Method for preparing adenosine triphosphate with immobilized enzyme method

A technique for the reaction of adenosine triphosphate and adenosine triphosphate, which is applied in the direction of biochemical equipment and methods, fixed on/in organic carriers, enzymes, etc., can solve problems such as ineffective recycling, affecting application value, and rapid decline in enzyme activity, and achieves The effect of stable product quality, easy reaction and easy purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

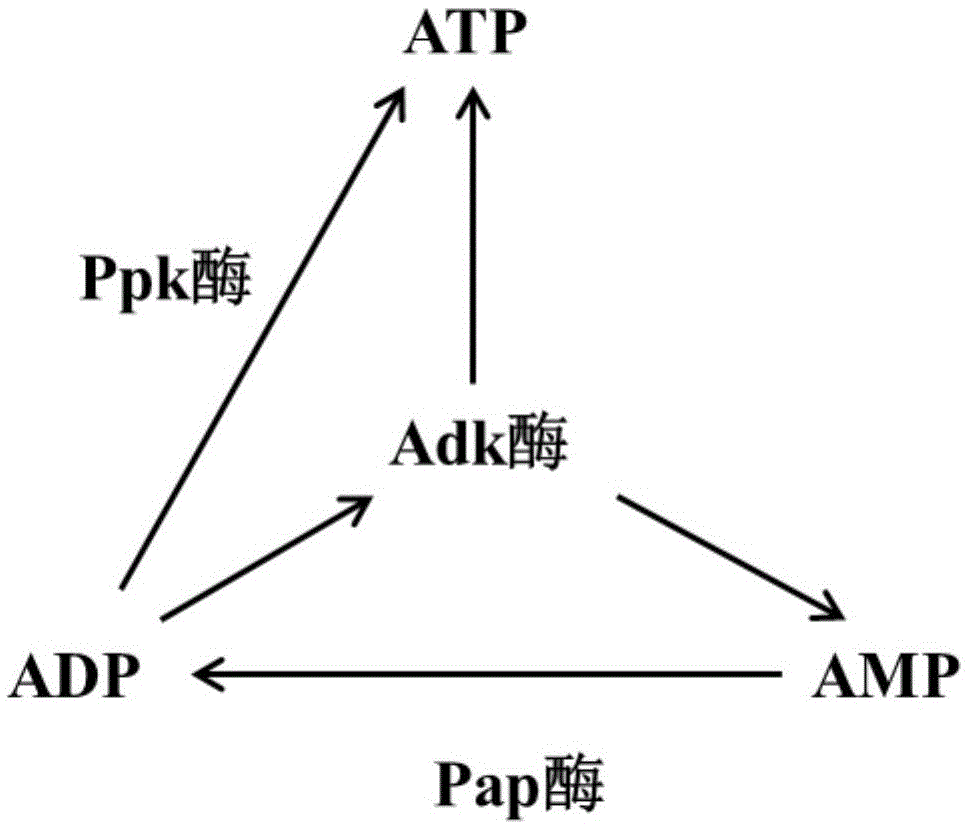

[0041] The preparation of embodiment 1Ppk, Adk and Pap enzyme

[0042] The Ppk, Adk and Pap enzymes in the method of the present invention can be obtained commercially, or are artificially modified enzymes having the same catalytic function.

[0043] The preparation process of Ppk, Adk and Pap enzyme is as follows:

[0044] According to the sequence of the following genes, three pairs of amplification primers were designed and synthesized by Zhongmei Taihe Biotechnology Co., Ltd. The primer sequences are as follows:

[0045] ppk sense primer: 5'-CCATATGGGTCAGGAAAAGCTATACATCG-3';

[0046] ppk antisense primer: 5'-CGGATCCTTTATTCAGGTTGTTCGAGTGATT-3';

[0047] adk sense primer: 5'-CCATATGCGTATCATTCTGCTTGGCGCTCCGG-3';

[0048] ADK antisense primer: 5'-CGGATCCTTAGCCGAGGATTTTTTTCCAGATC-3';

[0049] PAP sense primer: 5'-GCCATGGATACAGAAACGATCGCCAGTGCAG-3'; and

[0050] pap antisense primer: 5'-CGGATCCTTAATCCGTGTCGCGATCCGCTT-3';

