A kind of synthetic method of morpholine amididine hydrochloride

A technology for the synthesis of morpholine amididine hydrochloride and its synthesis method, which is applied in the field of synthesis of morpholine amididine hydrochloride, can solve the problems of difficult industrial application, large hydrogen peroxide oxidation heat release, and low yield, and achieve less waste liquid discharge and environmental protection , the effect of reducing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

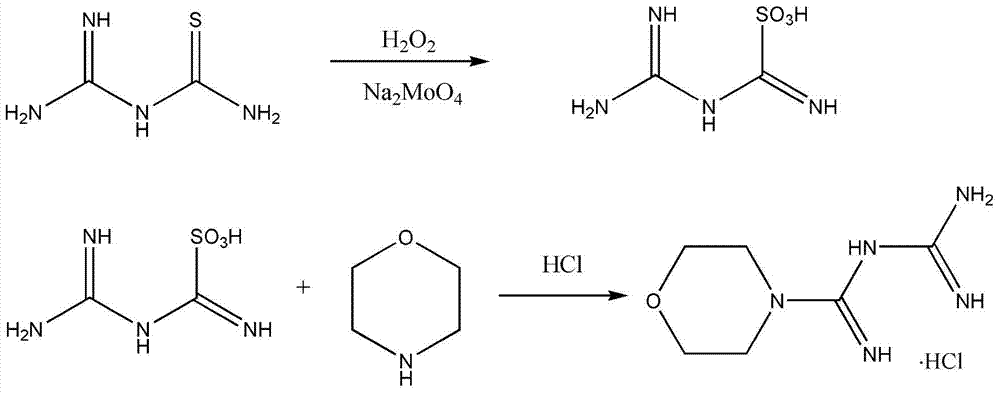

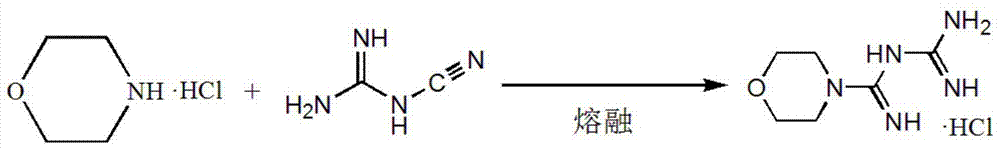

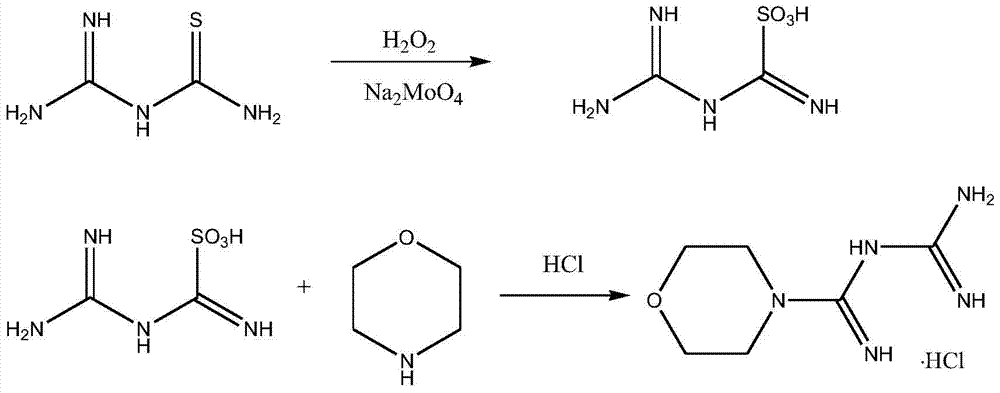

Method used

Image

Examples

Embodiment 1

[0039] (1) add diethylene glycol 2.1Kg, dicyandiamide 2.0Kg, ammonium chloride 1.4Kg successively in the reactor of 10L band mechanical stirrer, mass mass concentration is the sulfuric acid aqueous solution 0.5Kg of 30%, under sealed stirring state , the temperature was raised to 120°C at a rate of 3°C per minute, the pressure of the reactor was raised to 0.3MPa, and after 1 hour of reaction, the reaction temperature was naturally cooled to room temperature to obtain a white emulsion;

[0040](2) Transfer the white emulsion to a 50L glass reactor, add 15Kg of 95% ethanol, heat and reflux for 30 minutes to obtain a mixed solution, heat the mixed solution through a filter cartridge to a crystallization kettle, and cool the filtrate in a crystallization kettle After reaching room temperature, white crystals were precipitated, and after centrifugation, they were dried in a hot air oven at 80°C to obtain 5.2Kg of morpholine amididine hydrochloride, with a yield of 81% based on dicya...

Embodiment 2

[0042] (1) add diethylene glycol 3.1Kg, dicyandiamide 3.0Kg, ammonium chloride 2.0Kg successively in the reactor of 10L band mechanical stirrer, mass concentration is the aqueous solution 0.5Kg of 20% sulfuric acid, under sealed stirring state, Raise the temperature to 120°C at a rate of 3°C per minute, and raise the pressure of the reactor to 0.5MPa. After reacting for 1 hour, naturally cool the reaction temperature to room temperature to obtain a white milky product;

[0043] (2) Transfer the white emulsion to a 50L glass reaction kettle, add 28Kg of 95% ethanol, heat and reflux for 30 minutes to obtain a mixed solution, heat the mixed solution through a filter cartridge to a crystallization kettle, and cool the filtrate in a crystallization kettle After reaching room temperature, white crystals were precipitated, and after centrifugation, they were dried in a hot air oven at 85°C to obtain 6.2Kg of morpholine amididine hydrochloride, with a yield of 83% based on dicyandiamid...

Embodiment 3

[0045] (1) add diethylene glycol 2.6Kg, dicyandiamide 2.5Kg, ammonium chloride 1.6Kg successively in the reactor of 10L band mechanical stirrer, mass concentration is 0.5Kg of aqueous sulfuric acid solution of 20%, under sealed stirring state, Raise the temperature to 130°C at a rate of 5°C per minute, and raise the pressure of the reactor to 0.4MPa. After reacting for 1 hour, naturally cool the reaction temperature to room temperature to obtain a white milky product;

[0046] (2) Transfer the white emulsion to a 50L glass reaction kettle, add 20Kg of 95% ethanol, heat and reflux for 30 minutes to obtain a mixed solution, heat the mixed solution through a filter cartridge to a crystallization kettle, and cool the filtrate in a crystallization kettle After reaching room temperature, white crystals were precipitated. After centrifugation, they were dried in a hot air oven at 80° C. to obtain 5.3 kg of morpholine amididine hydrochloride, with a yield of 85% based on dicyandiamide....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com