Reactive rectification method and device for separating ethylene glycol, propylene glycol and butylene glycol

A reactive distillation tower, ethylene glycol technology, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, preparation of organic compounds, etc., can solve the problem that propylene glycol and butanediol are not recycled, azeotroped or extracted The problems of high energy consumption and low separation energy consumption in rectification separation can achieve the effect of reducing energy consumption, less side reactions and better separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

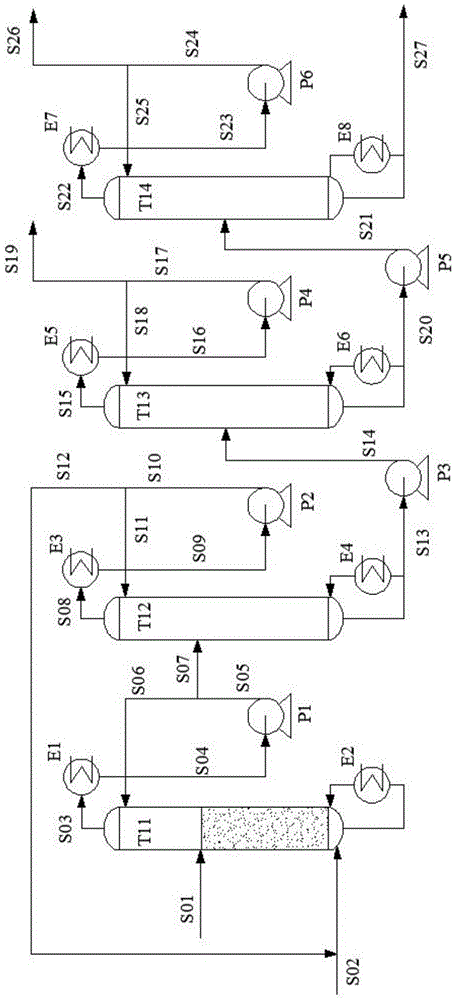

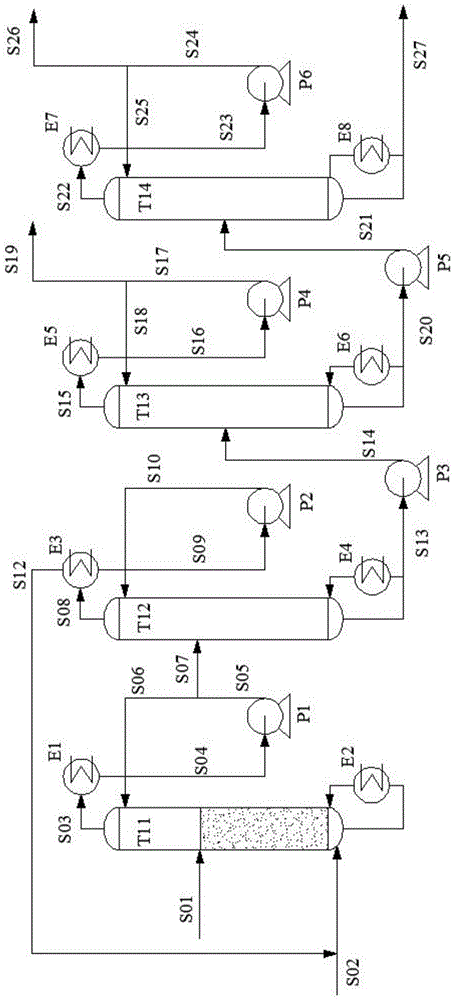

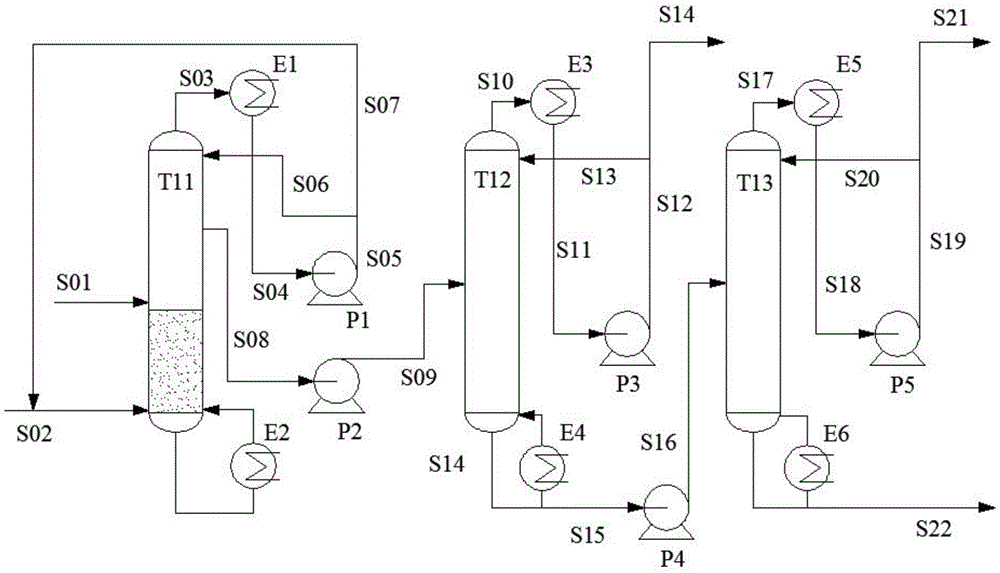

[0047] use figure 1 Shown flow process, raw material S01 (the mass fraction of ethylene glycol is 47.4%, the mass fraction of 1,2-propanediol is 21.2%, the mass fraction of 1,2-butanediol is 31.4%) and reactant acetaldehyde S02 Respectively enter from the upper part of the reaction section of the reactive distillation tower T11 and the bottom of the tower, the total number of theoretical plates of the reactive distillation tower is 21, the operating pressure is 0.5atm in terms of absolute pressure, the reflux ratio is 0.14, and the catalyst uses NKC-9 macroporous acidic cations Resin, the feeding amount of acetaldehyde and the total molar ratio of diol are 1.2:1, and the content of diol is controlled at the top of the tower. The stream S07 produced from the top of the reactive distillation tower enters the acetaldehyde recovery tower T12, the tower operating pressure is 2 atm in absolute pressure, the total number of theoretical plates is 20, the reflux ratio is 1.7, and unrea...

Embodiment 2

