Anticorrosive polyaniline/silicon carbide/graphene composite coating and preparation method thereof

A graphene composite, anti-corrosion coating technology, applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings and other directions, can solve the problems of metal substrate surface coating damage, general anti-corrosion coating effect, stacking performance and other problems, to achieve excellent anti-corrosion performance, Easy to scale industrial production, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

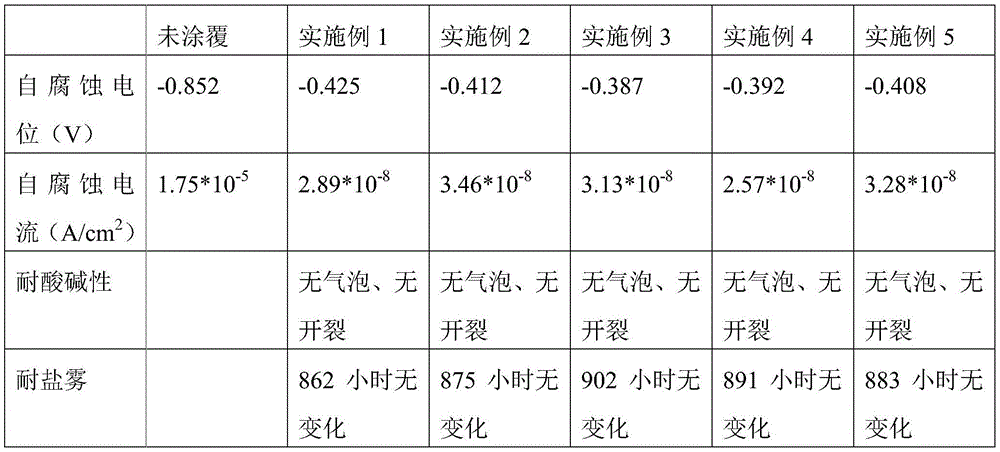

Examples

Embodiment 1

[0029] It is composed of the following components in terms of mass ratio percentage, epoxy resin E51 is 50, polyaniline / silicon carbide / graphene composite material is 5, polyamide curing agent is 15, plasticizer dibutyl phthalate is 2 , the defoamer fluorosilicone Airex931 is 1, and the solvent N-methylpyrrolidone is 27.

[0030] 1) Add 0.5g of silicon carbide into sodium dodecylbenzenesulfonate aqueous solution, ultrasonically disperse for 10 minutes, add aniline, stir and mix evenly at 0°C, the concentration of sodium dodecylbenzenesulfonate is 20mg / mL, and the concentration of aniline 0.15mol / L;

[0031] 2) Prepare an aqueous solution containing ferric chloride with pH=1, cool to 0° C., and the molar ratio of ferric chloride to aniline is 1.5:1;

[0032] 3) Mix the solution of step 1) and step 2), stir and react at 0°C for 8 hours, filter, wash, and dry to obtain a polyaniline / silicon carbide composite material;

[0033] 4) Disperse the polyaniline / silicon carbide composi...

Embodiment 2

[0037] It is composed of the following components in terms of mass ratio, epoxy resin E44 is 45, polyaniline / silicon carbide / graphene composite material is 8, polyamide curing agent is 18, plasticizer dibutyl phthalate is 5, The antifoaming agent fluorosilicone Airex932 is 1, and the solvent n-butanol is 23.

[0038] 1) Add 0.6g of silicon carbide into the sodium dodecylbenzenesulfonate aqueous solution, ultrasonically disperse for 15 minutes, add aniline, stir and mix evenly at 2°C, the concentration of sodium dodecylbenzenesulfonate is 30mg / mL, and the concentration of aniline is 0.3mol / L;

[0039] 2) Prepare an aqueous solution containing ferric nitrate with pH=2, cool to 2°C, and the molar ratio of ferric nitrate to aniline is 1:1;

[0040] 3) Mix the solution of step 1) and step 2), stir and react at 2°C for 12 hours, filter, wash, and dry to obtain a polyaniline / silicon carbide composite material;

[0041] 4) Disperse the polyaniline / silicon carbide composite material ...

Embodiment 3

[0045] It is composed of the following components in terms of mass ratio, epoxy resin E42 is 60, polyaniline / silicon carbide / graphene composite material is 8, polyetheramine curing agent is 10, plasticizer dioctyl phthalate is 4 , the defoamer organomodified polysiloxane Airex962 is 1, and the solvent xylene is 17.

[0046] 1) Add 0.8g of silicon carbide into sodium dodecylbenzenesulfonate aqueous solution, ultrasonically disperse for 30 minutes, add aniline, stir and mix evenly at 4°C, the concentration of sodium dodecylbenzenesulfonate is 40mg / mL, and the concentration of aniline 0.4mol / L;

[0047] 2) Prepare an aqueous solution containing an oxidizing agent with pH=4, and cool it to 4°C. The oxidizing agent is ferric chloride, ferric nitrate, or ammonium persulfate, and the molar ratio of the oxidizing agent to aniline is 2:1;

[0048] 3) Mix the solution of step 1) and step 2), stir and react at 4°C for 12 hours, filter, wash, and dry to obtain a polyaniline / silicon carbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com