Anion exchange membrane containing pyridine skeleton as well as preparation method and application of anion exchange membrane

An anion-exchange membrane and pyridine technology, applied in ion-exchange water/sewage treatment, chemical instruments and methods, fuel cells, etc., can solve problems such as poor chemical stability and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

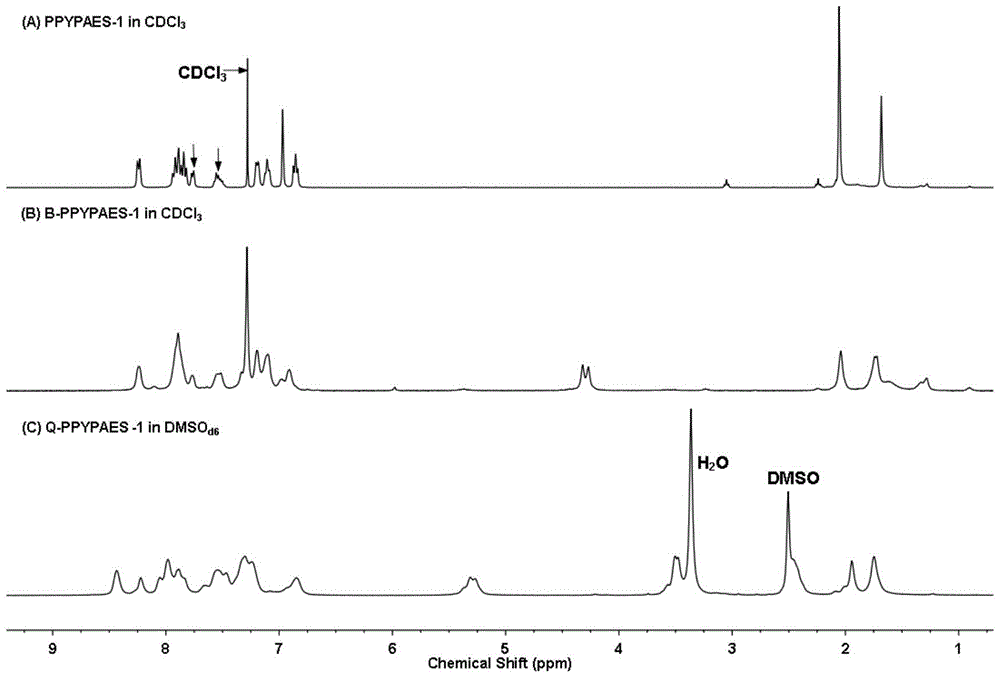

Embodiment 1

[0069] 5mmol of pyridine-containing bisphenol monomer (formula 13), 5mmol of dihalogenated monomer A (formula 22), 5mmol of bisphenol monomer B (formula 19), 5mmol of dihalogenated monomer C (Formula 22), 25mmol of potassium carbonate, 30ml of toluene and 50ml of sulfolane are added to a 250ml four-necked flask equipped with a water separator, a thermometer, an agitator and a nitrogen inlet and outlet, and the temperature is first raised to 140° C. for 3 hours, and then Raise the temperature to 210°C for 3 hours, pour the polymer solution into ethanol to obtain a precipitate, wash it repeatedly with ethanol and deionized water three times, and dry it in vacuum at 80°C for 48 hours to obtain polyarylether polymer resin PPYPAES-1; The product resin was dissolved in 20ml (31.86g) of 1,1,2,2-tetrachloroethane, added 1.27g of N-bromosuccinimide and 0.086g of benzoyl peroxide, and reacted at 85°C Bromination reaction was carried out for 5 hours, cooled to room temperature, poured in...

Embodiment 2

[0074] 5mmol of bisphenol monomer containing pyridine group (formula 14), 5mmol of dihalogenated aromatic monomer A (formula 23), 5mmol of bisphenol monomer B (formula 20), 5mmol of dihalogenated monomer C (formula 23), the sodium carbonate of 25mmol, the toluene of 20ml and the N,N-dimethylacetamide of 50ml join in the 250ml four-neck flask that water trap, thermometer, stirrer and nitrogen inlet and outlet are housed, First raise the temperature to 140°C for 3 hours, continue to raise the temperature to 165°C for 12 hours, pour the polymer solution into ethanol to obtain polymer precipitation, wash with ethanol and deionized water repeatedly for 3 times, and vacuum dry at 80°C for 48 hours to obtain pyridine-containing Skeleton polymer resin PPYPAES-2; dissolve 1g of polymer resin in 20ml (31.86g) of 1,1,2,2-tetrachloroethane, add 1.27g of N-bromosuccinimide and 0.086 g of benzoyl peroxide, reacted at 85°C for 5h for bromination reaction, cooled to room temperature, poured i...

Embodiment 3

[0078] 5mmol of novel bisphenol monomer containing pyridine group (formula 15), 5mmol of dihalogenated aromatic monomer A (formula 24), 5mmol of bisphenol monomer B (formula 21), 5mmol of dihalogenated mono Body C (formula 24), 25mmol of cesium carbonate, 25ml of toluene and 50ml of N,N-dimethylformamide were added to a 250ml four-necked flask equipped with a water separator, a thermometer, a stirrer and a nitrogen inlet and outlet , first raised the temperature to 140°C for 3 hours, then continued to heat up to 150°C for 20 hours, poured the polymer solution into ethanol to obtain a polymer precipitate, repeatedly washed with ethanol and deionized water for 3 times, dried in vacuum at 80°C for 48 hours, and obtained Pyridine skeleton polymer resin PPYPAES-3; dissolve 1g of polymer resin in 20ml (24.70g) of 1,2-dichloroethane, add 1.27g of N-bromosuccinimide and 0.0583g of dichlorosuccinimide Azodiisobutyronitrile, reacted at 80°C for 6h for bromination reaction, cooled to roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com