Macromolecular composite membrane material with photocatalysis activity and preparation method thereof

A technology of photocatalytic activity and polymers, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. Particles cannot be excited by light sources, etc., and achieve the effect of simple preparation method, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

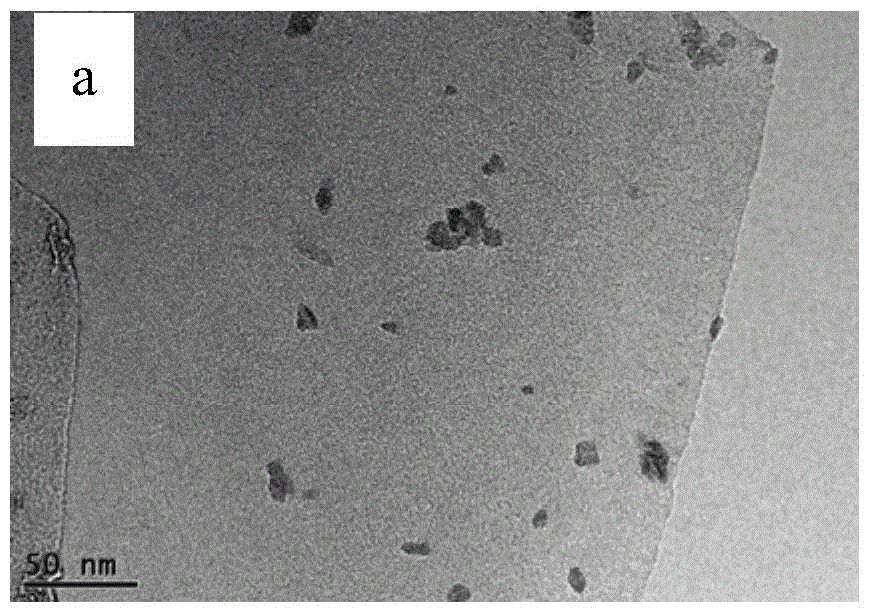

[0043] (1) TiO 2 -Preparation of graphene composite materials

[0044] Get 1g graphene oxide (50m 2 / g) and 5mL of deionized water and 250mL of absolute ethanol were mixed, ultrasonicated for 15 minutes to obtain a brown-black suspension solution, and then under strong stirring conditions, 2.5g of butyl titanate was added dropwise to the suspension and the temperature was raised to 80°C reaction. After reacting for 5 hours, the reaction liquid was cooled to room temperature, filtered, and washed until the washing liquid was close to neutral to obtain TiO 2 - Graphene oxide nanocomposites, the TiO 2 -Graphene oxide nanocomposites suspended in 200mL of purified water to obtain TiO 2 - Suspension system of graphene oxide nanomaterials.

[0045] Add the above to include TiO 2 -All the suspension system of graphene oxide nanomaterials was moved into the autoclave, and then 1g of ascorbic acid was added. After sealing it well, it was placed in a high-temperature blast drying o...

