Copper oxide-zinc oxide composite catalyst, preparation method and application

A composite catalyst, copper oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of unsatisfactory catalytic performance, uneven mixing, process flow Long and other problems, to achieve the effects of controllable copper and zinc components, small particles and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

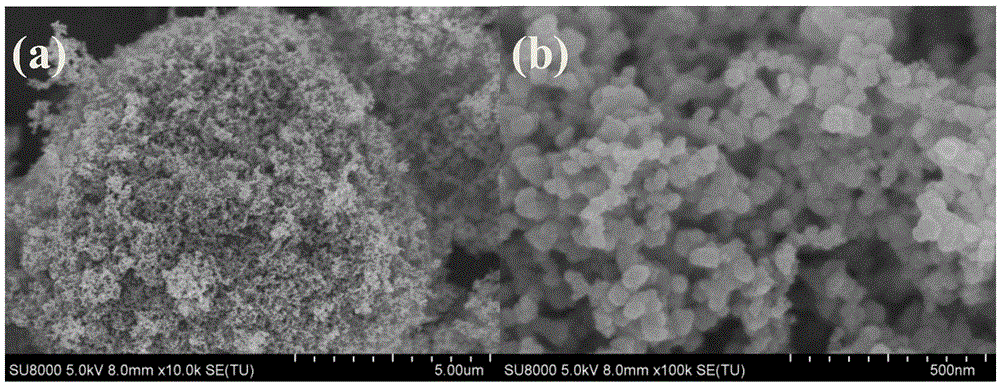

[0069] Catalyst preparation:

[0070] (1) Configure copper-zinc ion solution (n Cu 2+ is 0.025mol and n Cu 2+ :n Zn 2+ =10:1) 100mL, the solvent is a pure aqueous solution, the copper ions are derived from copper acetate, and the zinc ions are derived from zinc acetate;

[0071] (2) 4.4g carbon black (50nm) is joined in the copper zinc ion solution of step (1), makes in the solution, the mass ratio of carbon black and catalyst active ingredient (copper oxide and zinc oxide) is 2:1, stirs 4h, impregnated to obtain a carbon black template impregnated with copper-zinc ion solution;

[0072] (3) drying the carbon black template impregnated with the copper-zinc ion solution obtained in step (2) at 60° C. for 4 hours to obtain a carbon black template impregnated with copper-zinc ions;

