Preparation method of fluorine-containing hyperbranched multi-arm polyacrylamide polymer

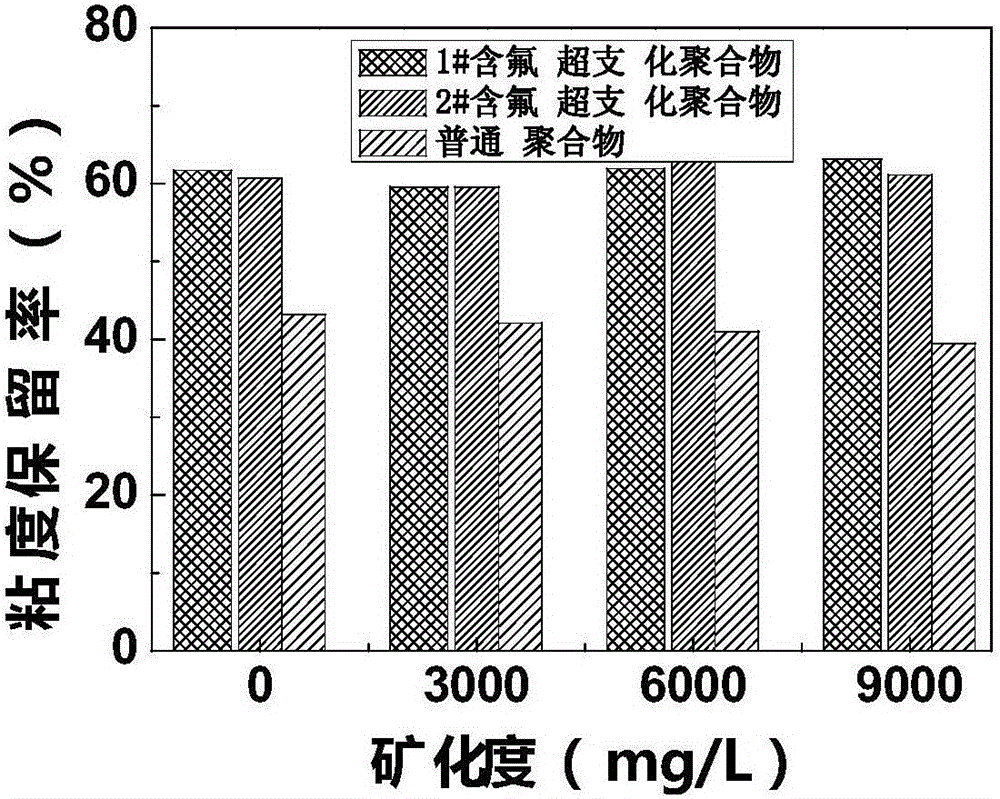

A polyacrylamide and hyperbranched polymer technology, applied in chemical instruments and methods, ether preparation, drilling compositions, etc., can solve the problems of affecting the effect of polymer flooding, structural instability, viscosity drop, etc., and achieve good salt resistance. The performance, the preparation method is simple, and the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, prepare the polyglycidyl ether HPG of terminal group rich in hydroxyl

[0048] Add 1,1,1-trimethylolpropane (TMP) (0.187g, 1.39mmol) into the three-necked flask, then dropwise add 0.11mL of 20wt% methanol solution of potassium methoxide (containing 22mg potassium methoxide), react for 20min, Methanol was removed in vacuo, and 20 mL of anhydrous dioxane was added. The temperature was raised to 95°C and 25mL (31.6g) of glycidol was added very slowly (approximately 10h completion). After the addition is complete, continue to react for 5 hours, add a large amount of methanol, pass through the cation column, and remove K+ , with a large amount of acetone precipitation methanol solution to obtain white solid HPG, suction filtration, freeze-drying to obtain product HPG (m=8~10), molecular formula is (C 3 h 8 o 3 ) m , where m is 9 and the branching ratio is 0.6.

