Bulk-shaped hydrophobic flexible silicon dioxide aerogel and preparation method thereof

A technology of hydrophobic silica and silica, applied in the direction of silica, silica, etc., can solve the problems of difficulty in obtaining bulk material, difficulty in forming bulk, shrinkage and cracking of skeleton, etc., and achieves short cycle and high porosity. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] One aspect of the present invention provides a method for preparing bulk hydrophobic silica airgel. The preparation method first reacts trialkoxysilane containing vinyl functional groups with mercaptan, then uses alcohols as solvents, adopts acid-base two-step catalysis, prepares wet gel through sol-gel, and then dries under normal pressure to obtain block silica airgel. Specifically, as an example, the preparation method of the present invention may include the following steps.

[0027](1) Mix vinyl-containing trialkoxysilane and mercaptan in a stoichiometric ratio and prepare trialkoxysilane containing C-S bond by heating or adding an initiator or ultraviolet irradiation. The stoichiometric ratio here refers to the stoichiometric ratio of addition reaction between mercaptan and vinyl group. If heating is adopted, the heating temperature may be 40-80° C., and the heating time may be 1-5 hours. If an initiator is added, the initiator may be azobisisobutyronitrile, di...

Embodiment 1

[0041] Weigh vinyltrimethoxysilane and 1,2-ethanedithiol in a stoichiometric ratio (molar ratio of 2:1) and mix them, stir and react at 60°C for 4h to obtain trimethoxysilane containing C-S bonds; 16.0g Trimethoxysilane containing C-S bond, mixed with 80.0g ethanol and added 5ml, 0.1mol L -1 hydrochloric acid and stirred for 2h; then added 5ml, 1mol·L -1 urea aqueous solution, stirred for 5min, and left to stand to obtain a gel;