[0052] use figure 1 Shown flow process, raw material S01 (the mass fraction of ethylene glycol is 61.9%, the mass fraction of 1,2-propanediol is 22.3%, the mass fraction of 2,3-butanediol is 15.8%) and reactant acetaldehyde S02 Respectively enter from the upper part of the reaction section of the reactive distillation tower T11 and the bottom of the tower, the total number of theoretical plates of the reactive distillation tower is 21, the operating pressure is 0.5atm in terms of absolute pressure, the reflux ratio is 0.14, and the catalyst uses NKC-9 macroporous acidic cations Resin, the feeding amount of acetaldehyde and the total molar ratio of diol are 1.2:1, and the content of diol is controlled at the top of the tower. The stream S07 produced from the top of the reactive distillation tower enters the acetaldehyde recovery tower T12, the tower operating pressure is 2 atm in absolute pressure, the total number of theoretical plates is 20, the reflux ratio is 1.7, and unrea...

Embodiment 3

[0056] use figure 1The flow process shown, raw material S01 (the mass fraction of ethylene glycol is 84.7%, the mass fraction of 1,3-propanediol is 8.3%, the mass fraction of 1,3-butanediol is 7.0%) and reactant propionaldehyde S02 Respectively enter from the upper part of the reactive distillation column T11 reaction section and the bottom of the tower, the total number of theoretical plates of the reactive distillation column is 20, the operating pressure is 0.5atm in terms of absolute pressure, the reflux ratio is 0.12, and the catalyst uses NKC-9 macroporous acidic cationic resin , the feeding amount of propionaldehyde and the total molar ratio of diol are 1.5:1, and the content of diol is controlled at the top of the tower. The stream S07 produced from the top of the reactive distillation tower enters the propionaldehyde recovery tower T12. The operating pressure of the tower is 1.5 atm in terms of absolute pressure, the total number of theoretical plates is 22, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com