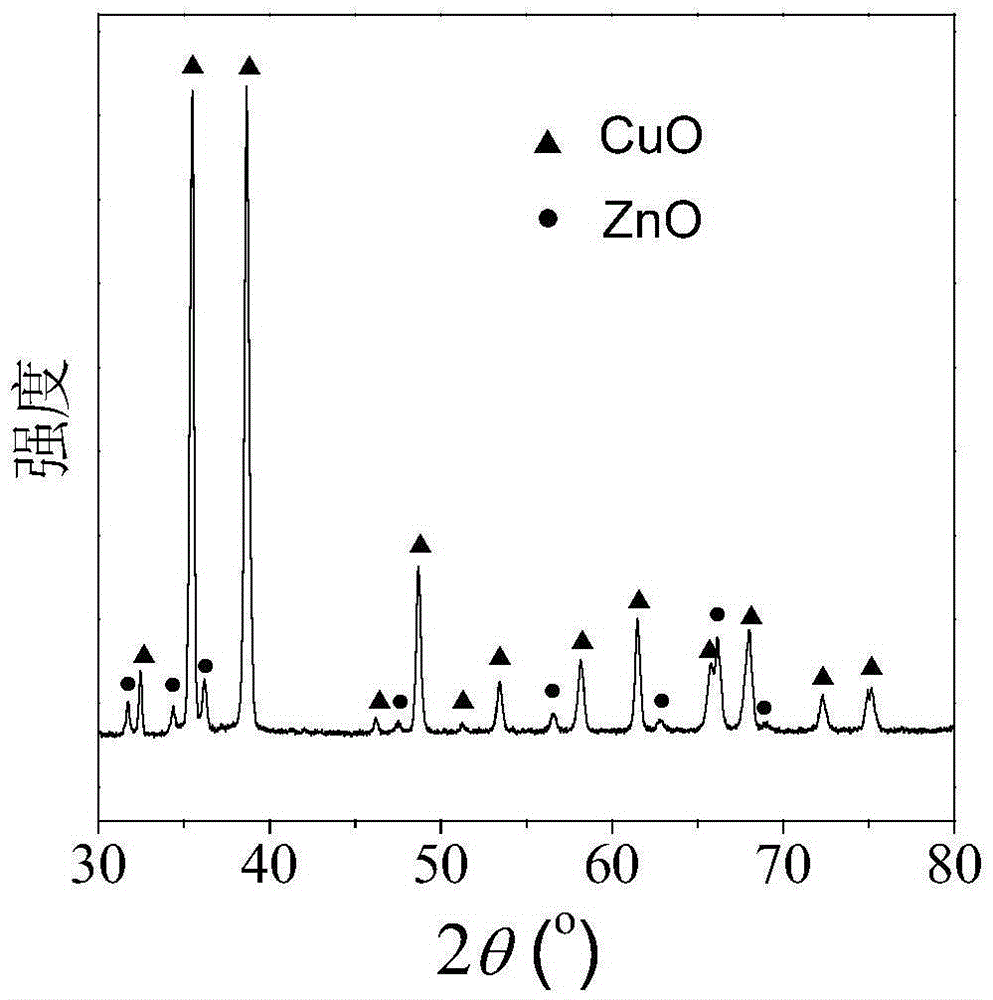

[0073] (4) Calcining the carbon black template impregnated with copper-zinc ions obtained in step (3) at 500° C. for 4 h in an air atmosphere to obtain a copper oxide-zinc oxide composite cata...

Embodiment 2

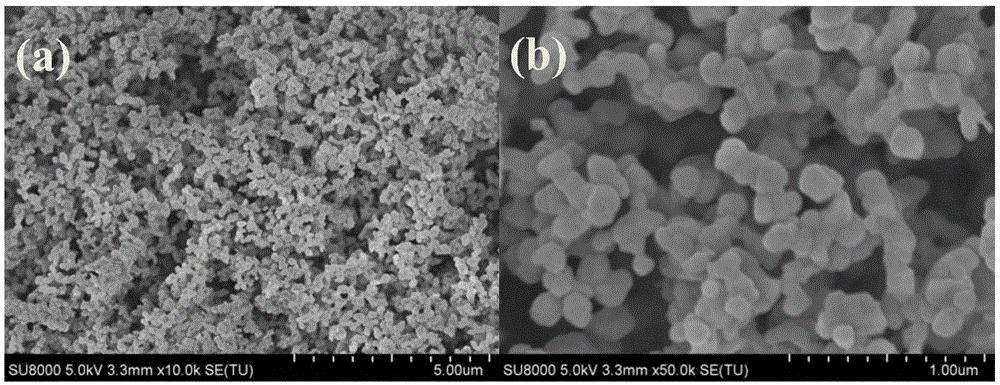

[0083] Catalyst preparation:

[0084] (1) Configure copper-zinc ion solution (n Cu 2+ =0.030mol and n Cu 2+ :n Zn 2+ =10:1) 200mL, the solvent is an aqueous alcohol solution (volume ratio of ethanol to water is 0.2:1), copper ions are derived from copper nitrate, and zinc ions are derived from zinc nitrate;

[0085](2) 13.2g of carbon black (60nm) was added to the solution containing copper and zinc ions, so that the mass ratio of carbon black to catalyst active ingredients (copper oxide and zinc oxide) was 5:1, stirred for 8h, and impregnated. A carbon black template impregnated with a copper-zinc ion solution is obtained;

[0086] (3) drying the carbon black template impregnated with the copper-zinc ion solution obtained in step (2) at 80° C. for 24 hours to obtain a carbon black template impregnated with copper-zinc ions;

[0087] (4) Calcining the carbon black template impregnated with copper-zinc ions obtained in step (3) at 750° C. for 24 hours in an air atmospher...

Embodiment 3

[0094] Catalyst preparation:

[0095] (1) configuration of copper-zinc ammonium complex solution (n Cu2+ =0.040mol and n Cu 2+ :n Zn 2+ =10:1) 100mL, the solvent is an aqueous ethanol solution (alcohol-water ratio is 0.4:1), the copper ions are derived from ammonia-impregnated copper powder, and the zinc ions are derived from ammonia-impregnated zinc oxide;

[0096] (2) 10.6g common nano carbon black (70nm) is joined in the ammonia complex solution of copper zinc, and in described solution, the mass ratio of carbon black and catalyst active ingredient (copper oxide and zinc oxide) is 3: 1. Stir for 16 hours and impregnate to obtain a carbon black template impregnated with a copper-zinc ion solution;

[0097] (3) drying the carbon black template impregnated with the copper-zinc ion solution obtained in step (2) at 100° C. for 16 hours to obtain a carbon black template impregnated with copper-zinc ions;

[0098] (4) Calcining the carbon black template impregnated with copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com