Embodiment 2

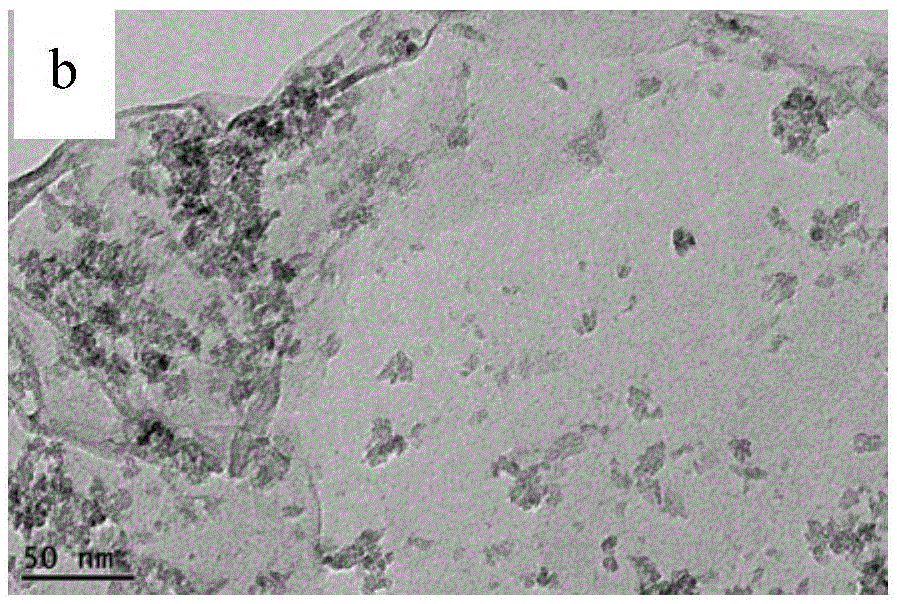

[0054] (1) TiO 2 -Preparation of graphene composite materials

[0055] Take 1g of graphene oxide, 5mL of deionized water and 250mL of absolute ethanol and mix them with ultrasound for 15 minutes to obtain a brown-black suspension solution. Then, under strong stirring conditions, add 5g of butyl titanate dropwise into the suspension and heat up to 80 ℃ reaction. After reacting for 5 hours, the reaction liquid was cooled to room temperature, filtered, and washed until the washing liquid was close to neutral to obtain TiO 2 - Graphene oxide nanocomposites, the TiO 2 -Graphene oxide nanocomposites suspended in 200mL of purified water to obtain TiO 2 - Suspension system of graphene oxide nanomaterials.

[0056] Add the above to include TiO 2 -The suspension system of graphene oxide nanomaterials is all moved into the autoclave, and then 1g of ascorbic acid is added. After sealing it well, it is placed in a high-temperature blast drying oven, placed at 160°C for 24 hours, and t...

Embodiment 3

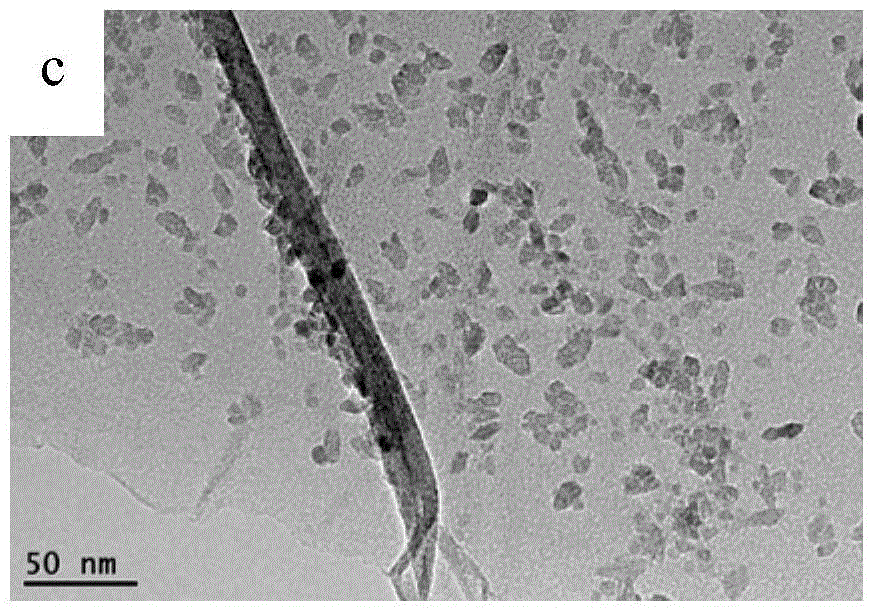

[0065] (1) TiO 2 -Preparation of graphene composite materials

[0066]Take 1g of graphene oxide and 5mL of deionized water and mix them with 250mL of absolute ethanol, sonicate for 15 minutes to obtain a brown-black suspension solution, and then add 7.5g of butyl titanate dropwise to the suspension under strong stirring conditions and then heat up to Reaction at 80°C. After reacting for 5 hours, the reaction liquid was cooled to room temperature, filtered, and washed until the washing liquid was close to neutral to obtain TiO 2 - Graphene oxide nanocomposites, the TiO 2 -Graphene oxide nanocomposites suspended in 200mL of purified water to obtain TiO 2 - Suspension system of graphene oxide nanomaterials.

[0067] Add the above to include TiO 2 -The suspension system of graphene oxide nanomaterials is all moved into the autoclave, and then 1g of ascorbic acid is added. After sealing it well, it is placed in a high-temperature blast drying oven, placed at 170°C for 24 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com