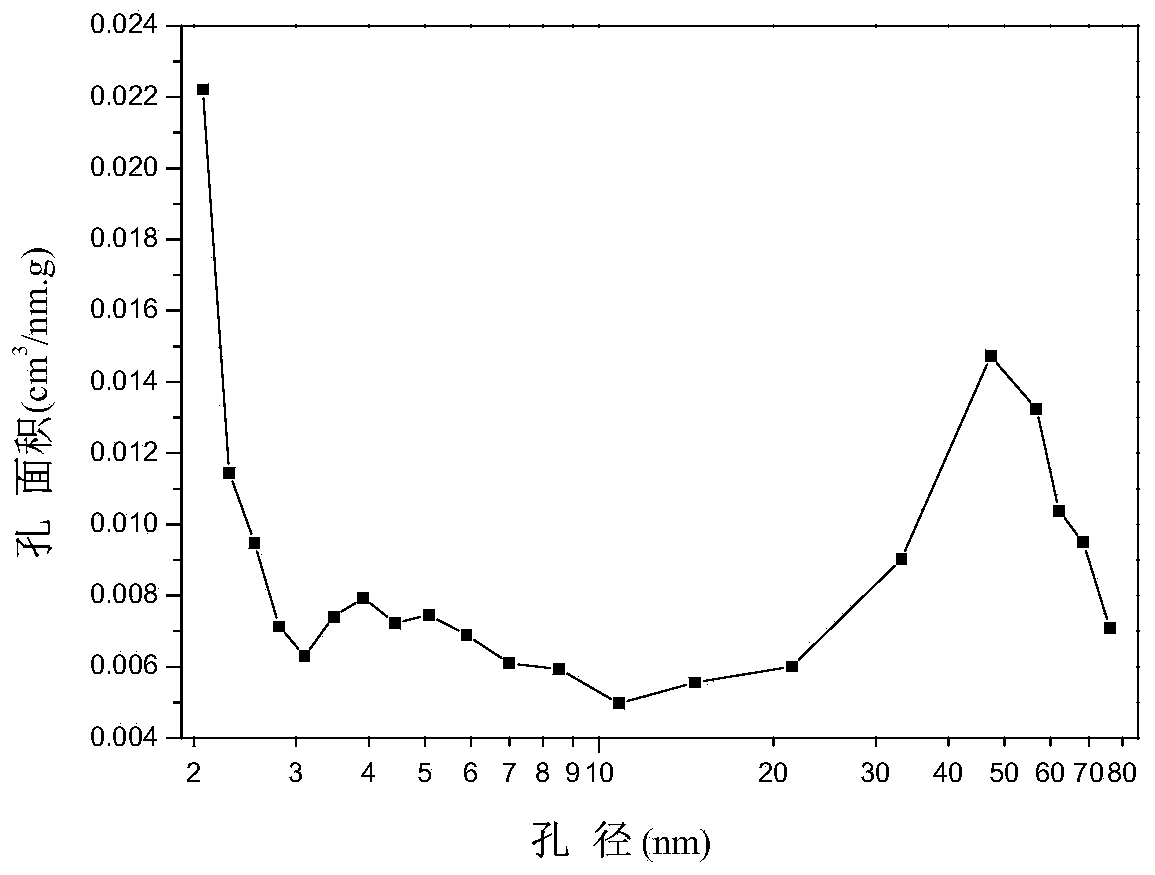

Image

Examples

Embodiment 1

[0036] A preparation method of high-yield mesoporous activated carbon, the steps are as follows:

[0037] (1) collect Enteromorpha and dry naturally, pulverize and pass through a 100-mesh sieve to obtain Enteromorpha powder;

[0038] (2) At room temperature, fully mix Enteromorpha powder and ammonium polyphosphate powder according to the mass ratio of 5:1, then add deionized water according to the ratio of ammonium polyphosphate powder and deionized water mass ratio of 1:1.5, and stir Mix evenly to obtain a mixture;

[0039] (3) Put the mixed material in ultrasonic, ultrasonically mix for 20min, and then impregnate at room temperature for 12h to obtain the impregnated material;

[0040](4) Place the impregnated material in a tube-type resistance furnace, raise the temperature to 600°C at a heating rate of 10°C / min, and continue the activation treatment for 1 hour. The activation process does not need nitrogen gas. After activation and cooling, take out the activation materia...

Embodiment 2

[0044] A preparation method of high-yield mesoporous activated carbon, the steps are as follows:

[0045] (1) collect Enteromorpha and dry naturally, pulverize and pass through a 150-mesh sieve to obtain Enteromorpha powder;

[0046] (2) At room temperature, fully mix Enteromorpha powder and ammonium polyphosphate powder according to the mass ratio of 2:1, then add deionized water according to the ratio of ammonium polyphosphate powder and deionized water mass ratio of 1:1, and stir Mix evenly to obtain a mixture;

[0047] (3) Put the mixed material in ultrasonic, ultrasonically mix for 10 minutes, and then impregnate at room temperature for 24 hours to obtain the impregnated material;

[0048] (4) Place the impregnated material in a tube-type resistance furnace, raise the temperature to 650°C at a heating rate of 10°C / min, and continue the activation treatment for 1 hour. The activation process does not need nitrogen gas. After activation and cooling, take out the activatio...

Embodiment 3

[0050] A preparation method of high-yield mesoporous activated carbon, the steps are as follows:

[0051] (1) collect Enteromorpha and dry naturally, pulverize and pass through a 200-mesh sieve to obtain Enteromorpha powder;

[0052] (2) At room temperature, fully mix Enteromorpha powder and ammonium polyphosphate powder according to the mass ratio of 3:1, then add deionized water according to the ratio of ammonium polyphosphate powder and deionized water mass ratio of 1:2, and stir Mix evenly to obtain a mixture;

[0053] (3) Put the mixed material in ultrasonic, ultrasonically mix for 30min, and then impregnate at room temperature for 24h to obtain the impregnated material;

[0054] (4) Place the impregnated material in a tube-type resistance furnace, raise the temperature to 550°C at a heating rate of 10°C / min, and continue the activation treatment for 1 hour, without nitrogen gas being introduced during the activation process. After activation and cooling, take out the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com