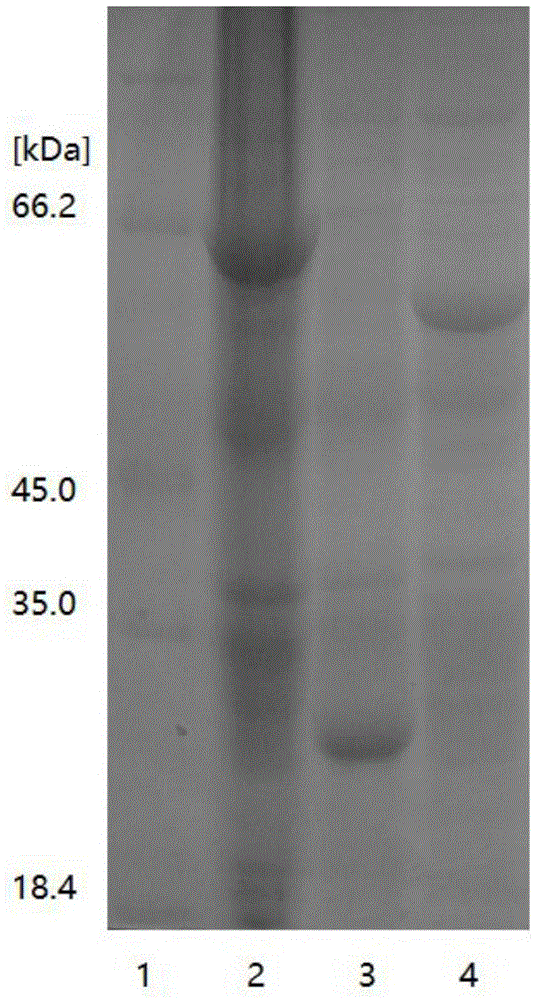

[0051] Extract the DNA of Escherichia coli (Escher...

Embodiment 2

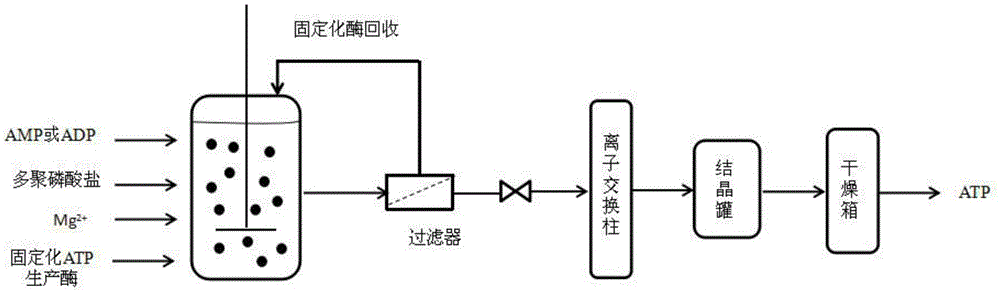

[0056] Example 2 Preparation of adenosine triphosphate by immobilized ATP production enzyme

[0057] Highly expressing Ppk and Pap strains were respectively prepared according to Example 1, and the bacterial cells were collected by centrifugation after the fermentation was completed. Take 2.0 kg of Pap-containing bacteria and 2.0 kg of Ppk-containing bacteria, mix and suspend them with 20 L of 0.1M pH7.5 Tris hydrochloric acid buffer, crush the bacteria with a high-pressure homogenizer, and collect the supernatant by centrifugation to obtain the ATP-producing enzyme.

[0058] Add 5 kg of amino-containing synthetic polymer carrier LX1000HA and 20 L of the above-mentioned ATP production enzyme into a constant temperature stirring reaction tank (the mass ratio of immobilized carrier to enzyme is 25:1), and stir at 150 rpm for 12 hours at 20°C. The carrier was collected by filtration, and washed twice with 0.02M pH 8.0 potassium phosphate buffer solution to obtain the immobilized ...

Embodiment 3

[0061] Example 3 Preparation of adenosine triphosphate by immobilized ATP production enzyme

[0062] Highly expressing Pap and Adk strains were respectively prepared according to Example 1, and the bacterial cells were collected by centrifugation after the fermentation was completed. Take 1.6 kg of Pap-containing bacteria and 0.4 g of Adk-containing bacteria, mix and suspend them in 20 L of phosphate buffer, crush the bacteria with a high-pressure homogenizer, and collect the supernatant by centrifugation to obtain an ATP-producing enzyme solution.

[0063] Add 4 kg of epoxy-containing polyacrylic acid carrier and 16 L of the above-mentioned ATP production enzyme solution into a constant temperature stirring reaction tank and mix (the ratio of immobilized carrier to enzyme protein is 40:1). Stir at 150 rpm for 5 h at 25°C. The carrier was collected by filtration and washed twice with 0.01 M pH 8.0 potassium phosphate buffer. The immobilized ATP-producing enzyme was placed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com