Method for preparing organic perovskite methyl amino lead iodide film by two-step method

A technology of methylamine lead iodide and methylamine iodide, which is applied in the field of two-step preparation of organic perovskite methylamine lead iodide thin films, which can solve the difficult-to-control and unsuitable large-area thin film preparation industry Production and practical application and other issues, to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

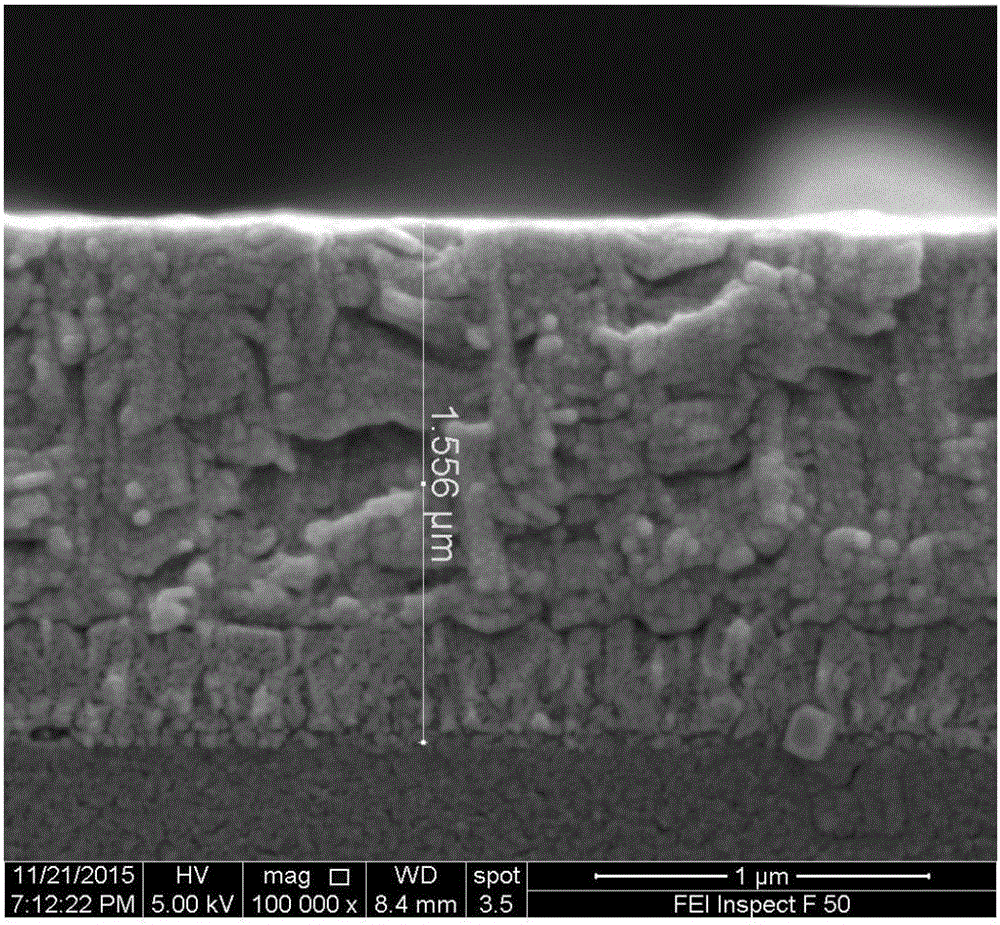

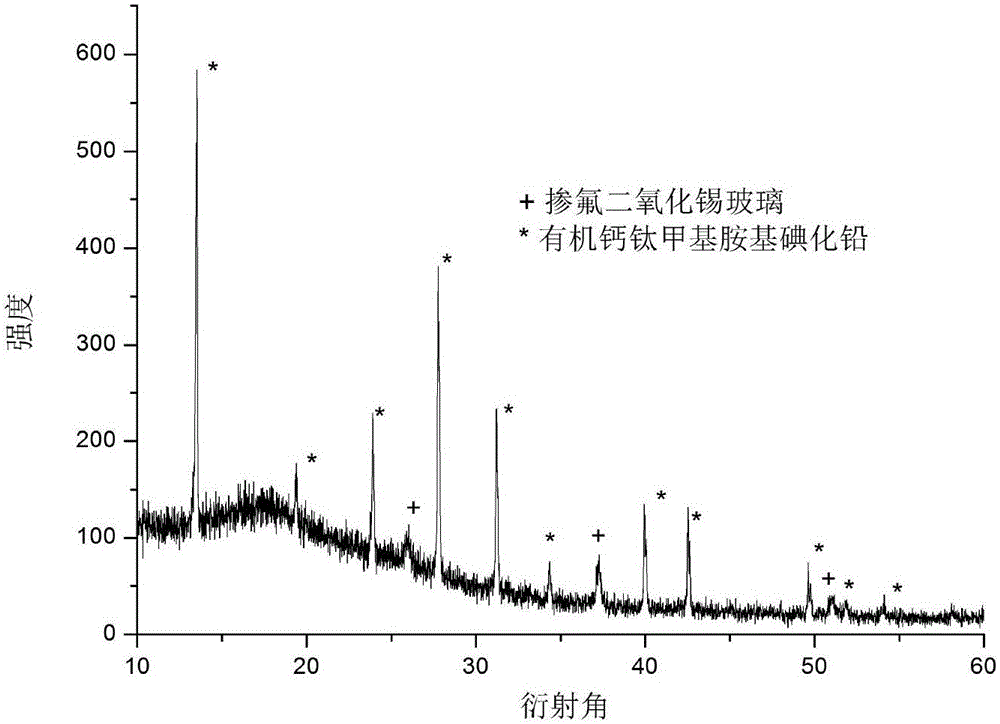

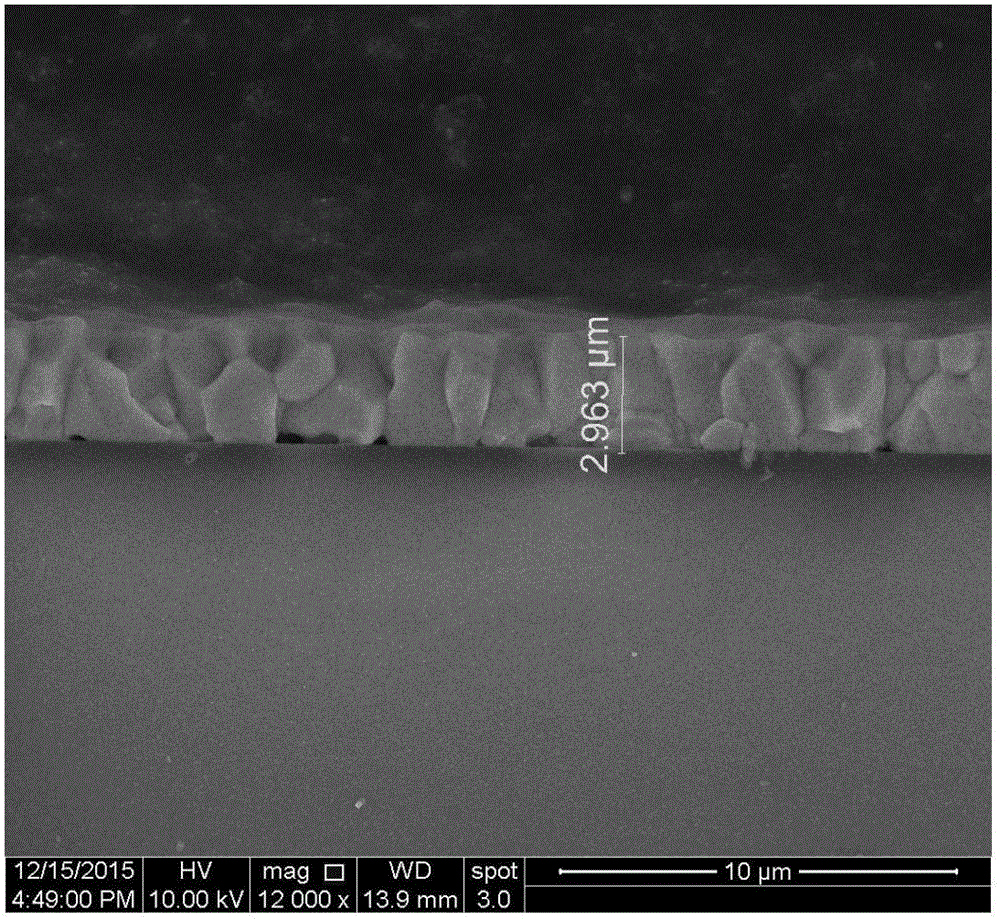

[0021] Using pulsed laser deposition technology, the cavity vacuum is 10 -3 Pa, laser energy 400 millijoules, pulse number 1000 pulses, using lead iodide as the target material to grow lead iodide film on fluorine-doped tin dioxide film, the film thickness is about 1.6 microns ( figure 1 ), put the grown lead iodide and methyl ammonium iodide powder into a tube furnace and heat at a constant temperature of 180 degrees Celsius for 20 minutes, allowing the methyl amine iodide atmosphere to react with the lead iodide film on the substrate to generate methylamine Lead iodide thin film, utilize X-ray diffraction to confirm that the thin film that this method grows is the organic perovskite methylamine lead iodide thin film of pure phase ( figure 2 ), using a scanning electron microscope to observe the cross-section to determine that the thickness of the film is about 3 microns, the crystal grains are very large, and basically run through the thickness of the entire film ( image ...

Embodiment example 2

[0023] Using magnetron sputtering technology, the chamber vacuum is 10 -3 Pa, sputtering power 150 watts, growth time 20 minutes, use lead iodide as target material to grow lead iodide film on fluorine-doped tin dioxide film, film thickness 500 nanometers, grow good lead iodide and methyl iodide Put the amine powder into a tube furnace and heat it at a constant temperature of 180 degrees Celsius for 15 minutes, so that the methylamine iodide atmosphere reacts with the lead iodide film on the substrate to form an organic perovskite methylamine lead iodide film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com