Nanofiber membrane capable of filtering out impurities and preparation method and application thereof

A technology of nanofiber membrane and nanofiber layer, which is applied in fiber processing, textiles, papermaking, nonwovens, etc., can solve the problems of unfavorable industrial production, filtration efficiency of only 80-90%, and complicated preparation of spinning solution. Achieve the effect of low price, not easy to break, and good sun resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

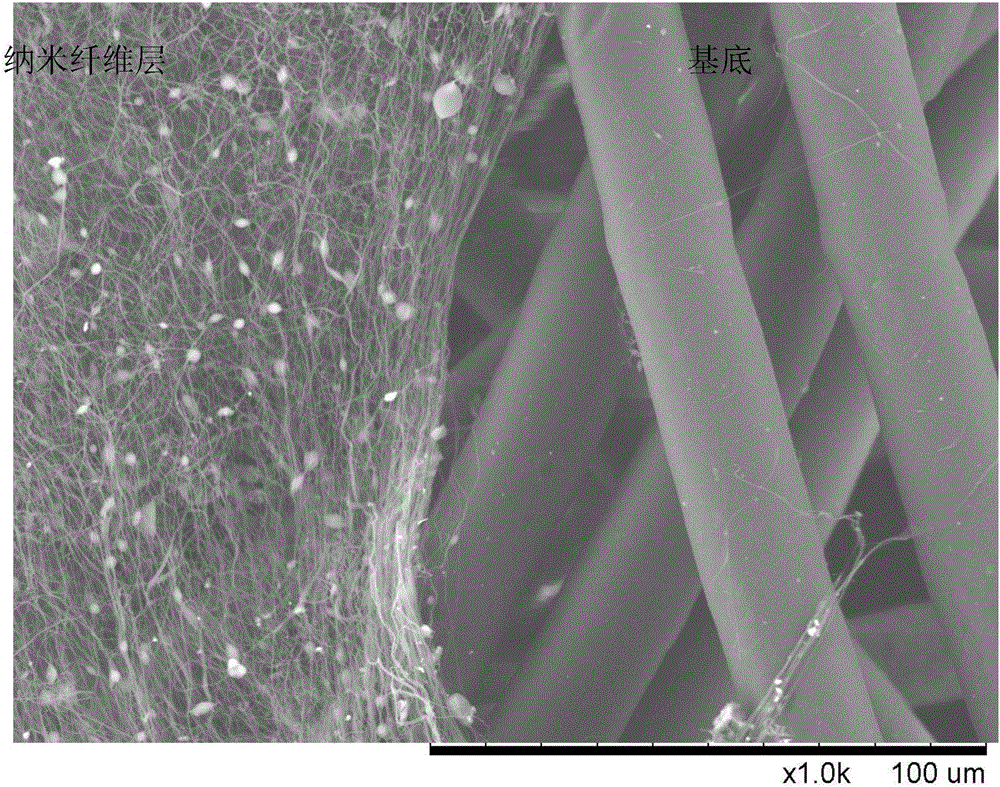

[0027] Take by weighing the polyacrylonitrile that quality is 5g and dissolve in 20ml dimethylformamide solution (obtaining the spinning solution that mass fraction is 25%), after it dissolves completely, inject in the liquid storage tank (injection rate is 0.5ml / min), add a positive pressure of 50kv to the spinning end of the needle electrospinning equipment, and a negative pressure of 40kv to the receiving end for electrospinning, adjust the positive and negative voltage difference to 90kv, and adjust the spinning needle and the receiving substrate The distance between them is 20cm, the ambient temperature and humidity are adjusted to 15°C and 30% respectively, and the non-woven fabric is used as the receiving substrate, that is, the grammage is 3.82g / cm2 A nanofibrous membrane that can filter out impurities. Such as figure 1 Shown is the surface scanning electron microscope (SEM) figure of the polyacrylonitrile nanofiber membrane that the present embodiment prepares gained...

