Small-size gold nanorod and preparation method and applications thereof

A gold nanorod, small size technology, applied in the field of nanomaterials, can solve the problems of gold nanorod size, aspect ratio and yield, which limit the large-scale preparation of gold nanorods, and poor dispersion of gold nanorods, etc. To achieve the effect of easy promotion, uniform size and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of small-sized gold nanorods, comprising the following steps:

[0052] Add 1mL chloroauric acid aqueous solution (5mM) to a 50mL test tube or beaker, then add 5mL cetyltrimethylammonium bromide aqueous solution (0.2M), after slight stirring, add 4.5mL ultrapure water, 500μL oleic acid Sodium aqueous solution (0.1M), stir slowly and evenly, add 250 μL silver nitrate aqueous solution (4mM), stir gently again, add 8 μL 37% concentrated hydrochloric acid, adjust the pH of the reaction system to 1, stir gently, add 56 μL ascorbic acid aqueous solution (0.1M), slightly After stirring, after the solution became colorless, 15 μL of frozen sodium borohydride aqueous solution (0.01M) was quickly added, and then stood in a 35°C incubator for 3 hours to obtain small-sized gold nanorods with a diameter of 6±1nm.

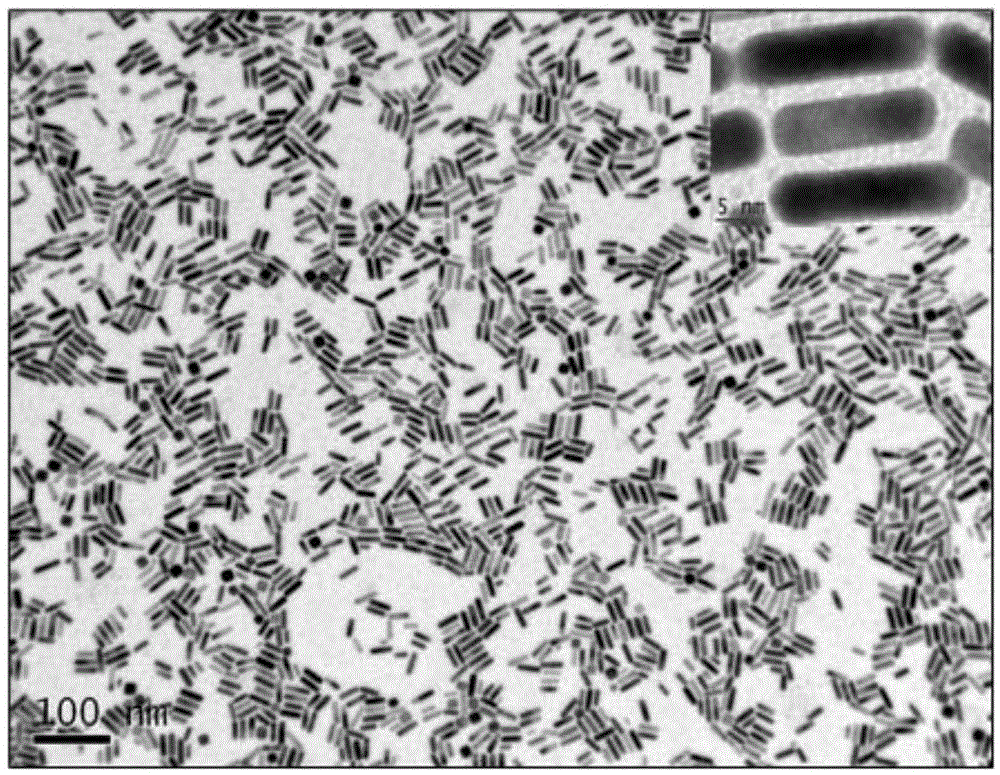

[0053] The test properties of the small-sized gold nanorods prepared above are as follows:

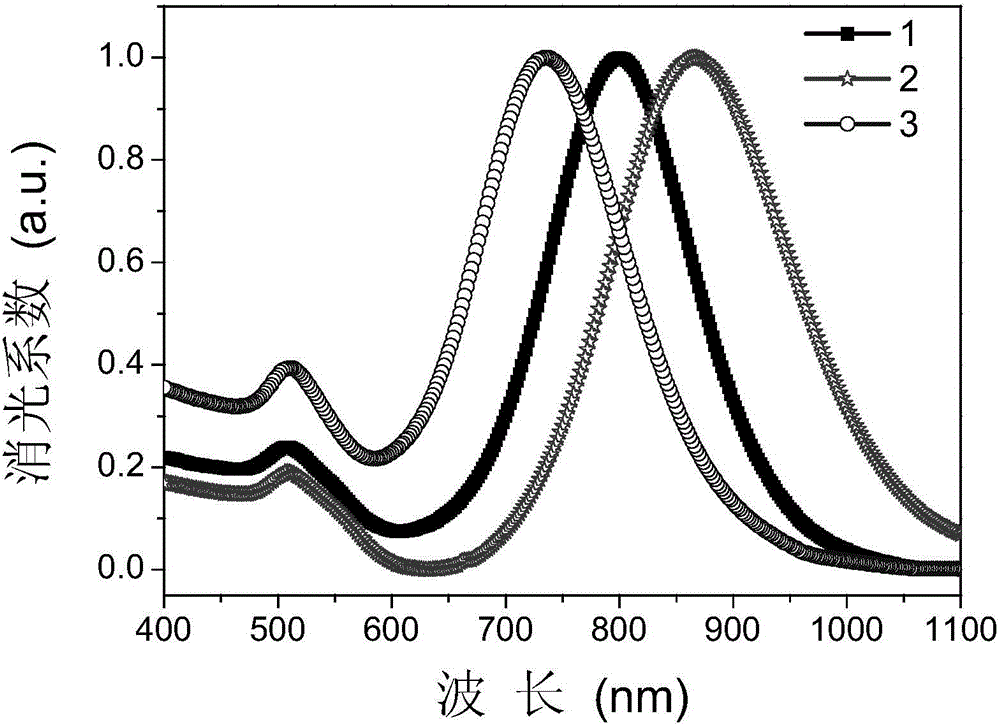

[0054] figure 1 It is the ultraviolet-visible-near-infr...

