High-performance perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve problems such as solar cell device performance and stability to be improved, and achieve the effect of improving device performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

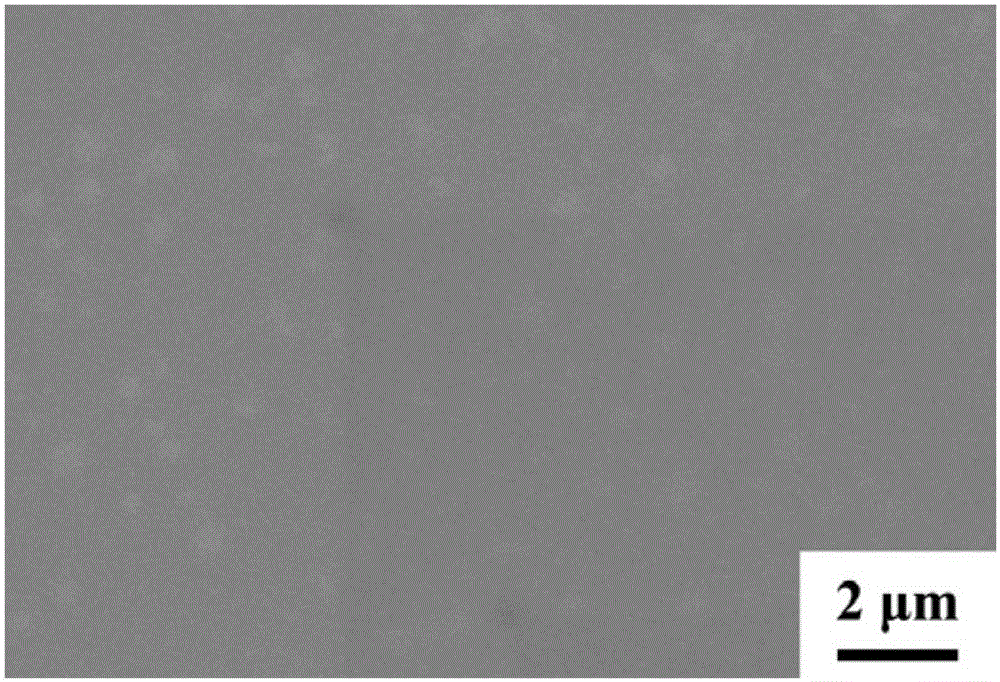

[0038] The indium tin oxide was cleaned with detergent, sonicated in acetone and ethanol, and then dried with nitrogen to obtain the indium tin oxide electrode layer ITO. The indium tin oxide electrode layer ITO was treated with ultraviolet ozone plasma for 15 minutes, the PEDOT:PSS film was spin-coated at 4500 rpm / 40s by spin coating, and annealed at 120°C for 10 minutes to obtain the hole transport layer PEDOT:PSS. Graphene oxide was prepared from flake expanded graphite by the Hummer method as raw material. According to graphene oxide GO and ammonia solution NH 3 The molar ratio is 1:0 to form an ammonia-modified graphene oxide aqueous solution. The ammonia-modified graphene oxide aqueous solution was spin-coated on the hole transport layer PEDOT:PSS, and annealed at 120°C for 10 min to obtain the ammonia-modified graphene oxide layer GO:NH 3 . In the ammonia-modified graphene oxide layer GO:NH 3 Spin-coat a 30% perovskite precursor solution at a speed of 4000 rpm / 40s, ...

