Carbon nano tube immobilized laccase and application thereof

A technology for immobilizing laccase and carbon nanotubes, which is applied in the direction of immobilization on or in inorganic carriers, can solve the problems of leakage of conductive polymers, increased cost, and lack of universality of laccase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

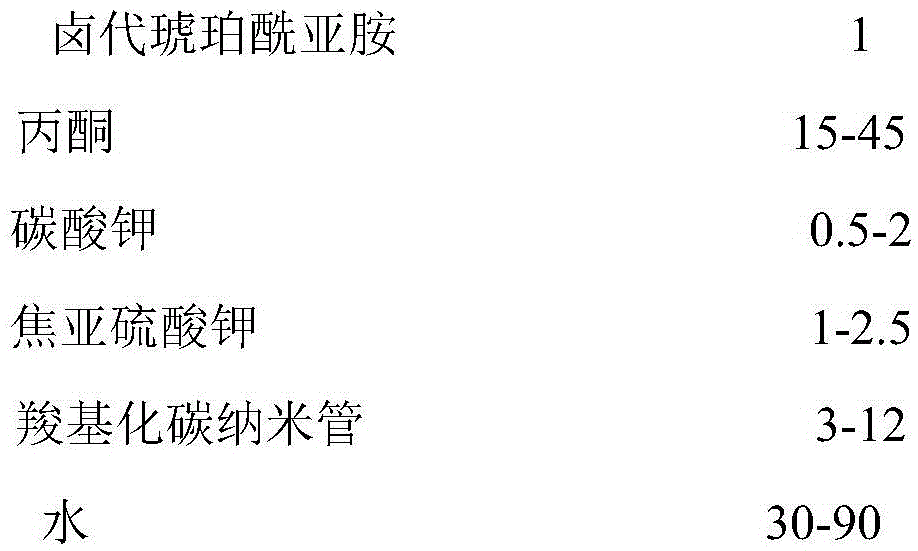

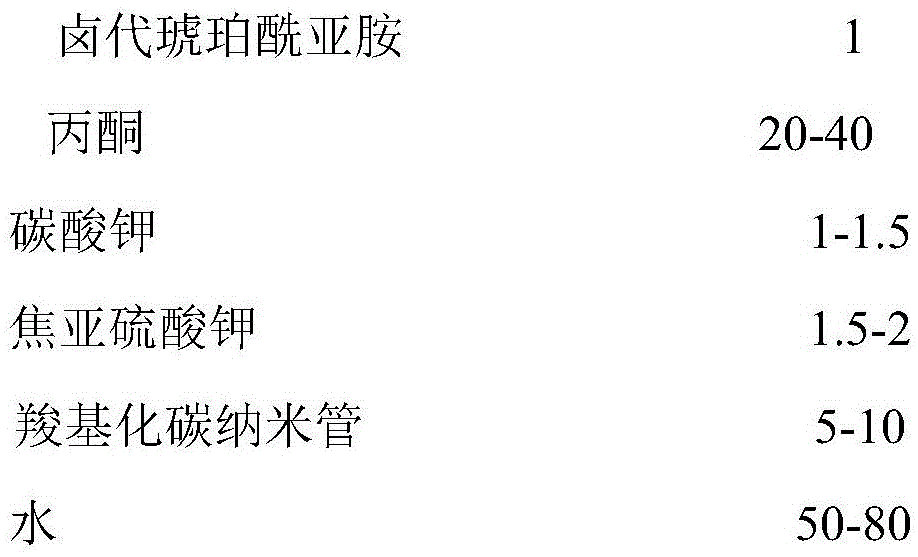

[0062] (1) At room temperature (about 25°C), dissolve 2g of halosuccinimide in 20g of acetone, mix 0.4g of potassium carbonate, 1g of potassium metabisulfite, and 2g of carboxylated carbon nanotubes in 20g of water until Completely dissolve the inorganic salt, mix the acetone solution with the aqueous solution, stir at 20°C, 300r / min for 20min, add 160g of chloroform-water mixture (2:1, v / v) for extraction and separation, and take the organic phase after standing for layers , washing the organic phase three times with deionized water whose volume is 1 / 2 of the organic phase layer, and removing chloroform by rotary evaporating the washed organic phase layer at 30° C., to obtain carbon nanotubes grafted with succinimide groups;

[0063] (2) At 30°C and 100r / min, in a reactor equipped with a reflux device, add 2g of N,N-di(carboxymethyl)-L-lysine hydrate, 4g of triethylamine and 40g of diethylamine Methylformamide, heated to reflux for 120min, under the conditions of 30°C and 300...

Embodiment 2

[0070] (1) At room temperature (about 25°C), dissolve 2g of halosuccinimide in 100g of acetone, mix 6g of potassium carbonate, 10g of potassium metabisulfite, and 30g of carboxylated carbon nanotubes in 200g of water until the inorganic Dissolve the salt completely, mix the acetone solution and the aqueous solution, stir at 30°C, 1000r / min for 30min, add 600g of chloroform-water mixture (2:1, v / v) for extraction and separation, and take the organic phase layer after standing and separating. Washing the organic phase 5 times with deionized water whose volume is 1 / 2 of the organic phase layer, and removing the chloroform by rotary evaporating the washed organic phase layer at 45° C., to obtain carbon nanotubes grafted with succinimide groups;

[0071] (2) At 50°C and 300r / min, in a reactor equipped with a reflux device, add 2g of N,N-di(carboxymethyl)-L-lysine hydrate, 12g of triethylamine and 120g of diethylamine Methylformamide, heated to reflux for 80min, under the conditions...

Embodiment 3

[0078] (1) At room temperature (about 25°C), dissolve 2g of halosuccinimide in 30g of acetone, mix 1g of potassium carbonate, 2g of potassium metabisulfite, and 6g of carboxylated carbon nanotubes in 60g of water until the inorganic Dissolve the salt completely, mix the acetone solution with the aqueous solution, stir at 40°C, 550r / min for 40min, add 200g of chloroform-water mixture (2:1, v / v) for extraction and separation, and take the organic phase layer after standing for stratification. The organic phase was washed 4 times with deionized water having a volume of 1 / 2 of the organic phase, and the washed organic phase was evaporated at 40° C. to remove chloroform to obtain succinimide grafted carbon nanotubes;

[0079] (2) Under the conditions of 35°C and 250r / min, in a reactor equipped with a reflux device, add 2g of N,N-di(carboxymethyl)-L-lysine hydrate, 6g of triethylamine and 60g of diethylamine Methylformamide was heated to reflux for 90 minutes. Under the conditions o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com