Cobaltosic oxide nanowire/reduction-oxidization graphene hydrogel composite material and preparation method and application therefor

A technology of cobalt trioxide nanometer and graphene hydrogel, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., and can solve the problems of low specific capacitance, unrevealed excellent performance, easy agglomeration and stacking of graphene, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

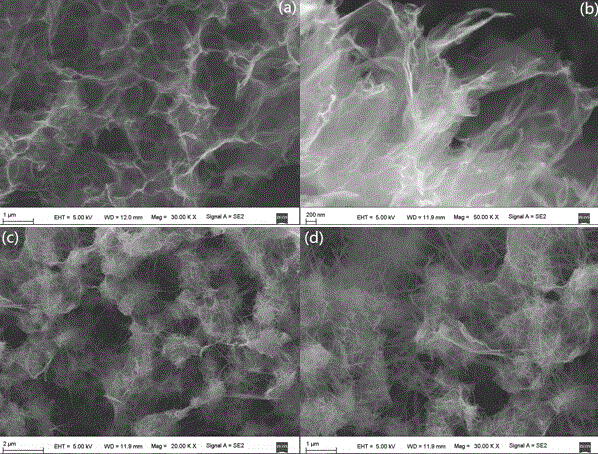

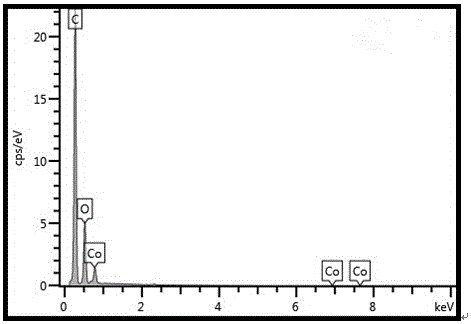

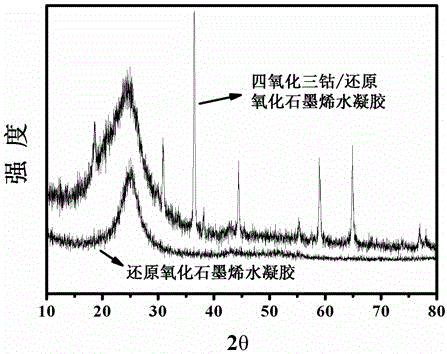

[0049] 1. Preparation of cobalt trioxide nanowires / reduced graphene oxide hydrogel composites

[0050] (1) Preparation of graphite oxide: GO was prepared by the Hummers method using natural graphite as raw material. The specific process is: 4g of graphite powder is added to 96mL of concentrated sulfuric acid, and the resulting mixture is stirred in an ice-water bath for 30 minutes, and then 13g of KMnO is gradually added to the reaction system. 4 and 2gNaNO 3 , while maintaining the process temperature below 20°C, the ice bath was removed after 30min, and the mixture was stirred for 3h at room temperature. As the reaction progressed, the mixture gradually became viscous and the color gradually changed to brown. Subsequently, 140 mL of distilled water was added and the temperature was kept not higher than 98° C., at which time the color of the mixture turned brown, and the reaction continued for 25 min. With the addition of 140 mL of distilled water and 10 mL of 30% hydrogen...

Embodiment 2

[0059] 1. Preparation of cobalt trioxide nanowires / reduced graphene oxide hydrogel composites

[0060] (1) Preparation of graphite oxide: same as Example 1;

[0061] (2) Preparation of graphene oxide dispersion: same as Example 1;

[0062] (3) Preparation and stripping of cobalt hydroxide: 0.0686g of p-aminobenzoic acid (PABA) was dissolved in distilled water to form an aqueous solution; then 0.0389g of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ?6H 2 O), stirred to fully dissolve to obtain a mixed solution; adjust the pH to 9~10 with ammonia water, stir for 30min, and let stand for 12h; remove the supernatant, filter the precipitate, and wash with absolute ethanol and distilled water until Neutral, formed cobalt hydroxide intercalated with p-aminobenzoic acid, and then ultrasonically stripped it in water (ultrasonic electric power is 250W, ultrasonic time is 15min), to obtain positively charged cobalt hydroxide nanoparticle dispersion;

[0063](4) Preparation of the composit...

Embodiment 3

[0068] 1. Preparation of cobalt trioxide nanowires / reduced graphene oxide hydrogel composites

[0069] (1) Preparation of graphite oxide: with embodiment one;

[0070] (2) Preparation of graphene oxide dispersion: same as Example 1;

[0071] (3) Preparation and stripping of cobalt hydroxide: 0.0686g of p-aminobenzoic acid (PABA) was dissolved in distilled water to form an aqueous solution. Then add 0.0824g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ?6H 2 O), stir to fully dissolve to obtain a mixed solution; adjust the pH value to 9~10 with a certain amount of ammonia water, and stir for 30 minutes. After standing for 12 hours, remove the supernatant, filter the precipitate with suction, wash with absolute ethanol and distilled water until neutral, and form cobalt hydroxide intercalated with p-aminobenzoic acid, and then perform ultrasonic stripping in water (The ultrasonic electric power is 250W, and the ultrasonic time is 15min), and positively charged cobalt hydroxide nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com