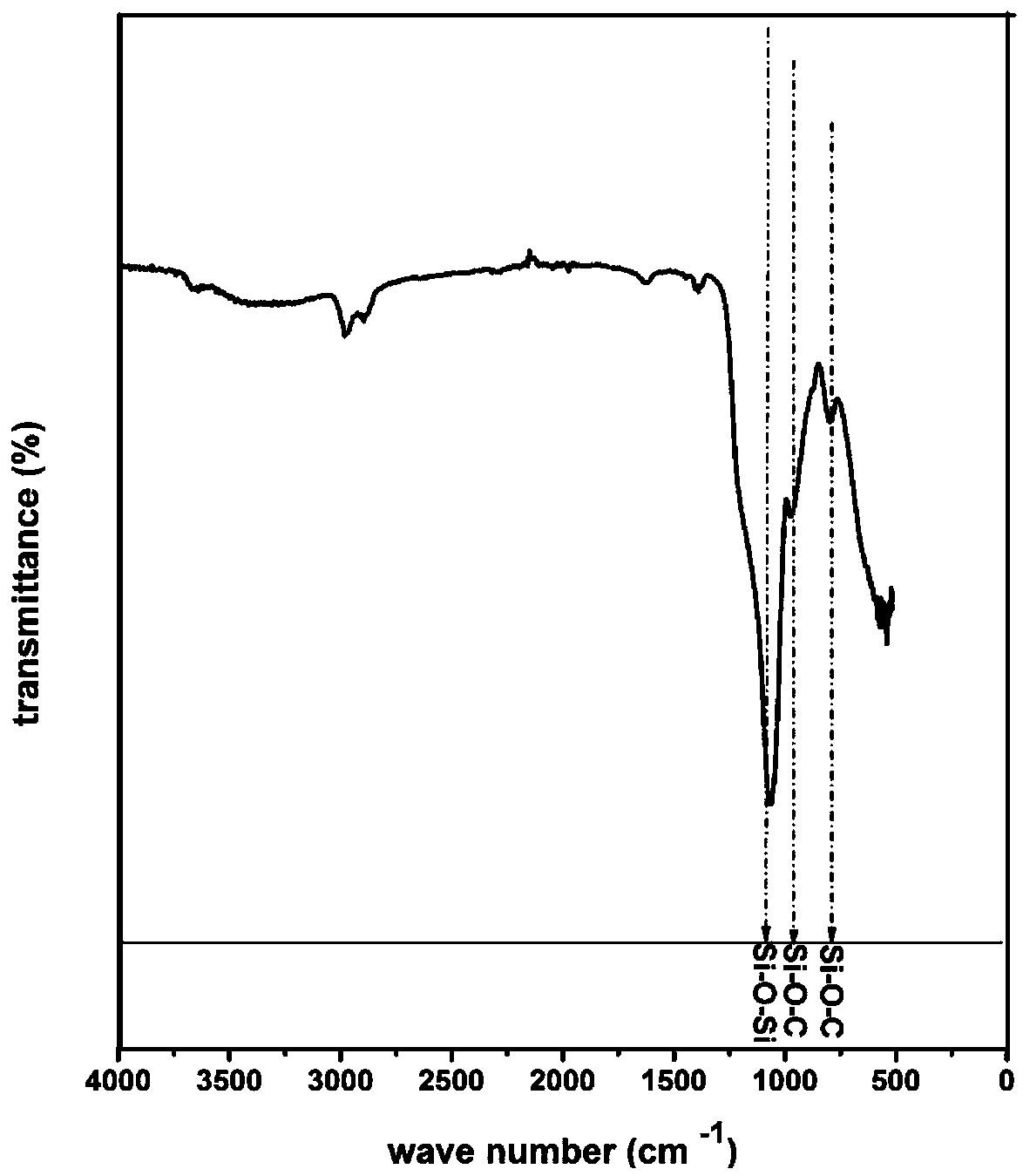

Method for preparing antimony-doped tin dioxide aerogel three-dimensional electrode through normal pressure drying

A tin dioxide, atmospheric drying technology, used in gel electrodes, battery electrodes, active material electrodes, etc., can solve the problems of high energy consumption, brittleness, high risk, and achieve low energy consumption, developed pore structure, The effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

