Preparation method of molybdenum disulfide-graphite-nickel phosphorus hydrogen evolution composite

A composite material, molybdenum disulfide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of improving the hydrogen evolution performance of molybdenum disulfide without increasing the ratio of edge/basal active sites Limited and limited engineering application value, etc., to achieve the effect of low preparation cost, simple molding process and good reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

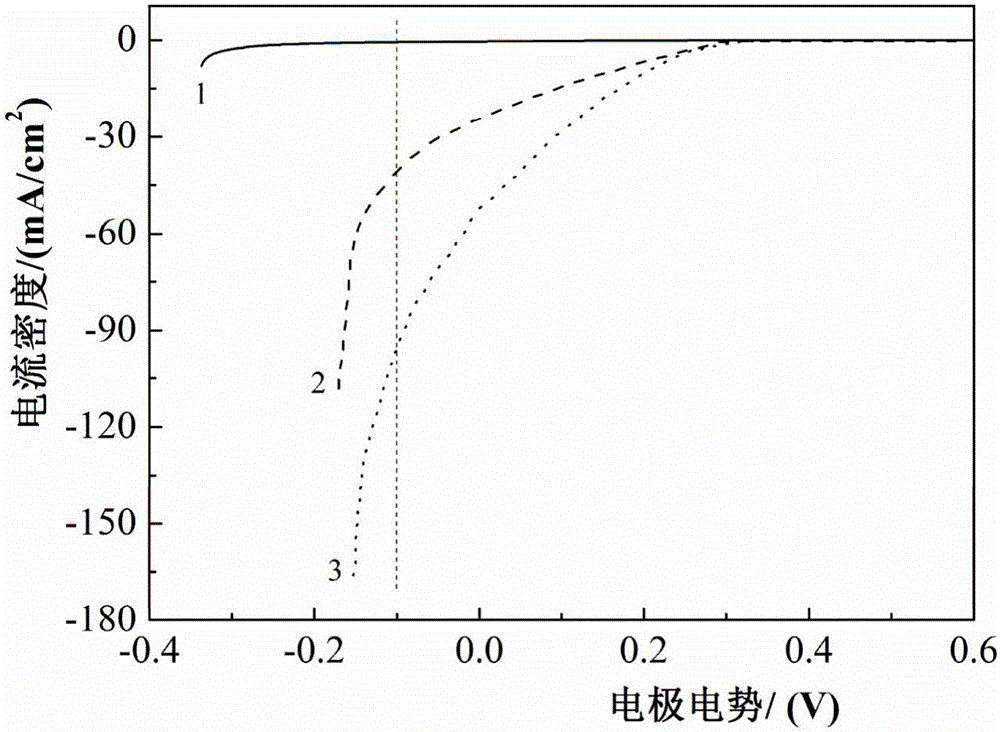

Image

Examples

Embodiment 1

[0044] (1) Pretreatment of graphite powder:

[0045] First, 5g of graphite powder with an average particle size of 0.5μm is added to a beaker containing 250mL distilled water, heated and boiled for 3h, then the suspension solution is naturally cooled to room temperature, and the graphite powder is collected by filtration; 5g of the collected graphite powder is put into 50g mass percent concentration Soak in 3% nitric acid solution for 30 minutes, then centrifuge the graphite powder, and centrifugally wash the graphite powder with distilled water until the washing water is neutral; then place the washed graphite powder in an oven and dry at 80°C. Grind it into an ultrafine powder with an average particle size of 0.5 μm with an agate mortar;

[0046] (2) preparation of graphite-nickel phosphorus powder used electroless plating solution:

[0047] Add 25g of nickel sulfate, 10g of citric acid, 3g of succinic acid, 3g of sodium acetate and 3g of ammonium bifluoride into a beaker f...

Embodiment 2

[0056] (1) Pretreatment of graphite powder:

[0057] First, 5g of graphite powder with an average particle size of 0.5μm is added to a beaker containing 250mL distilled water, heated and boiled for 3h, then the suspension solution is naturally cooled to room temperature, and the graphite powder is collected by filtration; 5g of the collected graphite powder is put into 50g mass percent concentration Soak in 3% nitric acid solution for 30 minutes, then centrifuge the graphite powder, and centrifugally wash the graphite powder with distilled water until the washing water is neutral; then place the washed graphite powder in an oven and dry at 80°C. Grind it into an ultrafine powder with an average particle size of 0.5 μm with an agate mortar;

[0058] (2) preparation of graphite-nickel phosphorus powder used electroless plating solution:

[0059] Add 27g of nickel sulfate, 12g of citric acid, 3.5g of succinic acid, 3.6g of sodium acetate and 3.5g of ammonium bifluoride into a be...

Embodiment 3

[0067] (1) Pretreatment of graphite powder:

[0068] First, 5g of graphite powder with an average particle size of 0.5μm is added to a beaker containing 250mL distilled water, heated and boiled for 3h, then the suspension solution is naturally cooled to room temperature, and the graphite powder is collected by filtration; 5g of the collected graphite powder is put into 50g mass percent concentration Soak in 3% nitric acid solution for 30 minutes, then centrifuge the graphite powder, and centrifugally wash the graphite powder with distilled water until the washing water is neutral; then place the washed graphite powder in an oven and dry at 80°C. Grind it into an ultrafine powder with an average particle size of 0.5 μm with an agate mortar;

[0069] (2) preparation of graphite-nickel phosphorus powder used electroless plating solution:

[0070] 28g nickel sulfate, 14g citric acid, 4g succinic acid, 4.4g sodium acetate and 4.5g ammonium bifluoride are added successively in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com