Bacitracin and preparation method of zinc salt thereof

The technology of bacitracin zinc and bacitracin is applied in the field of preparation of bacitracin and its zinc salt bacitracin zinc, which can solve the problems of low total yield, difficult recovery and the like, and achieves short processing time, simple and fast operation, and simplified extraction. The effect of the purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

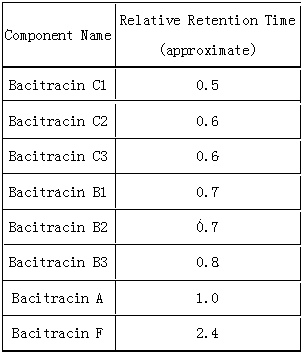

Image

Examples

preparation example Construction

[0030] Preparation of Seed Solution of Bacillus licheniformis Strain

[0031] The slant culture of the Bacillus licheniformis strain was inoculated into the seed medium, and cultured at 30° C. and 200 rpm for 20 hours to obtain a seed solution.

[0032] The seed medium described therein is obtained by the following method: 5.0 grams of cornstarch, 10.0 grams of glucose, 10.0 grams of yeast powder, 2.0 grams of ammonium sulfate, 2.0 grams of sodium chloride, 1.5 grams of magnesium sulfate heptahydrate, add tap water to be constant to 1000mL, pH7.0, sterilized at 121°C for 30 minutes.

[0033] The bacitracin producing bacterium of the present invention is the strain numbered ATCC10716.

[0034] Fermentation medium composition:

[0035] 30.0 grams of corn starch, 20.0 grams of glucose, 15.0 grams of cottonseed protein powder, 15.0 grams of yeast powder, 2.0 grams of ammonium sulfate, 4.0 grams of corn steep liquor, 1.5 grams of potassium dihydrogen phosphate, 2.5 grams of sodiu...

Embodiment 1

[0040] Get 500ml of bacitracin fermentation broth, fermentation unit 765U / ml, add 15 grams of superparamagnetic microspheres with a diameter of 20 μm to the culture broth, stir for half an hour, and magnetically separate the superparamagnetic microspheres in the fermentation broth. Collect the superparamagnetic microspheres and wash them twice with 30ml of deionized water, collect the washed superparamagnetic microspheres, soak them in 25ml of 2% ammonia solution for 20 minutes, separate the superparamagnetic microspheres, and collect the desorption solution once; then Soak in 20ml of 2% ammonia solution for 20 minutes, separate the superparamagnetic microspheres, and collect the secondary desorption liquid; combine the two desorption liquids to 43ml, and the HPLC content is 7828U / ml. Adjust the pH value to 6.0 with 2mol / L hydrochloric acid, extract with 20ml of n-butanol to obtain 24ml of n-butanol extract, add 120ml of acetone to the n-butanol extract, and precipitate bacitra...

Embodiment 2

[0042]2L of bacitracin fermentation broth, fermentation unit 744U / ml, 80 grams of superparamagnetic microspheres with a diameter of 20 μm were added to the culture broth, stirred for half an hour, and the superparamagnetic microspheres in the fermentation broth were separated magnetically. Collect the superparamagnetic microspheres and wash the magnetic field twice with 160ml deionized water, collect the washed superparamagnetic microspheres, soak them in 160ml4% ammonia solution for 20 minutes, separate the superparamagnetic microspheres, and collect the desorption solution once; Soak it in 160ml of 4% ammonia solution for 20 minutes, separate the superparamagnetic microspheres, and collect the secondary desorption solution; combine the two desorption solutions into 300ml, and the HPLC content is 4762U / ml. Adjust the pH value to 8.0 with 1 mol / L sulfuric acid, extract twice with 150ml of n-butanol to obtain 180ml of n-butanol extract, add 1440ml of acetone to the n-butanol ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com