Embodiment 2

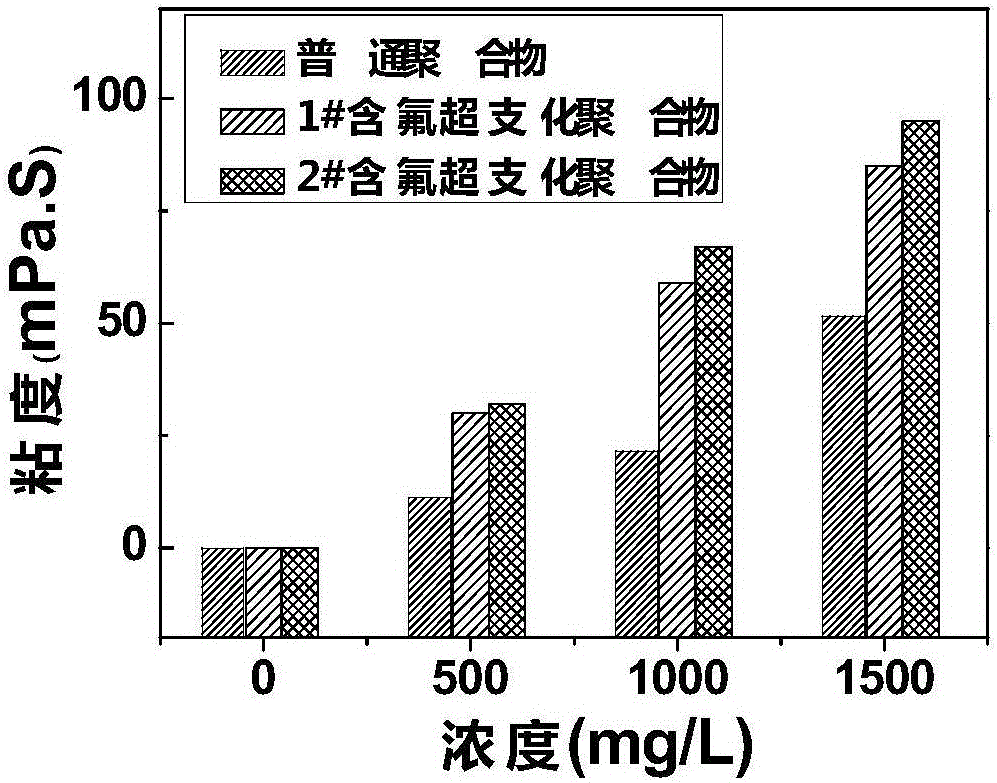

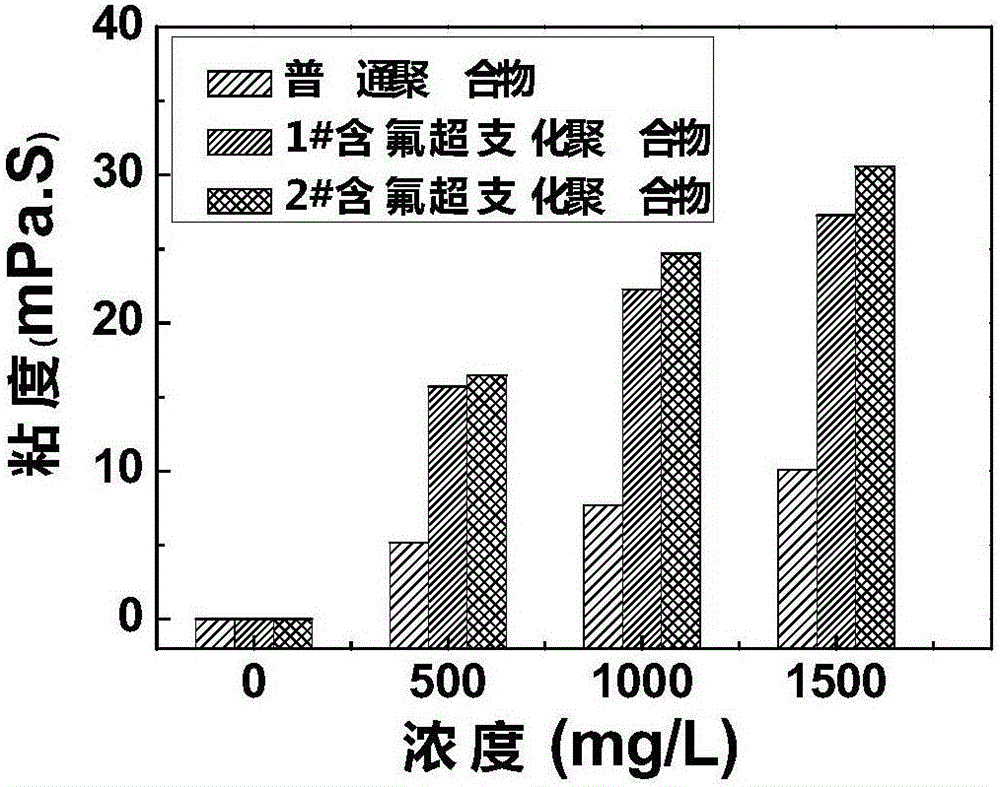

[0049] Embodiment 2, preparation fluorine-containing hyperbranched multi-arm polyacrylamide polymer

[0050] 30mg HPG, 85mL H 2 O was placed in a three-necked flask, stirred and dissolved, and nitrogen gas was introduced to deoxygenate for 45 minutes, then an aqueous solution of ammonium cerium nitrate (50 mg of ammonium cerium nitrate dissolved in 10 mL) was added under the protection of nitrogen, and the reaction was stirred at 40°C for 30 minutes. Add acrylamide aqueous solution (9.0g acrylamide dissolved in 20mL water), sodium acrylate aqueous solution (2.1g sodium acrylate dissolved in 8mL water), hexafluorobutyl methacrylate monomer emulsion (450mg hexafluorobutyl methacrylate mono The body emulsion was dissolved in 5 mL of water, the emulsifier was sodium lauryl sulfate (450 mg), an aqueous solution of acryloyl phosphorylcholine monomer (360 mg of acryloyl phosphorylcholine monomer was dissolved in 4 mL of water), and then heated to 55 ° C for 6 hours. The obtained rea...

Embodiment 3

[0052] Example 3, preparation of fluorine-containing hyperbranched multi-arm polyacrylamide polymer

[0053] 35mg HPG, 85mL H 2 O was placed in a three-necked flask, stirred and dissolved, and nitrogen gas was introduced to remove oxygen for 45 minutes, and then an aqueous solution of ammonium cerium nitrate (50 mg of ammonium cerium nitrate dissolved in 10 mL of water) was added under the protection of nitrogen, and the reaction was stirred at 40 ° C for 30 minutes. Slowly add acrylamide aqueous solution (10.5g acrylamide dissolved in 23.4mL water), sodium acrylate aqueous solution (2.45g sodium acrylate dissolved in 9.4mL water), hexafluorobutyl methacrylate monomer emulsion (525mg hexafluoromethacrylate Butyl ester monomer is emulsified in 5.8mL water, emulsifier is sodium lauryl sulfate 525mg), acryloyl carboxylate choline monomer aqueous solution (420mg acryloyl carboxylate choline monomer is dissolved in 4.6mL water), then heats up Reaction at 55°C for 6h. The obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com