Preparation method of antibacterial metal organic framework composite nanofiber

A technology of composite nanofibers and metal organic frameworks, which is applied in the fields of alkali metal compounds, fiber treatment, chemical instruments and methods, etc., to achieve the effects of low cost, high efficiency and long-lasting antibacterial performance, and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

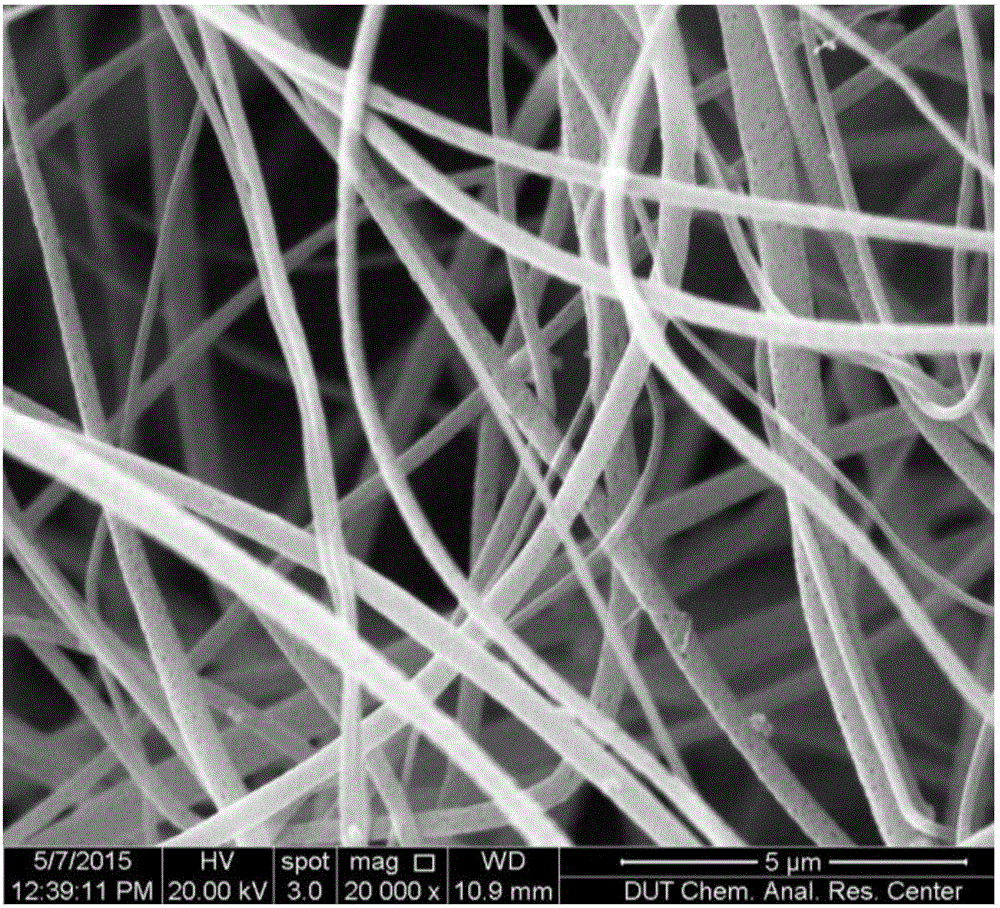

Image

Examples

Embodiment 1

[0020] Weigh 0.50g of AgNO 3 , 0.25 g of trimesic acid and 0.26 g of imidazole were mixed with 10 mL of deionized water, the pH value of the system was adjusted to 6.5 with sodium hydroxide, and magnetically stirred for 30 min. Pour the mixture into a polytetrafluoroethylene high-pressure reactor with a volume of 15 mL, seal it, heat it in a 120°C electric constant temperature drying oven, react for 4 hours, and place the reactor under cooling water to quickly cool to room temperature. The product was centrifuged, washed three times with high-purity water and absolute ethanol, and dried in vacuum at 60°C to obtain silver metal-organic framework particles. Weigh 0.50g of polyvinylpyrrolidone, add 20mL of dichloromethane, seal it, and disperse it completely under the action of ultrasonic waves, then add 0.25g of synthesized silver metal-organic framework nanoparticles, and continue to stir until the particles are completely dispersed to obtain a mixed solution Ⅰ . Take 2.00 g ...

Embodiment 2

[0023] Weigh 1.00g of AgNO 3 1.20 g of trimesic acid and 0.50 g of imidazole were mixed with 25 mL of water / ethylene glycol mixed solvent (volume ratio 1:0.5), the pH value of the system was adjusted to 6.5 with methylamine, and magnetically stirred for 30 min. Pour the mixture into a polytetrafluoroethylene high-pressure reactor with a volume of 50 mL, seal it, heat it in a 140°C electric constant temperature drying oven, react for 10 hours, and place the reactor under cooling water to quickly cool to room temperature. The product was centrifuged, washed three times with high-purity water and absolute ethanol, and dried in vacuum at 60°C to obtain silver metal-organic framework particles. Weigh 0.50g of polyoxyethylene lauryl ether, add 20mL of dichloromethane, seal it, and disperse it completely under the action of ultrasonic waves, then add 0.50g of synthesized silver metal-organic framework nanoparticles, and continue stirring until the particles are completely dispersed. ...

Embodiment 3

[0026] Weigh 2.00g of AgNO 3, 1.50 g of trimesic acid and 0.60 g of imidazole are mixed with 50 mL of water and N,N-dimethylformamide mixed solvent (volume ratio 1:1), and the pH value of the system is adjusted to 7 with triethylamine, Stir magnetically for 30 min. Pour the mixture into a polytetrafluoroethylene autoclave with a volume of 100 mL, seal it, heat it in a 140°C electric constant temperature drying oven, react for 24 hours, and place the autoclave under cooling water to quickly cool to room temperature. The product was centrifuged, washed three times with high-purity water and absolute ethanol, and dried in vacuum at 60°C to obtain silver metal-organic framework particles. Weigh 0.50g of polyvinylpyrrolidone, add 15mL of dichloromethane, seal it, and disperse it completely under the action of ultrasonic waves, then add 1.00g of synthesized silver metal-organic framework nanoparticles, and continue stirring until the particles are completely dispersed to obtain a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com