Method for preparing high carbon hydrocarbon through photocatalytic activation of biomethane

A biological methane and photocatalysis technology, applied in the chemical industry, can solve the problems of high energy consumption, high temperature coking and carbonization, and high temperature of high temperature dehydrogenation of methane, and achieve the effect of saving energy and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

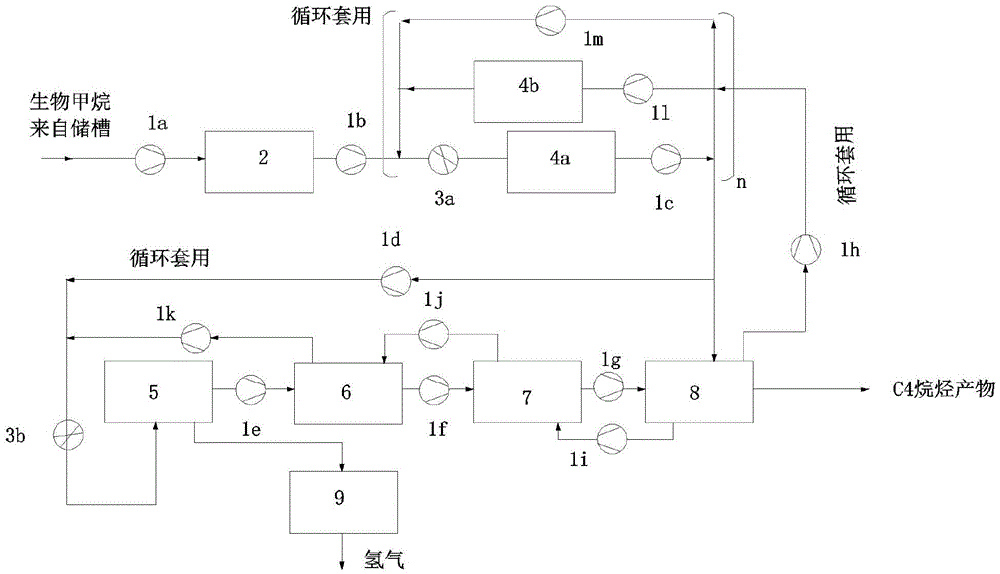

[0033] The biomethane from the storage tank is first pumped into the CO using air pump 1a 2 System 2 is removed, and the CO-free 2 Under 0.1MPa, the methane gas passes through the air pump 1b and the heat exchanger 3a, and passes into the multi-stage parallel photocatalytic activation reactor (4a, b, c, d, n), and the photocatalytic activation reactor has a built-in quartz glass tube, which is Made of quartz glass, the light source can be ultraviolet light, high-pressure mercury lamp, the wavelength is 200-400nm, the power of the photoreactor is 5w-10kw, and the built-in catalyst is proton acid H + , or the immobilization of protonic acid, heteropolyacid (such as phosphotungstic acid or phosphomolybdic acid), solid acid SiO 2 -Al 2 o 3 , B 2 o 3 -Al 2 o 3 And Pt, Sr, Ga, La, Ti, Ru, Zr, Ce, Mo, Zn, Cr, Co, Mn and W metals and their metal oxides, or loaded on the carrier, the carrier is γ-Al 2 o 3 , zeolite, molecular sieve, mesoporous silicon, TiO 2 , HZSM-5, HMCM-22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com