Embodiment 2

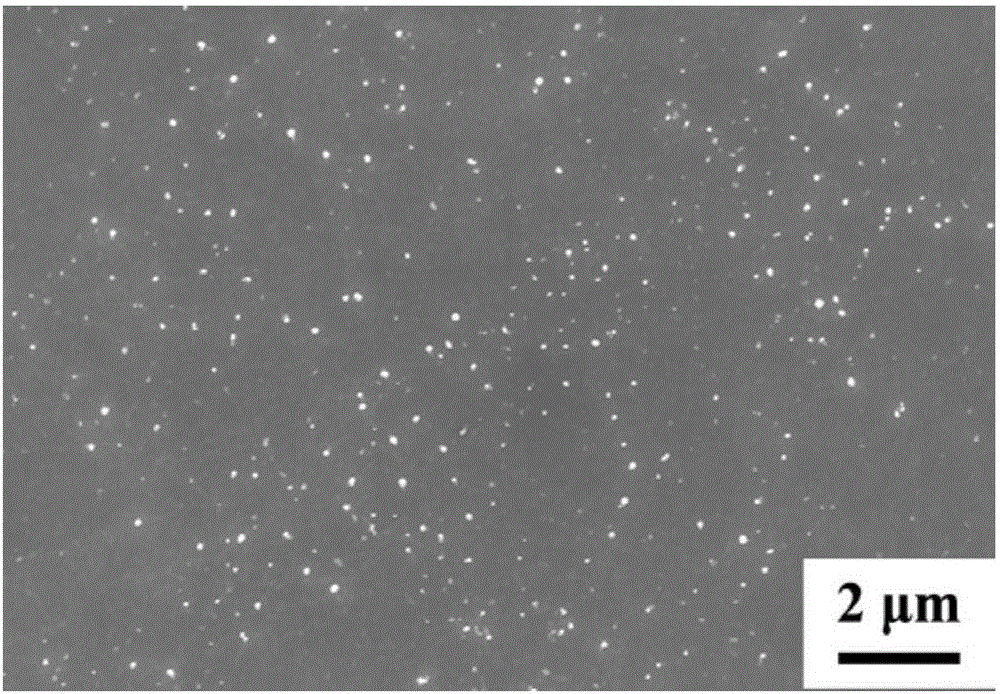

[0041] The perovskite solar cell was prepared with reference to the method of Example 1, the difference was that the graphene oxide GO and the ammonia solution NH in the mixed solution 3 The molar ratio is 1:0.3.

[0042] Test the device performance of perovskite solar cells, the conversion efficiency is 16.11%, the open circuit voltage is 1.03V, and the short circuit current density is 22.06mA / cm 2 , with a fill factor of 71%, such as Figure 4 shown.

Embodiment 3

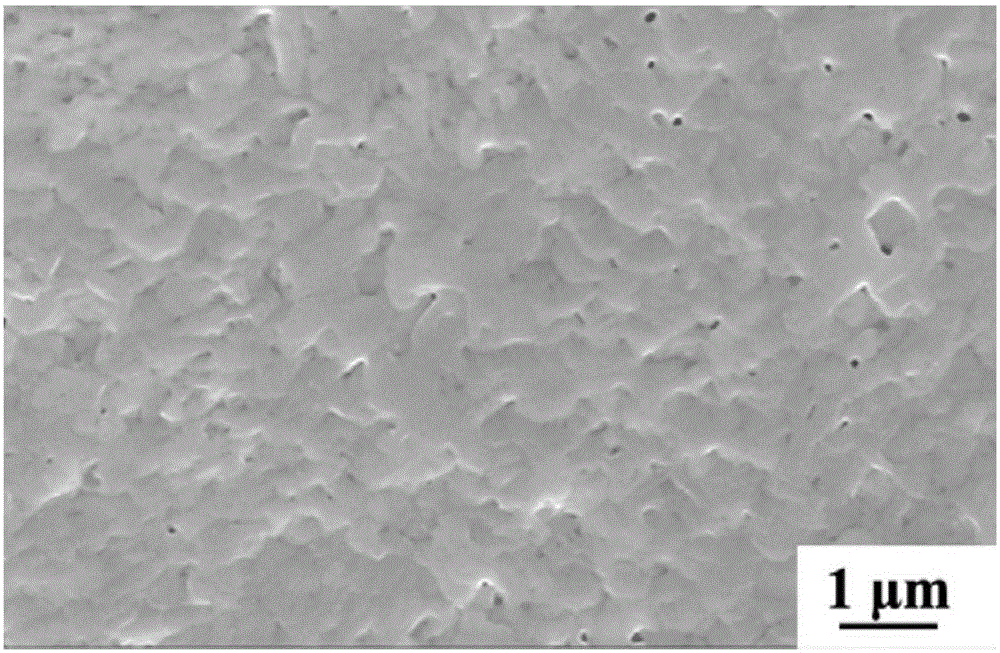

[0044] The perovskite solar cell was prepared with reference to the method of Example 1, the difference was that the graphene oxide GO and the ammonia solution NH in the mixed solution 3 The molar ratio is 1:0.4.

[0045] Test the device performance of perovskite solar cells, the conversion efficiency is 14.49%, the open circuit voltage is 1.01V, and the short circuit current density is 20.90mA / cm 2 , the fill factor is 69%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com