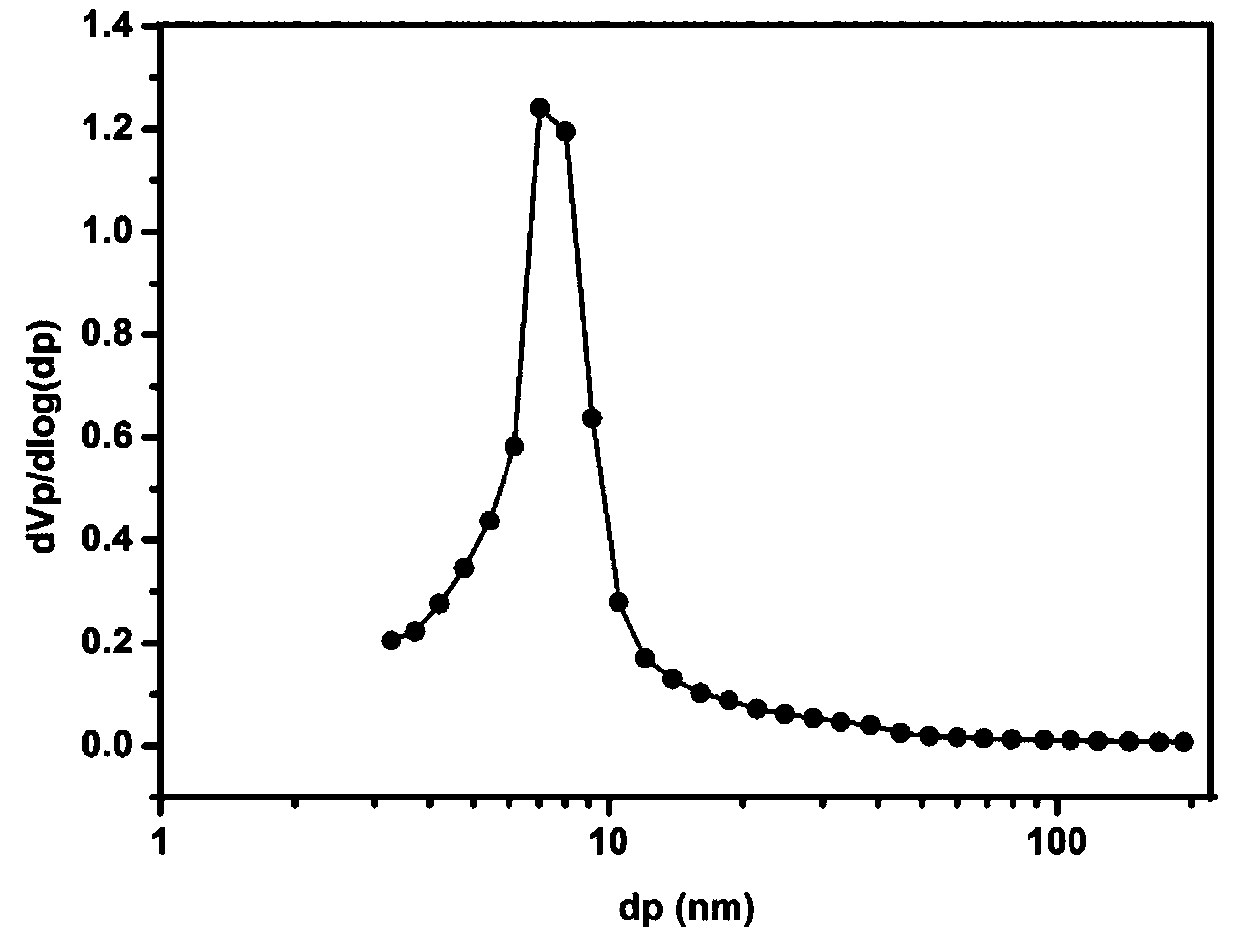

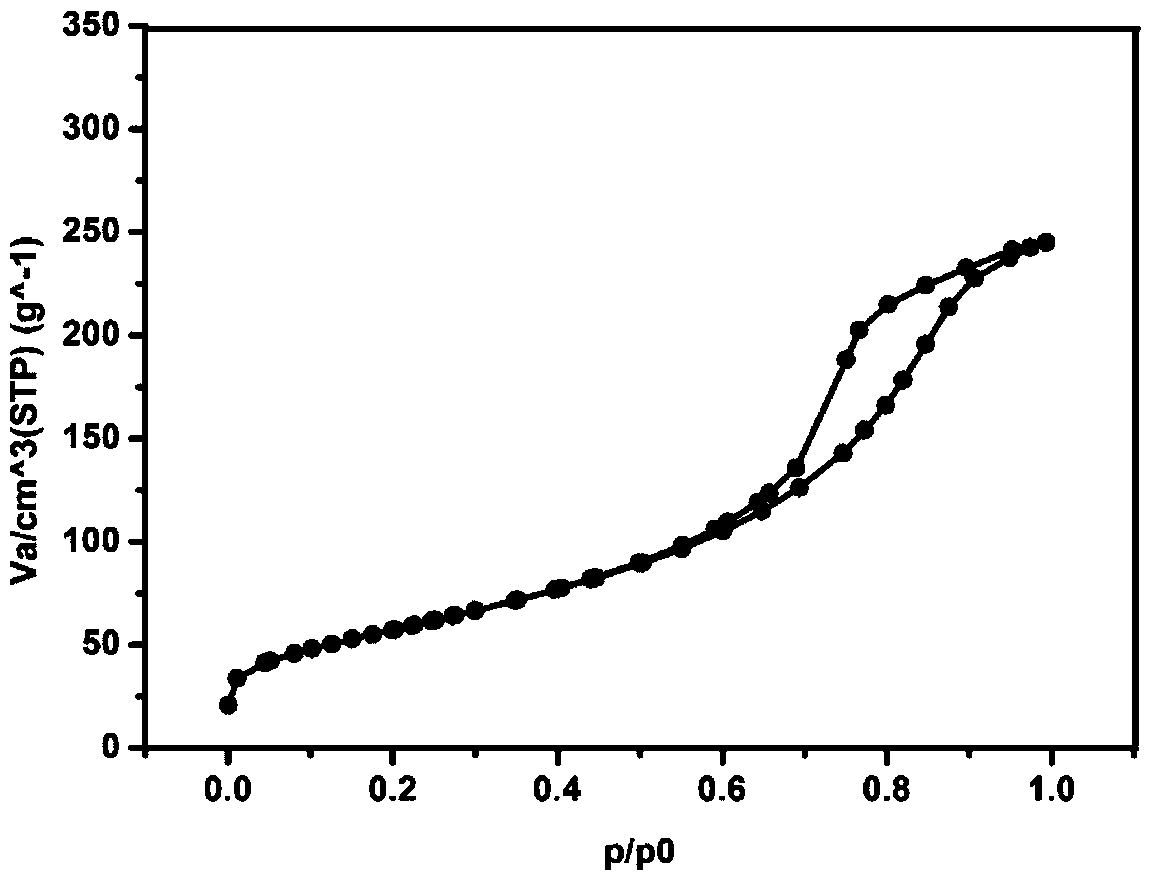

Embodiment 1

[0026] Dissolve tin tetrachloride pentahydrate in ethanol to prepare 0.6mol / L tin tetrachloride alcohol solution; dissolve ammonium fluoride in water to prepare 7mol / L ammonium fluoride aqueous solution. Stir the tin tetrachloride alcohol solution in a water bath at 60°C for 5 hours, and add the ammonium fluoride aqueous solution dropwise when the stirring starts, and the molar ratio of fluorine to tin is 1:1. Dissolve antimony trichloride in hydrochloric acid to prepare a 2mol / L hydrochloric acid solution, mix it with the stirred tin chloride alcohol solution, and the molar ratio of antimony to tin is 0.15:1. After mixing, a small amount of precipitate precipitated in the solution, filtered off the precipitate, took the supernatant and added propylene oxide in an ice bath, the molar ratio of propylene oxide and tin was 11:1, and reacted in a sealed glass bottle for 20 minutes to obtain antimony Alcohol gel doped with tin dioxide. The obtained alcohol gel was soaked in ethano...

Embodiment 2

[0034]Dissolve tin tetrachloride pentahydrate in propanol to prepare a 0.5 mol / L tin tetrachloride alcohol solution; stir the tin tetrachloride alcohol solution in a 60°C water bath for 5 hours. Dissolve ammonium fluoride in water to prepare a 5mol / L ammonium fluoride aqueous solution. Stir the tin tetrachloride alcohol solution in a water bath at 60°C for 5 hours, and add the ammonium fluoride aqueous solution dropwise when the stirring starts, and the molar ratio