Preparation method of antibacterial sepiolite powder

A technology of sepiolite and antibacterial powder, which is applied in the fields of botanical equipment and methods, chemicals for biological control, animal repellants, etc., can solve the problems of poor performance, inability to effectively control distribution, and insufficient whiteness of antibacterial materials. and other problems to achieve the effect of reducing prices, ensuring broad-spectrum antibacterial properties, and overcoming poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

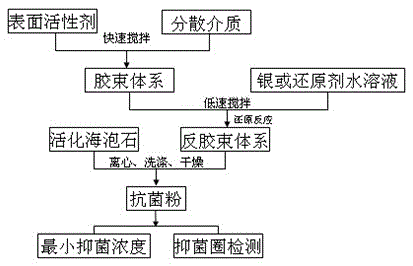

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of sepiolite antibacterial powder, comprising the steps of:

[0025] (1) Activation of sepiolite: add hydrochloric acid with a concentration of 0.75mol / L to sepiolite at a solid-to-liquid ratio of 1:15 for activation, and dry at 105°C for 12 hours to obtain activated sepiolite. BET characterization shows that the specific surface area of activated sepiolite is 194m 2 / g, pore diameter 49nm, pore volume 20cm 3 / g.

[0026] (2) Dissolve 1.332g of AOT in 40ml of cyclohexane, stir it at low speed to dissolve, divide it into A and B evenly, add 0.27ml, 0.06mol / L silver nitrate solution to A, add 0.27ml, 0.4mol to B / L hydrazine hydrate solution, after 40 minutes, the micellar solution A was added dropwise in the micellar solution B, and stirred at high speed for 1 hour to obtain the nano-silver micellar solution.

[0027] (3) Add the activated sepiolite in step (1) to the nano-silver micellar solution in step (2), stir thoroughly for 36 hours to ful...

Embodiment 2

[0032] A preparation method of sepiolite antibacterial powder, comprising the steps of:

[0033] (1) Sepiolite activation: Add sulfuric acid with a concentration of 0.5mol / L to the sepiolite according to the solid-to-liquid ratio of 1:10 for activation, and dry at 105°C for 12 hours to obtain activated sepiolite. BET characterization shows that the specific surface area of activated sepiolite is 204m 2 / g, pore diameter 50nm, pore volume 22cm 3 / g.

[0034] (2) Dissolve 1.776g of AOT in 40ml of cyclohexane, stir at a low speed to dissolve it, divide it into A and B evenly, add 0.27ml, 0.05mol / L silver nitrate solution to A, add 0.27ml, 0.4mol to B / L hydrazine hydrate solution, after 30 minutes, the micellar solution A was added dropwise in the micellar solution B, and stirred at high speed for 2 hours to obtain the nano-silver micellar solution.

[0035] (3) Add the activated sepiolite in step (1) to the nano-silver micellar solution in step (2), stir thoroughly for 36 h...

Embodiment 3

[0040] A preparation method of sepiolite antibacterial powder, comprising the steps of:

[0041] (1) Sepiolite activation: add hydrochloric acid with a concentration of 1mol / L to the sepiolite at a solid-to-liquid ratio of 1:20 for activation, and dry at 105°C for 12 hours to obtain activated sepiolite. BET characterization shows that the specific surface area of activated sepiolite is 180m 2 / g, pore diameter 49nm, pore volume 23cm 3 / g.

[0042] (2) Dissolve 0.888g CTAB in 40ml of n-octane, stir it at low speed to dissolve, and divide it into A and B evenly, add 0.27ml, 0.05mol / L silver citrate solution to A, add 0.27ml, 0.4 mol / L sodium borohydride solution, after 30 minutes, micellar solution A was added dropwise into micellar solution B, and stirred at high speed for 2 hours to obtain nano-silver micellar solution.

[0043] (3) Add the activated sepiolite in step (1) to the nano-silver micellar solution in step (2), stir thoroughly for 36 hours to fully combine the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com