Mutant gene TlXynA_2 of xylanase TlXynA and application thereof

A technology of xylanase and mutant gene, which is applied in the field of genetic engineering to achieve the effects of increasing digestion and absorption, a simple and practical method, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Construct the recombinant vector containing the mutant gene TlXynA_2 of xylanase TlXynA, the specific steps are as follows:

[0025] (1) Obtain the xylanase TlXynA gene from the NCBI database, connect the TlXynA gene and the plasmid pET28a to obtain the pET28a-TlXynA plasmid, and its nucleotide sequence is shown in SEQ ID NO.3. Using the above-mentioned recombinant plasmid as a template, design mutation primers for site-directed mutation. The primer sequences are as follows:

[0026]

[0027] The PCR amplification reaction system is as follows:

[0028]

[0029] The reaction procedure is as follows:

[0030]

[0031]

[0032] (2) Take 3 μL of the PCR product for agarose gel electrophoresis verification, leaving a reaction product with clear bands. The wild-type plasmid in the product was digested with DpnI restriction enzyme to ensure that the transformants in the subsequent steps were all mutants. The digestion system is as shown in the table below, mix ...

Embodiment 2

[0041] Construct the recombinant engineered bacterium that contains above-mentioned mutant gene TlXynA_2, concrete steps are as follows:

[0042] Add 2 μL of the above mutant plasmid with correct sequencing to 50 μL E. coli BL-21 competent cells, ice bath for 30 min; Centrifuge for 2 minutes, discard the supernatant (leave a little bottom liquid). Spread the remaining solution on an LB plate containing 50 μg / mL kanamycin, spread evenly until dry, and incubate overnight at 37°C; pick a single clone the next day, and inoculate it in 5 mL of LB medium containing antibiotics, at 37°C Cultivate overnight at 200rpm to obtain recombinant engineered bacteria containing the mutant gene TlXynA_2.

Embodiment 3

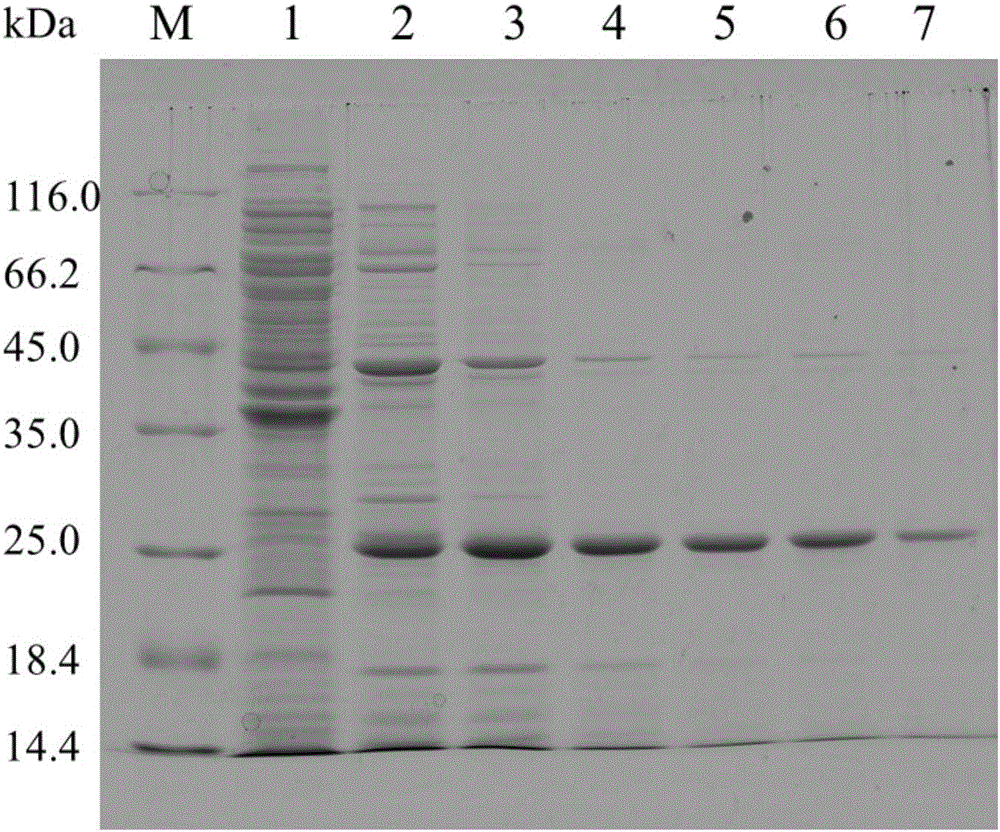

[0044] Fermentative expression and purification of the mutant xylanase TlXynA-R116QR161QR187S encoded by the above mutant gene TlXynA_2, the specific steps are as follows:

[0045] (1) Heterologous expression of recombinant protein:

[0046] 1. Get the recombinant engineered bacterium containing the above-mentioned mutant gene TlXynA_2 obtained in Example 2, and cultivate overnight at 37° C. 200 rpm in 5 mL LB medium (containing 50 μg / mL kanamycin);

[0047] ②Transfer the cultured bacterial solution overnight to a 1L Erlenmeyer flask filled with 300mL LB medium (containing 50μg / mL kanamycin), and incubate at 37°C for about 3h until OD 600 =0.6-0.8;

[0048] ③Add IPTG with a final concentration of 0.5mM, and induce culture at 20°C for 20h;

[0049] ④ Centrifuge at 8000rpm at 4°C for 10min to obtain bacterial pellet;

[0050] ⑤NaH with pH 8.0 2 PO 4 -Resuspend the bacteria in NaCl buffer, and place the bacteria in a 100mL centrifuge tube;

[0051] ⑥Put the centrifuge tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com