A kind of aspergillus oryzae and application thereof

A kind of Aspergillus oryzae, application technology, applied in Aspergillus oryzae and its application field, can solve the problems of lack of high-yield strains, poor stability, high production cost, etc., achieve good application prospects, stable enzyme activity, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

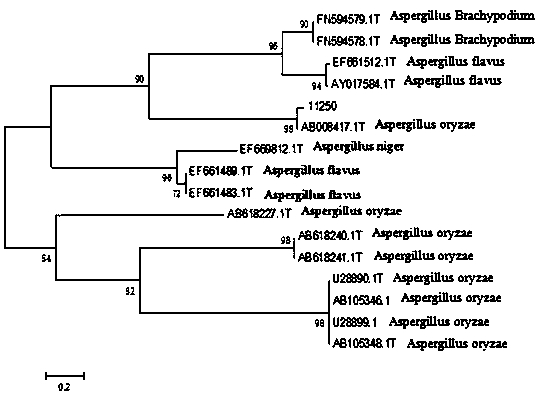

[0055] Example 1 Aspergillus oryzae 11250 screening isolation and identification

[0056] 1. Aspergillus oryzae ( Aspergillus oryzae ) 11250 screening isolate

[0057] Weigh 2g of soil samples collected from all over the country and shake them for 30min in a 100mL Erlenmeyer flask filled with 18mL of sterilized normal saline. It is best to put a little glass beads in the Erlenmeyer flask. Then diluted with sterile water to a volume concentration of 1 × 10 -3 , 1×10 -4 For two gradient dilutions, pipette 100 μL dilutions with sterilized pipette tips and apply to the pre-prepared and sterilized selective plate medium (the composition of the selective plate medium is (g / L): MgSO 4 0.5, KH 2 PO 4 1.5, CaCl 2 0.1, (NH 4 ) 2 SO 4 1.5, KCl 0.5, KNO 3 1.5, yeast extract 2, orange peel powder 7.5, agar 20, water balance), cultivated at 30°C for 48-96h. Separate the single colony by streaking from the selective plate medium, and check the purity of the strain by microscopi...

Embodiment 2

[0083] Embodiment 2 The preparation of the liquid fermented liquid of Aspergillus oryzae 11250 containing naringinase

[0084] (1) Slant culture: Aspergillus oryzae 11250 was inoculated on the slant medium and cultured at 40°C for 48 hours to obtain the slant strain. The slant medium used is: MgSO 4 0.5, KH 2 PO 4 1.5, CaCl 2 0.1, (NH 4 ) 2 SO 4 1.5, KCl 0.5, KNO31.5, yeast extract 2, orange peel powder 15, agar 20, water balance, (g / L); pH 6.0, 1×10 5 Pa sterilized for 20 min.

[0085] (2) Liquid shake flask fermentation: Inoculate the obtained slant strain into the liquid shake flask medium with an inoculation amount of 0.2% (V / V), culture at 30°C, shaker speed 180r / min, and culture keep The time is 96h; the fermentation broth is obtained. Liquid shake flask medium is: maltose concentration 2, beef extract peptone 3, MgSO 4 0.5, KH 2 PO 4 1.5, CaCl 2 0.1, (NH 4 ) 2 SO 4 1.5, KCl 0.5, KNO 3 1.5, yeast extract 2, orange peel powder 7.5, water balance...

Embodiment 3

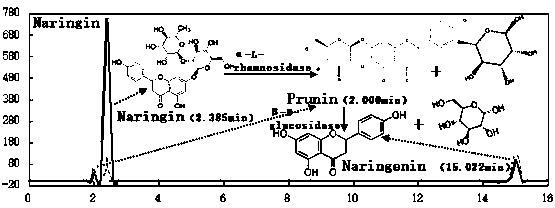

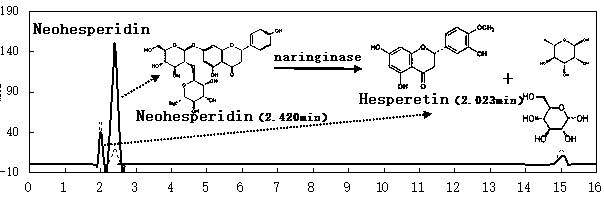

[0090] Embodiment 3 Aspergillus oryzae 11250 liquid fermentation produces naringinase

[0091] Centrifugal separation: centrifuge the fermentation broth, and take the supernatant; the centrifugation speed is 8000rpm, and the centrifugation time is 10min.

[0092] The supernatant ammonium sulfate is graded and precipitated: add ammonium sulfate to the supernatant (ammonium sulfate is an analytically pure ammonium sulfate reagent) to make the mass volume concentration 50%, filter to remove the resulting precipitate, and then continue to add ammonium sulfate to the filtrate , until its mass volume concentration is 50%-70%, and the precipitate containing naringinase is obtained by filtration. The mass volume concentration means: the mass (g) of ammonium sulfate contained in each mL supernatant.

[0093] Elution: After the naringinase-containing precipitate is eluted with 0~1mol / L NaCl (the optimal concentration is 0.6mol / L), the naringinase eluate is collected.

[0094] Q Sephar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com