Method for preparing plasma gold nanorod composite photocatalytic material with butterfly wing structure

A technology of composite photocatalysis and gold nanorods, which is applied in the field of preparation of ionic metal nanostructure composite photocatalytic materials, can solve problems such as few reports, and achieve the effects of low cost, wide selectivity range and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

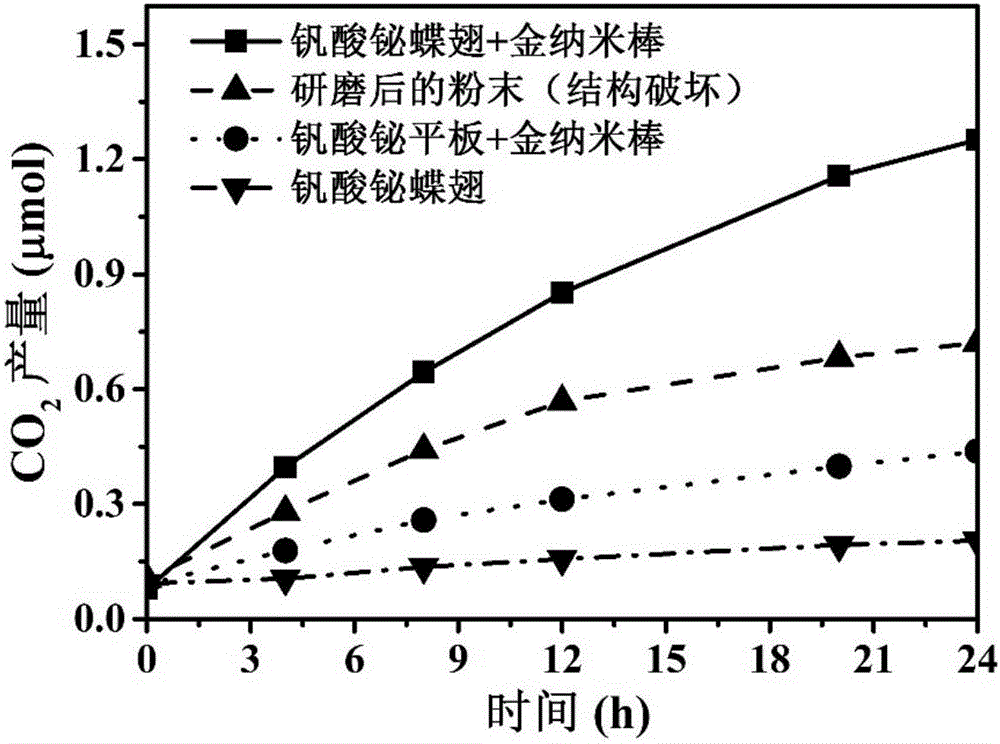

[0034] The invention provides a preparation method of multi-element metal oxide composite plasma gold nanorod with butterfly wing structure, which is used in the field of photocatalysis.

[0035] The specific method is as follows: 1) select different kinds of butterfly wings, and carry out pretreatment; the metal salt compounds of metal A and B are respectively dissolved in two kinds of organic solvents at a suitable temperature, and stirred until fully dissolved; Mix the organic solvents of metal salt compounds, and add an appropriate amount of P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide tri-block copolymer) or concentrated nitric acid, and stir and mix evenly at a specific temperature; 2 ) immersing the treated butterfly wing template in the above-prepared solution, and keeping it warm at a suitable temperature for a period of time; 3) taking out the above butterfly wing template, washing it four times with absolute ethanol, and drying it at a certain temp...

Embodiment 1

[0045] Choose the butterfly wings of the green papilio butterfly as the raw material, soak the butterfly wings in absolute ethanol for ten minutes, soak them in 2%-8% sodium hydroxide aqueous solution for 2-6 hours, and wash them with deionized water for several times. Dissolve bismuth nitrate and ammonium metavanadate in ethanol / acetic acid mixture and tetramethylammonium hydroxide solution respectively and mix them, then add 65% concentrated nitric acid and stir at 70°C until the solution is clear; Immerse the wing in the above solution, let it stand at room temperature for 12 hours, then take it out and wash it with ethanol for 4 times, then dry the butterfly wing at 60°C for 12 hours, and finally perform a high-temperature treatment on it at a heating rate of 1°C / min in an air atmosphere. After holding at ℃ for 4 hours, the bismuth vanadate material with the structure of the butterfly wing of Papilio viridis can be obtained.

[0046] Synthesize high-purity gold nanorods wi...

Embodiment 2

[0053] Select the butterfly wings of Papilionaceae as raw materials, first soak the butterfly wings in absolute ethanol for ten minutes, soak them in 2%-8% sodium hydroxide aqueous solution for 2-6 hours, and wash them several times with deionized water; add 10mmol / L titanium Acetyl acetone solution of tetrabutyl acetate, 100ml of ethanol / acetic acid solution of 10mmol / L strontium acetate were mixed, and then 4g of P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer) was added And stir at 70°C for 4 hours; soak the treated butterfly wings in the above solution, let it stand at room temperature for 8 hours, then take it out and wash it with ethanol for 4 times, then dry the butterfly wings at 100°C for 1 day, and finally dry them at 1°C in an oxygen atmosphere. It can be subjected to high-temperature treatment at a heating rate of 1 / min, and a strontium titanate material with a butterfly-wing structure can be obtained after holding at 600°C for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com