of fluorine to tin is 0.5:1. Dissolve antimony trichloride in hydrochloric acid to prepare a 1mol / L hydrochloric acid solution, mix it with the stirred tin chloride alcohol solution, and the molar ratio of antimony to tin is 0.05:1. After mixing, a small amount of precipitate precipitated in the solution, filtered off the precipitate, took the supernatant and added propylene oxide in an ice bath, the molar ratio of propylene oxide and tin was 11:1, and reacted in a sealed glass bottle for 20 minutes to obtain antimo...

Embodiment 3

[0036] Dissolve tin tetrachloride pentahydrate in methanol to prepare 1mol / L tin tetrachloride alcohol solution; dissolve ammonium fluoride in water to prepare 10mol / L ammonium fluoride aqueous solution. Stir the tin tetrachloride alcohol solution in a water bath at 60°C for 5 hours, and add the ammonium fluoride aqueous solution dropwise when the stirring starts, and the molar ratio of fluorine to tin is 1:1. Dissolve antimony trichloride in hydrochloric acid to prepare a 2mol / L hydrochloric acid solution, mix it with the stirred tin chloride alcohol solution, and the molar ratio of antimony to tin is 0.2:1. After mixing, a small amount of precipitate precipitated in the solution, filtered off the precipitate, took the supernatant and added propylene oxide in an ice bath, the molar ratio of propylene oxide and tin was 25:1, and reacted in a sealed glass bottle for 20 minutes to obtain antimony Alcoholic gel doped with tin dioxide. The obtained alcohol gel was soaked in ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com