Embodiment 2

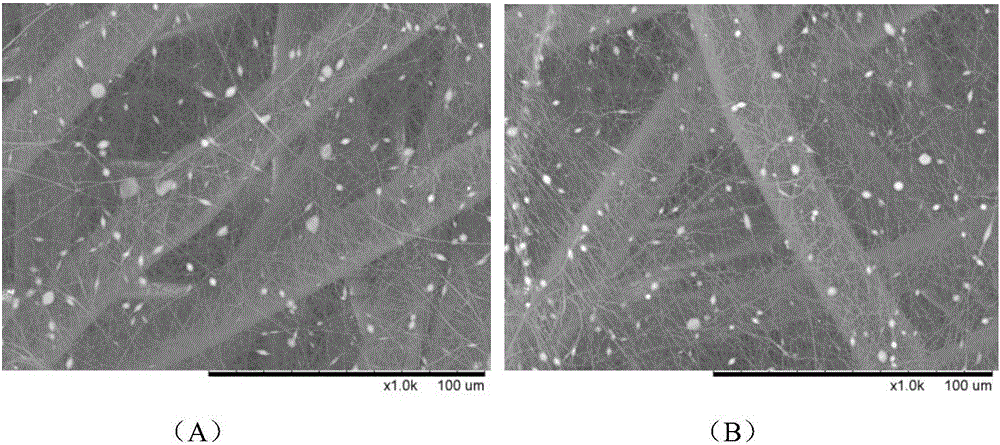

[0029] The polyvinylidene fluoride that weighs 15g is dissolved in 150ml dimethylformamide and acetone mixed solution (obtaining the spinning solution that mass fraction is 10%), after it dissolves completely, inject in the liquid storage tank (injection solution) The rate is 1.5ml / min), and a positive pressure of 45kv is applied to the spinning end of the linear electrospinning equipment, and a negative pressure of 35kv is applied to the receiving end for electrospinning, and the positive and negative voltage difference is adjusted to 80kv, and the spinning The distance between the steel wire and the receiving substrate is 40cm, the temperature and humidity of the environment are adjusted to 30°C and 70% respectively, and the non-woven fabric is used as the receiving substrate to obtain an average diameter of 358nm and a gram weight of 2.18g / cm 2 A nanofibrous membrane that can filter out impurities.

Embodiment 3

[0031] The polycaprolactone that takes by weighing 20g is dissolved in 50ml trifluoroethanol solution (obtaining the spinning solution that mass fraction is 15%), after it dissolves completely, inject in the liquid storage tank (screw rotation speed is 100rpp), Add a positive pressure of 10kv to the spinning end of the spiral blade electrospinning equipment, and add a negative pressure of 40kv to the receiving end for electrospinning, adjust the positive and negative voltage difference to 50kv, and adjust the distance between the spinneret and the receiving substrate The spacing is 30cm, the ambient temperature and humidity are adjusted to 20°C and 50% respectively, and the non-woven fabric is used as the receiving substrate to obtain an average diameter of 520nm and a gram weight of 2.88g / cm 2 A nanofibrous membrane that can filter out impurities.

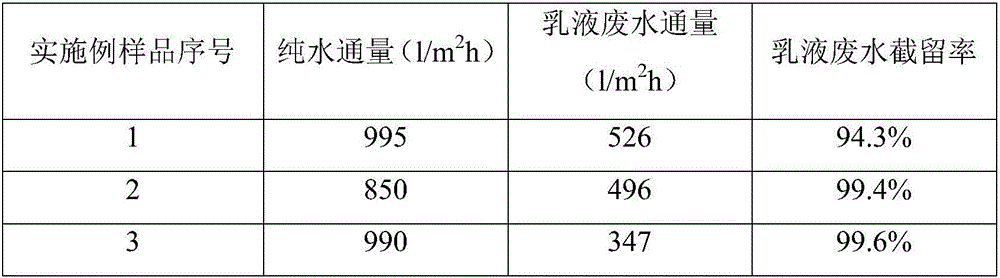

[0032] Table 1 is the air filtration efficiency and air resistance data of the nanofiber membranes prepared under the conditions...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wind resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com