Embodiment 2

[0057] A preparation method of small-sized gold nanorods, comprising the following steps:

[0058] Add 500 μL chloroauric acid aqueous solution (5mM) to a 50mL test tube or beaker, then add 5mL cetyltrimethylammonium bromide aqueous solution (0.2M), after slight stirring, add 5mL ultrapure water, 100μL sodium oleate Aqueous solution (0.1M), stir slowly and evenly, add 200 μL silver nitrate aqueous solution (4mM), stir gently again, add 8 μL 37% concentrated hydrochloric acid, adjust the pH of the reaction system to 1, stir gently, add 56 μL ascorbic acid aqueous solution (0.1M), stir gently After the solution turned colorless, 15 μL of frozen sodium borohydride aqueous solution (0.01M) was quickly added, and then left to stand in a 35°C incubator for 3 hours to obtain small-sized gold nanorods with a diameter of 8±1nm.

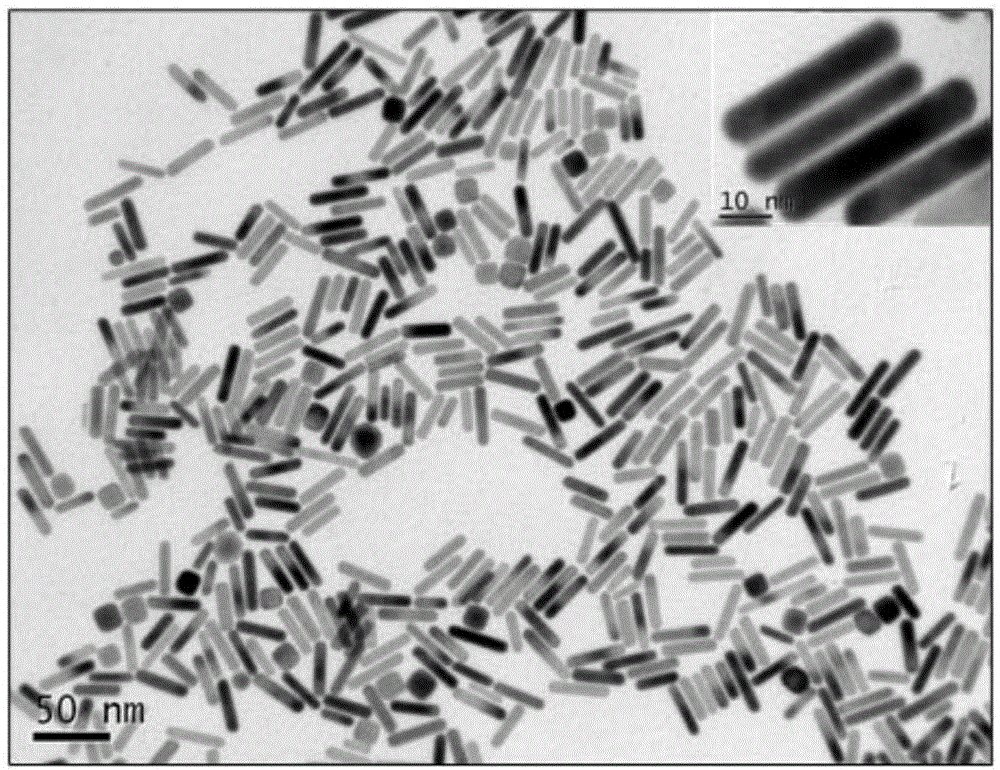

[0059] The test properties of the small-sized gold nanorods prepared above are as follows:

[0060] figure 1 It is the ultraviolet-visible-near-infrared abs...

Embodiment 3

[0063] A preparation method of small-sized gold nanorods, comprising the following steps:

[0064] Add 1mL chloroauric acid aqueous solution (5mM) into a 50mL test tube or beaker, take 5mL cetyltrimethylammonium bromide aqueous solution (0.2M) into it, stir gently, then add 4.5mL ultrapure water, 500μL oil Aqueous sodium nitrate solution (0.1M), stir slowly and evenly, add 150 μL silver nitrate solution (4 mM), stir slightly, add 8 μL 37% concentrated hydrochloric acid, adjust the pH of the reaction system to 1, stir slightly, add 56 μL aqueous ascorbic acid (0.1M), again Stir gently, and after the solution turns colorless, 15 μL of frozen sodium borohydride aqueous solution (0.01M) is quickly added immediately, and then left to stand in a 35°C incubator for 3 hours to obtain small-sized gold nanorods with a diameter of 5±1nm.

[0065] The test properties of the small-sized gold nanorods prepared above are as follows:

[0066] figure 1 It is the ultraviolet-visible-near-infr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com