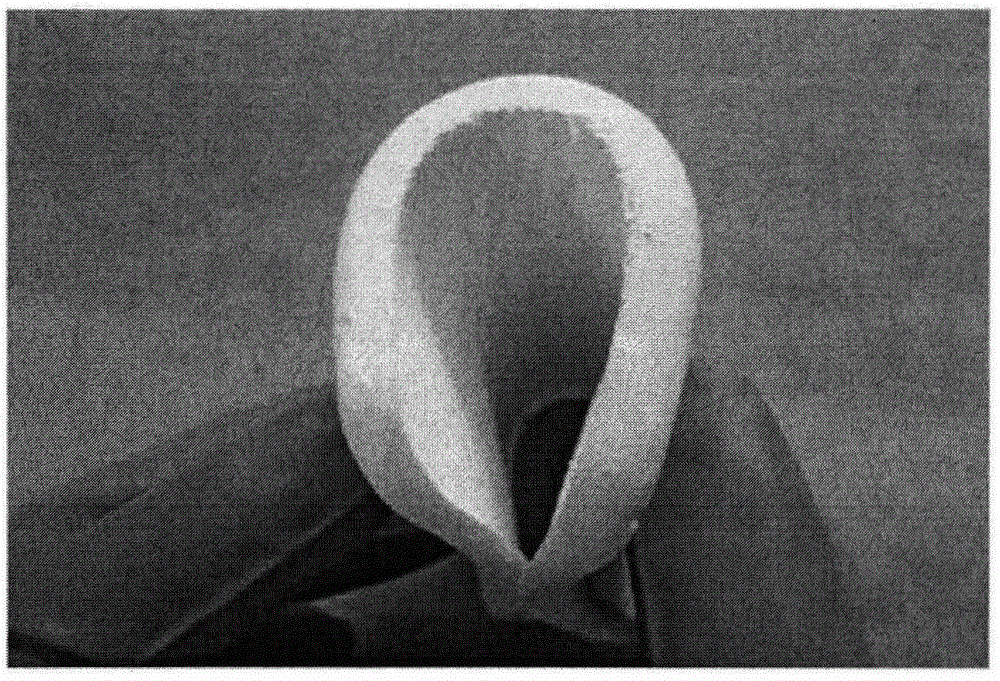

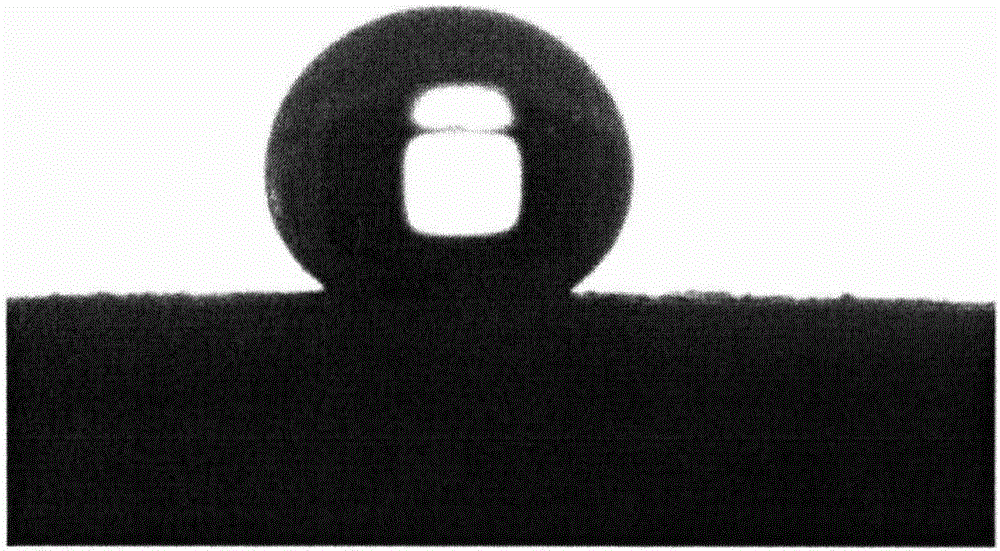

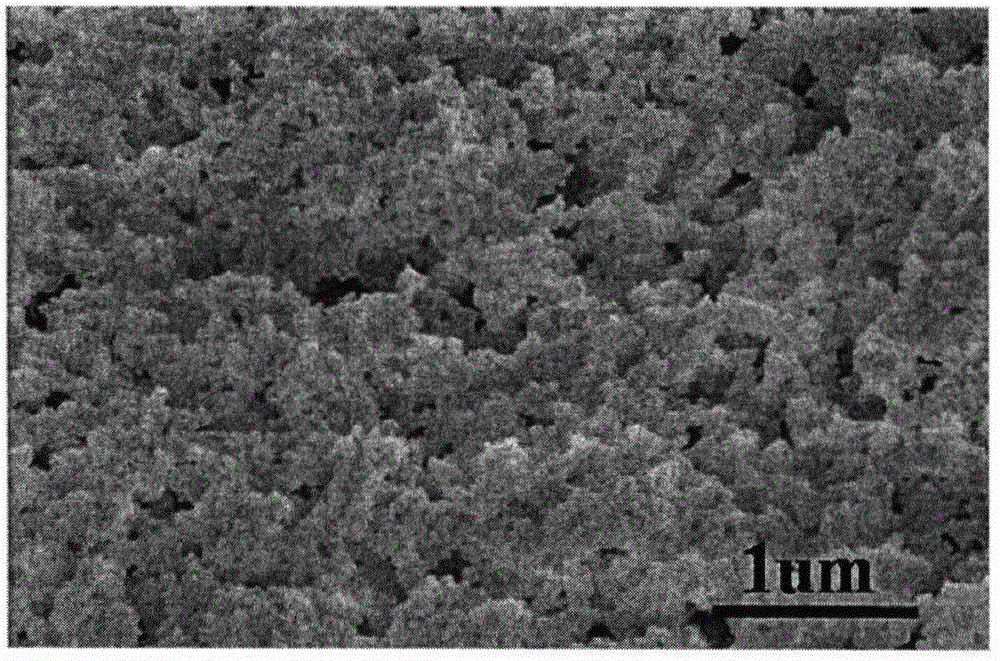

[0042] The gel obtained above was soaked in ethanol at 60° C. for 48 hours, and then dried at 80° C. under normal pressure for 2 hours to obtain a flexible silica airgel. The above flexible silica airgel has a density of 0.16 g cm -3 , porosity 91.1%, BET specific surface area 200m 2 g -1 , the contact angle between distilled water and the surface is 138°, the pore size distribution is 10-500nm, the compressive modulus is 0.37MPa, the flexural modulus is 0.05MPa, and the thermal conductivity is 0.036W·m -1 k -1 . Actual photos such as figure ...

Embodiment 2

[0044] Weigh vinyltrimethoxysilane and 1,8-octanedithiol in a stoichiometric ratio (molar ratio of 2:1) and mix them, and irradiate with ultraviolet light for 2 hours to obtain trimethoxysilane containing C-S bonds; 2.1 g of C-S bonds After mixing trimethoxysilane and 10.0g ethanol, add 0.7ml, 0.05mol·L -1 hydrochloric acid and stirred for 2h; then add 0.7ml, 1mol·L -1 ammonia water, stirred for 5min, and left to stand to obtain a gel;

[0045] The gel obtained above was soaked in ethanol at 40° C. for 24 hours, and then dried at 50° C. under normal pressure for 48 hours to obtain a flexible silica airgel. The above flexible silica airgel has a density of 0.18 g cm -3 , porosity 90.0%, BET specific surface area 240m 2 g -1 , the contact angle between distilled water and the surface is 148°, the pore size distribution is 10-200nm, the compressive modulus is 0.55MPa, the flexural modulus is 0.15MPa, and the thermal conductivity is 0.038W m -1 k -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com