Alpha-linolenic acid microcapsule capable of being directly used for cooking and preparation method of alpha-linolenic acid microcapsule

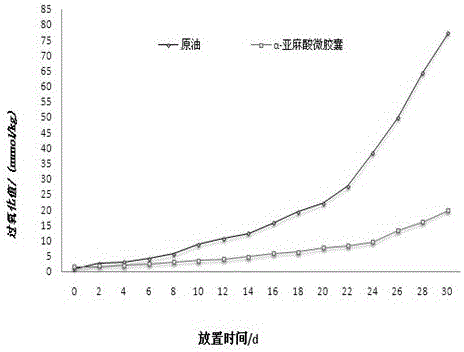

A technology of microcapsules and linolenic acid, which is applied in the field of oil production, can solve the problems of low shear resistance, viscosity stability, particle firmness, low embedding rate, and high surface oil content, so as to facilitate large-scale production and oil production. High embedding rate and long product shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033](1) Control the temperature of the heating medium at 45°C, first mix with 160g, 90% α-linolenic acid glyceride, 0.40g tert-butyl p-hydroxyanisole and 1.2g vitamin E, control the stirring speed at 280rmp, and wait for the mixture to be uniform Promptly get core material afterwards, spare. All operations are carried out under an inert gas environment;

[0034] (2) In an inert gas environment, put 300g of starch syrup, 350g of maltodextrin, 35g of sodium caseinate, 15g of monoglyceride, and 0.4g of sodium ascorbate into 1160g of water, control the temperature of the heating medium at 85°C, and heat and dissolve for 30 minutes After that, slowly cool down to 40°C, stir and mix well, and use it as a wall material for later use;

[0035] (3) In an inert gas environment, control the temperature of the heating medium within the temperature range of 30°C, put the core material prepared in step (1) into the aqueous phase liquid obtained in step (2), stir for 40 minutes, and then ...

Embodiment 2

[0039] (1) Control the temperature of the heating medium at 35°C, first mix 200g, 92% α-linolenic acid, 0.62g tert-butyl p-hydroxyanisole and 0.55g vitamin E, and control the stirring speed to 350rmp, and get the core after mixing evenly Material, spare. All operations are performed in an inert environment;

[0040] (2) Put 530g sodium starch octenyl succinate, 230g maltodextrin, 0.38g rosemary, 25g lecithin extract into 1035g water, control the temperature of the heating medium at 60°C, heat and dissolve for 35 minutes, then slowly cool down to 25 ℃, stir and mix well, set aside. All operations are carried out under an inert gas environment;

[0041] (3) Put the core material obtained in step (1) into the aqueous phase liquid obtained in step (2), control the temperature of the heating medium in the temperature range of 30°C, and stir for 28 minutes. Then, a shearing operation was performed at a speed of 3500 rpm for 15 minutes to obtain an emulsion. All operations are ca...

Embodiment 3

[0045] (1) Control the temperature of the heating medium at 40°C, first mix with 300g, 97% α-linolenic acid, and 1.36g of vitamin E, and control the stirring speed at 680rmp, and get the core material after mixing evenly, and set aside. All operations are performed in an inert environment;

[0046] (2) Put 216g of soybean protein isolate, 424g of modified starch, 220g of sodium caseinate, 14g of sucrose esters, and 0.82g of rosemary extract into 861g of water, control the temperature of the heating medium at 80°C, heat and dissolve for 35 minutes, then slowly cool down to 35°C, stir and mix well, set aside. All operations are carried out under an inert gas environment;

[0047] (3) Put the core material obtained in step (1) into the aqueous phase liquid obtained in step (2), control the temperature of the heating medium in the temperature range of 30° C., and stir for 40 minutes. Then, a shearing operation was performed at a speed of 5000 rpm for 5 minutes to obtain an emuls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com