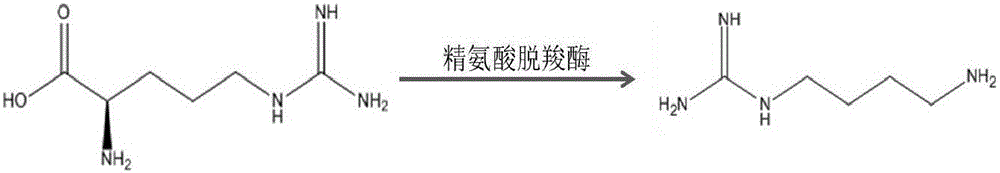

Arginine decarboxylase and application thereof

A technology of arginine decarboxylase and arginine, applied in the direction of application, enzyme, lyase, etc., can solve the problems of many steps, high cost, unsuitable for large-scale industrial production, etc., and achieve the effect of clear ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Containing the construction of arginine decarboxylase genetically engineered bacteria

[0038] Construct genetically engineered bacteria containing arginine decarboxylase as follows:

[0039] (1) Use primers 1 whose sequences are respectively shown in SEQ ID NO.3 and SEQ ID NO.4 by means of molecular biology:

[0040] 5'-CGGAATTCATGAATGATTGGTCTATTGATGAT-3' and Primer 2:

[0041] 5'-CCGCTCGAGTTAAGAAAAATCTTCTAAATAA-3' The arginine decarboxylase gene (amino acid sequence as shown in SEQ ID NO.2, nucleotide sequence as shown in SEQ ID NO.1) from Shewanella putrefaciens was amplified by PCR Addition: add rTaq enzyme to the system, pre-denature at 95°C for 5 minutes, denature at 94°C for 30 seconds, anneal at 55°C for 30 seconds, extend at 72°C for 2.0 minutes, 30 cycles, and finally extend at 72°C for 10 minutes;

[0042] (2) Digest the target gene and expression vector pET28a at 37°C for 4 hours with restriction enzymes EcoR I and Xho I;

[0043] (3) Ligate t...

Embodiment 2

[0046] Example 2: Induced expression of arginine deiminase

[0047] Induce the expression of genetically engineered bacteria as follows:

[0048] (1) Insert the genetically engineered bacteria of construction into LB slant medium and cultivate for 12h;

[0049] (2) Put a ring of slanted seeds into the LB medium and cultivate for 6 hours;

[0050] (3) Insert the seed solution into the LB fermentation medium and cultivate to OD 600 0.6, induced at three temperatures of 16, 25 and 37°C, adding IPTG with a final concentration of 0.05, 0.1, 0.2 and 0.4mmol / L, respectively, and collecting the bacteria after 4, 8, 10 and 16 hours of induction, and sterile physiological Bacteria were washed with salt water.

Embodiment 3

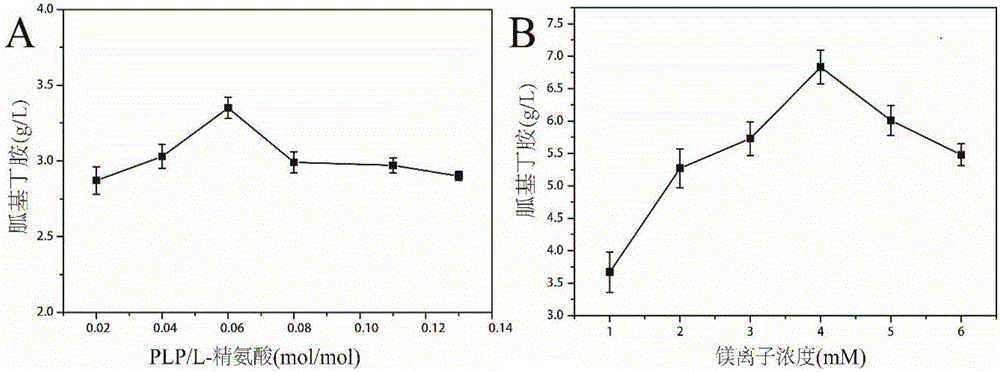

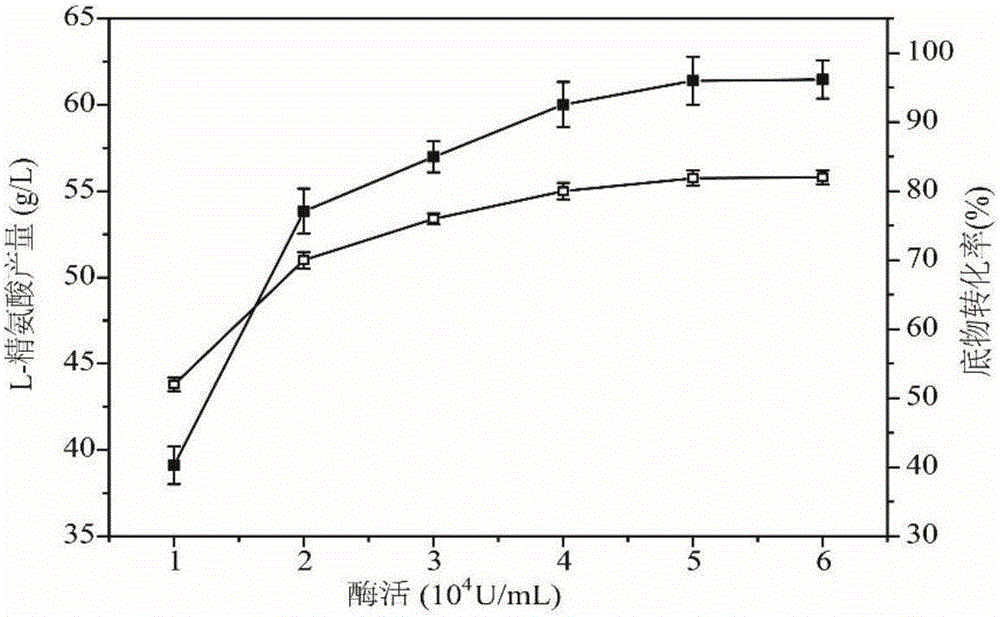

[0051] Embodiment 3: the impact of conversion conditions on the output of agmatine

[0052] Cultivate the genetically engineered bacterium constructed in Example 1, and induce it to express arginine decarboxylase, then collect the genetically engineered bacterium, and wash the thalline twice with sterile physiological saline;

[0053] The protein was purified using a nickel column, and the protein concentration was detected with a Bradford kit; different transformation systems were used to determine the content of agmatine in the transformation solution by high performance liquid chromatography.

[0054] (1) The transformation system is: pure enzyme 5.0×10 4 U / L, the substrate arginine concentration is 140g / L, the transformation temperature is 37°C, and the transformation time is 24h; under the transformation conditions, the yield of agmatine can reach 71.9g / L, and the average production intensity of the whole transformation process is 3.0g / (L·h), the conversion rate reached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com