Preparation of chitosan-based adsorption agent and application of chitosan-based adsorption agent to heavy metal ion wastewater treatment

A technology for heavy metal ions and chitosan, which is applied in the fields of adsorption water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

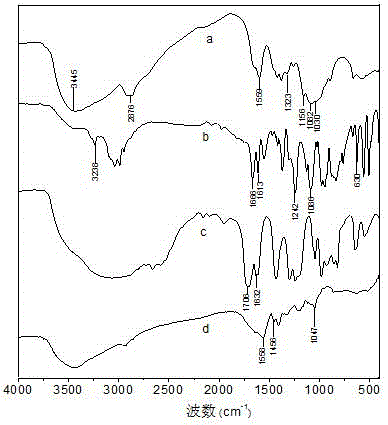

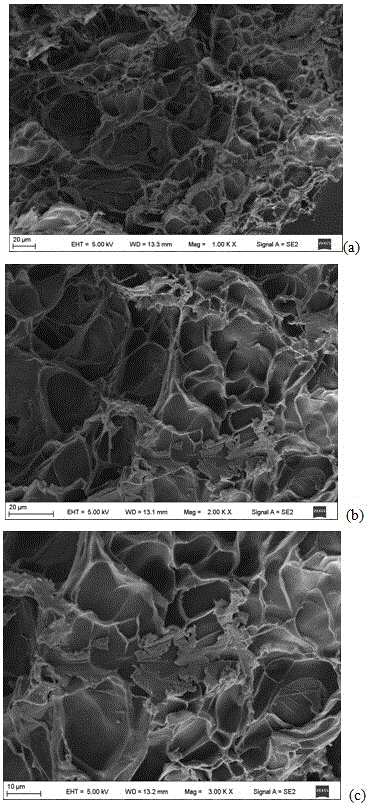

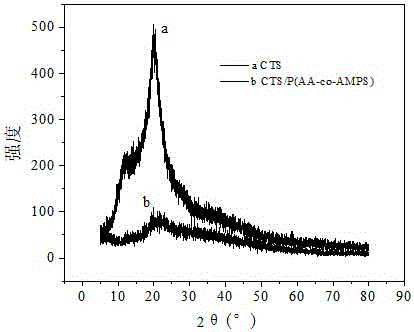

Embodiment 1

[0052] Add 0.5gCTS and 40mL distilled water into a 250mL three-neck flask, stir at 75°C for about 5min to fully disperse; add 0.06gMBA, 8mLAA and 2gAMPS after cooling down to room temperature, stir for 10min (stirring speed 100r / min); turn on the power , using GDEP at 480V, 85mA glow discharge for 3min; stop the discharge, continue to stir in an oil bath at 75°C for 4h, then cool to obtain a jelly-like gel; cut it to a diameter of 2~5mm, neutralize it with NaOH to make the neutralization degree reach 60%, wash with water to remove unreacted raw materials, place in a vacuum oven, dry at 65°C, and grind to obtain CTS / P (AA-co-AMPS) adsorbent.

[0053] Adsorption performance: The adsorption reaches equilibrium in 180 minutes. For solution (300mg / L) Cd 2+ 、Cu 2+ 、Ni 2+ , Pb 2+ The adsorption capacity of each is 367, 297, 170, 787mg / g.

Embodiment 2

[0055] Add 0.9gCTS and 40mL distilled water into a 250mL three-neck flask, stir at 75°C for about 5min to fully disperse; add 0.04gMBA, 8mLAA and 2gAMPS after cooling down to room temperature, stir for 10min to fully dissolve; then turn on the power, use GDEP was glow-discharged at 450V and 57mA for 5min; stop the discharge, continue to stir in an oil bath at 75°C for 4h, then cool to obtain a jelly-like gel; cut it to a diameter of 2-5mm, and neutralize it with NaOH to reach 70%; washed with water to remove unreacted raw materials, dried in a vacuum oven at 65°C, and ground to obtain CTS / P (AA-co-AMPS) adsorbent.

[0056] Adsorption performance: The adsorption reaches equilibrium in 180 minutes, and the Cd in the solution (300mg / L) 2+ 、Cu 2+ 、Ni 2+ , Pb 2+ The adsorption capacity of each is 330, 292, 183, 780mg / g.

Embodiment 3

[0058] Add 0.9gCTS and 40mL distilled water into a 250mL three-neck flask, stir at 75°C for about 5min to fully disperse; add 0.06gMBA, 8mLAA and 2gAMPS and stir for 10min to fully dissolve; turn on the power, use GDEP to Glow discharge at 430V, 45mA for 2min; stop the discharge, continue to stir in an oil bath at 75°C for 4h, then cool to obtain a jelly-like gel; cut into pieces to a diameter of 2~5mm, neutralize with NaOH to reach a neutralization degree of 90% ; Wash with water to remove unreacted raw materials, dry in a vacuum oven at 65° C., and grind to obtain CTS / P (AA-co-AMPS) adsorbent.

[0059] Adsorption performance: The adsorption reaches equilibrium in 180 minutes, and the (300mg / L) Cd in the solution 2+ 、Cu 2+ 、Ni 2+ , Pb 2+ The adsorption capacity of each is 383, 280, 360, 797mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com